Classifier and method of operating the classifier

A classifier, classification zone technology, used in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

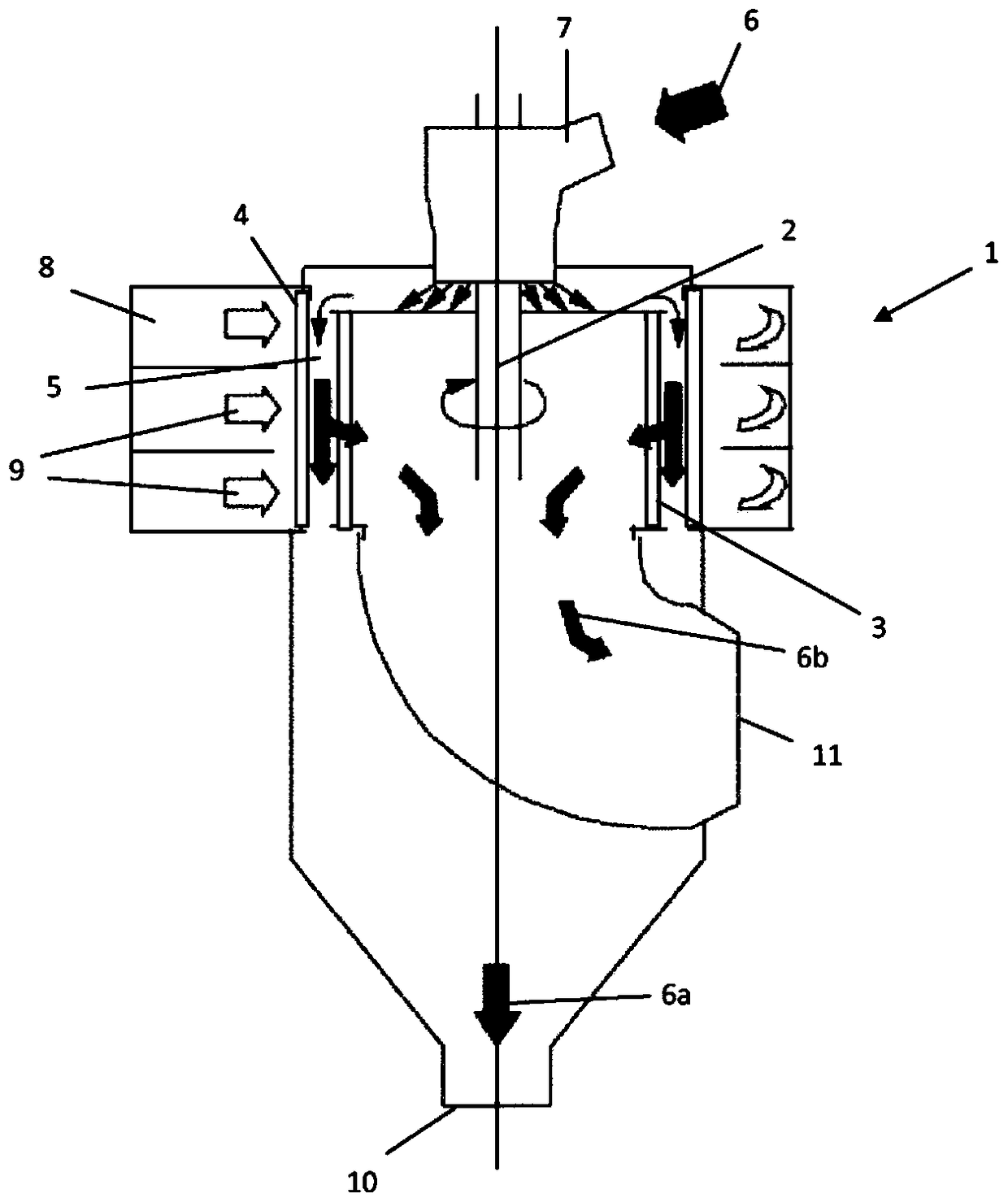

[0041] figure 1A classifier 1 is shown having a cylindrical drum 3 rotating about an axis of rotation 2 and an air guide system 4 arranged around the drum, wherein a classifying area 5 is formed between the drum and the air guide system. In the illustrated exemplary embodiment, the granular feed material 6 to be classified is fed onto the cover of the trommel 3 via a material feed 7 arranged above the trommel 3 . Classification air 9 is supplied to the classification area 5 via the classification air supply 8 and the air guide system 4 .

