Multi-speed driving gear hub for bicycles

A technology for bicycles and transmission wheels, which is applied to multi-ratio transmissions, transmission components, transmissions, etc. It can solve the problems of complex mechanical structures and high processing costs of transmission hubs, and achieve axial compression and compact structure and good handling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

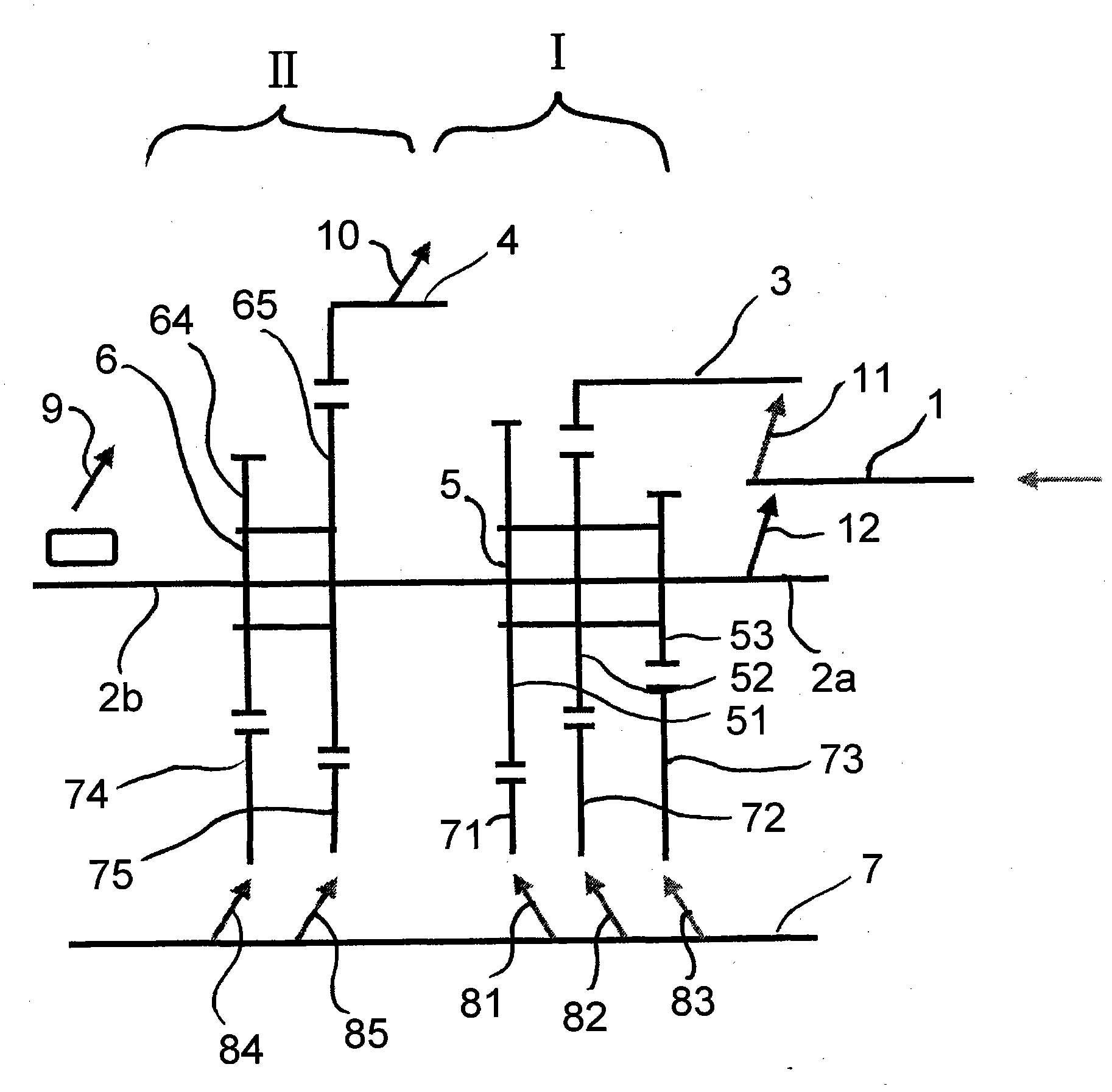

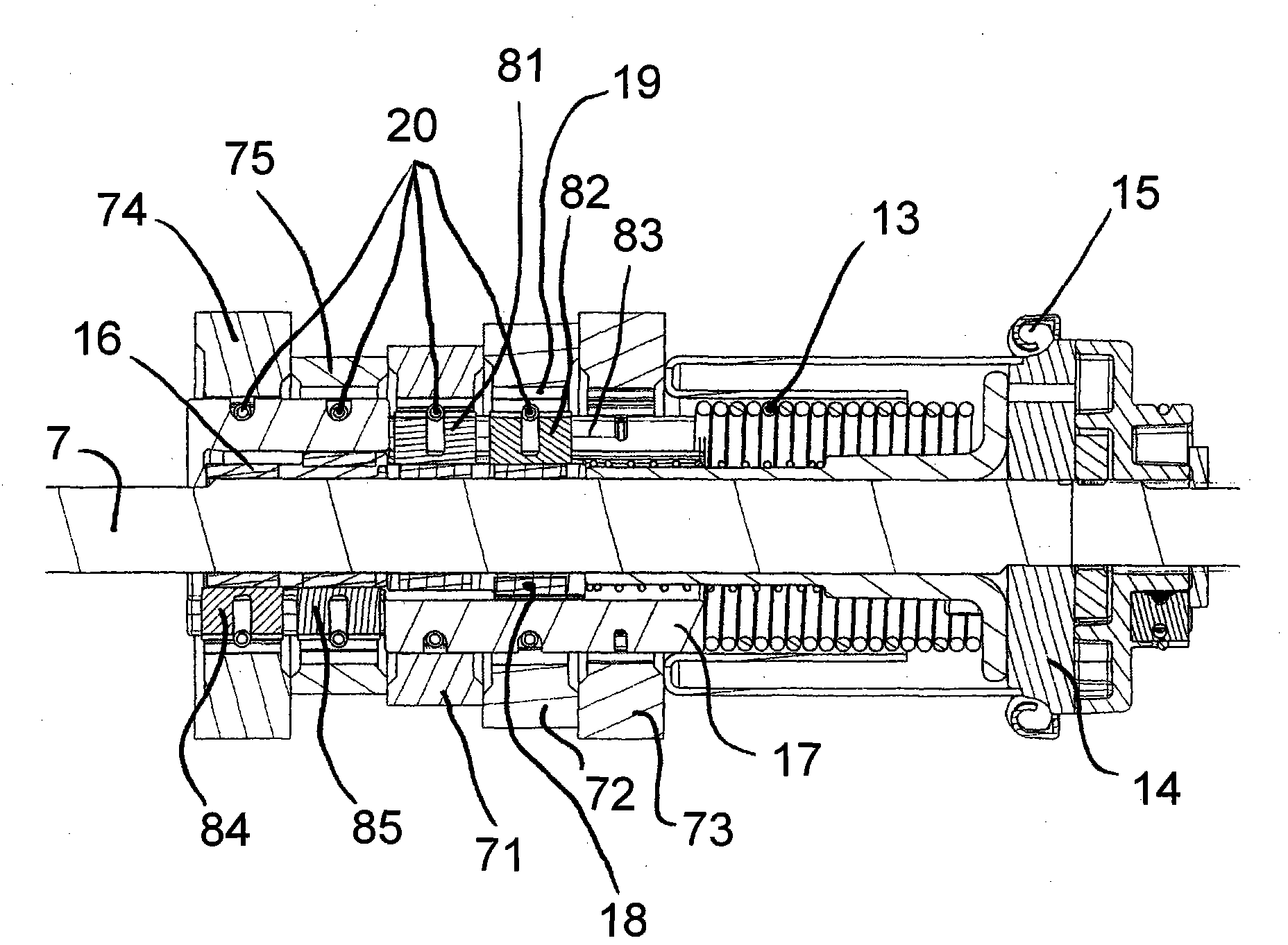

[0046] figure 1 A schematic diagram of a preferred embodiment of the drive hub according to the invention is shown, here only the half above the hub axle 7 including the hub axle 7 is shown. The hub axle is not shown.