[0042] The feed material 6 fed onto the cover of the trommel 3 is pushed outward by centrifugal force and falls into the classification area 5 . The coarse material 6 a of the feed 6 falls to the bottom and is removed via the coarse material outlet 10 , while the fine material 6 b is led together with the classifying air 9 into the trommel 3 and ejected via the fine material outlet 11 .

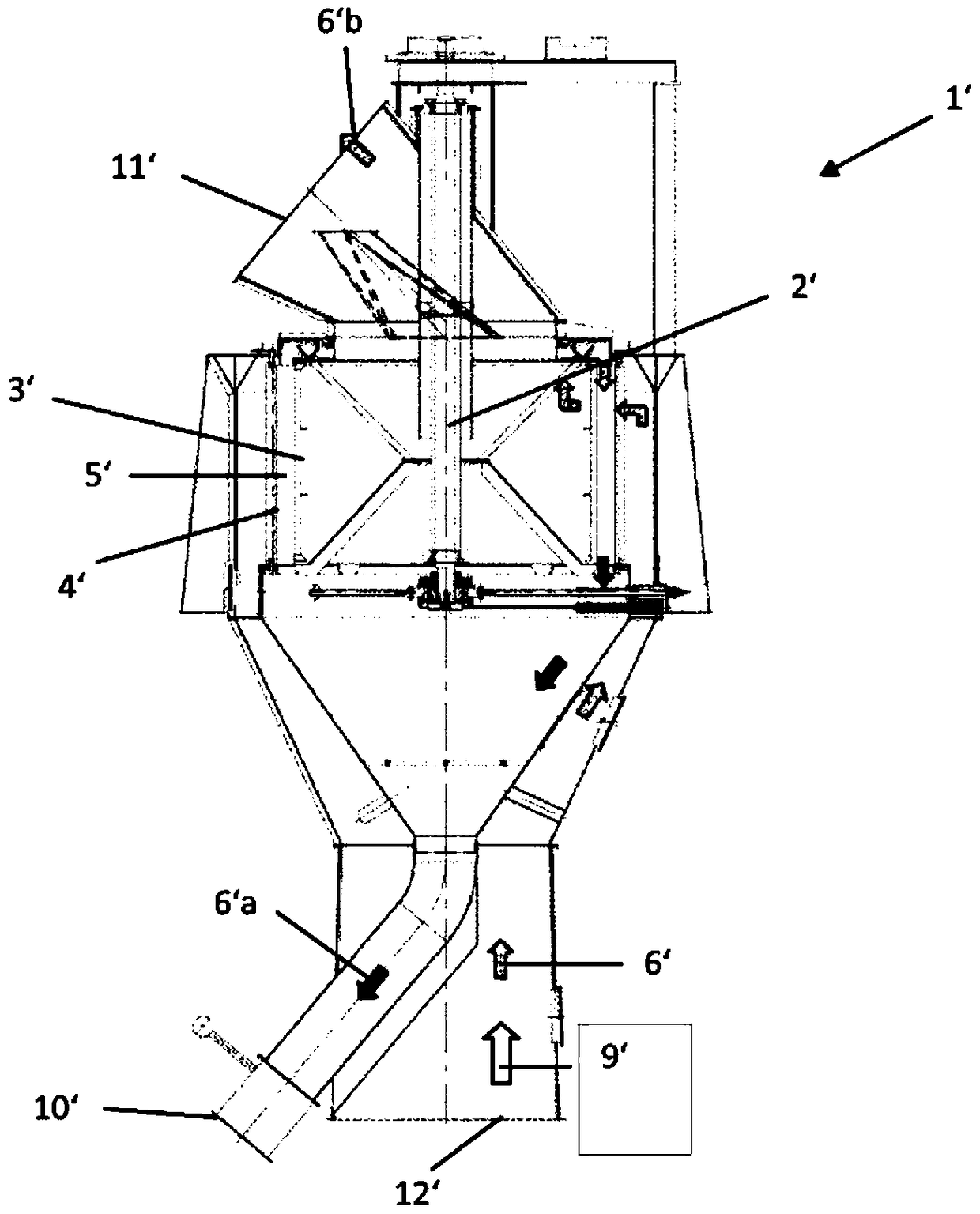

[0043] figure 2 Shows a classifier 1' according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com