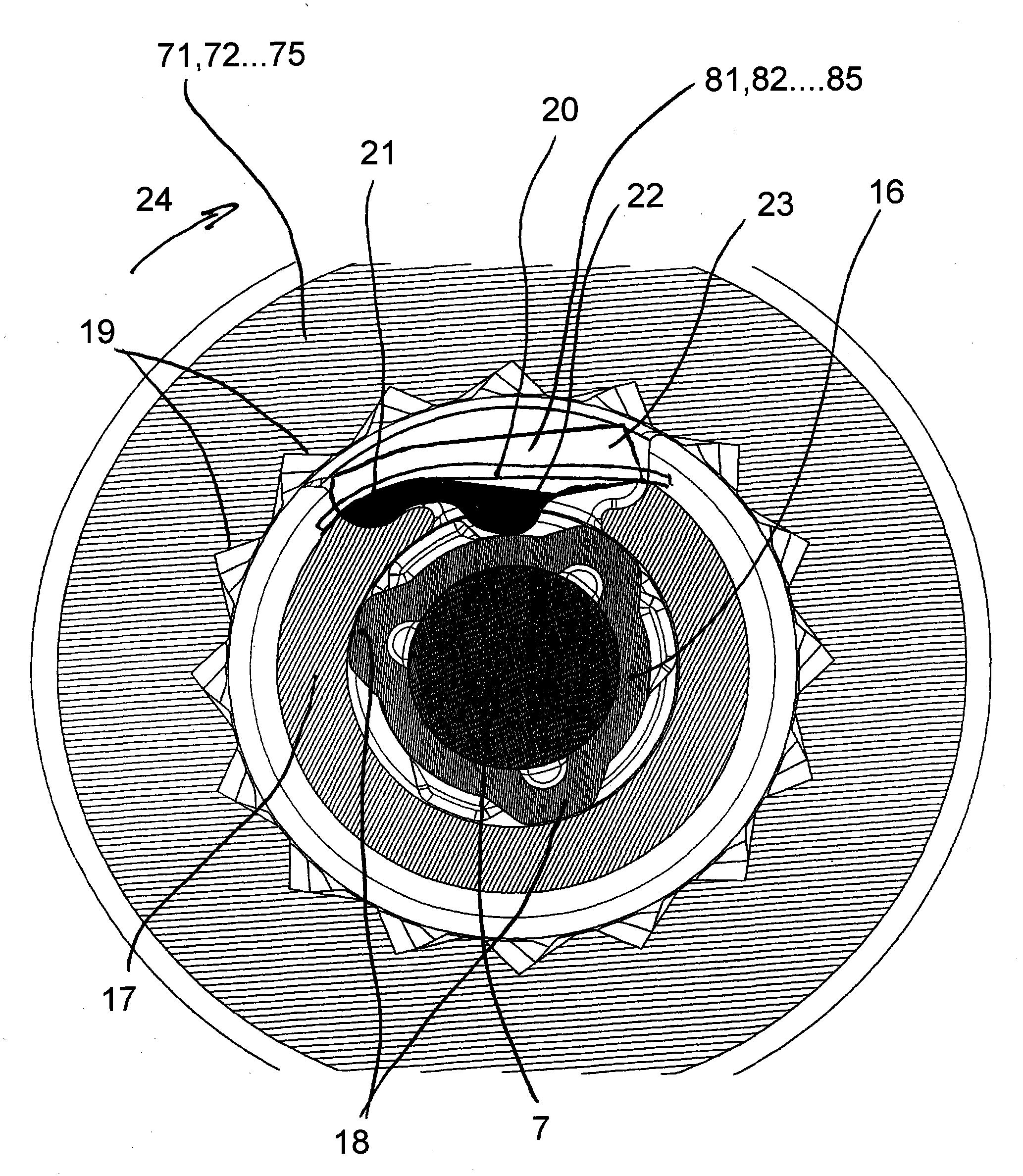

[0047] A drive movement is introduced at the drive element 1 , where, during the forward rotational movement, the rotation is carried via the drive element freewheel clutch 11 to the input of the first transmission stage I on the first ring gear 3 . The first-stage planetary gears 5 and the second-stage planetary gears 6 are mounted on the planetary gear carriers 2a and 2b. The first planetary gear stage 5 has a first planetary gear 51 , a second planetary gear 52 and a third planetary gear 53 , which are coupled to one another in a rotationally fixed manner. in accordance with figure 2 In the sectional view of , one planet gear 51 , 52 or 53 can be seen in each case. Of course, there are other circumferentially spaced planetary gears belonging to the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com