Mobile sifter

A classifier and integrated technology, applied in the direction of solid separation, separating solids from solids with air flow, chemical instruments and methods, etc., can solve problems that do not involve classifiers, polluted products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

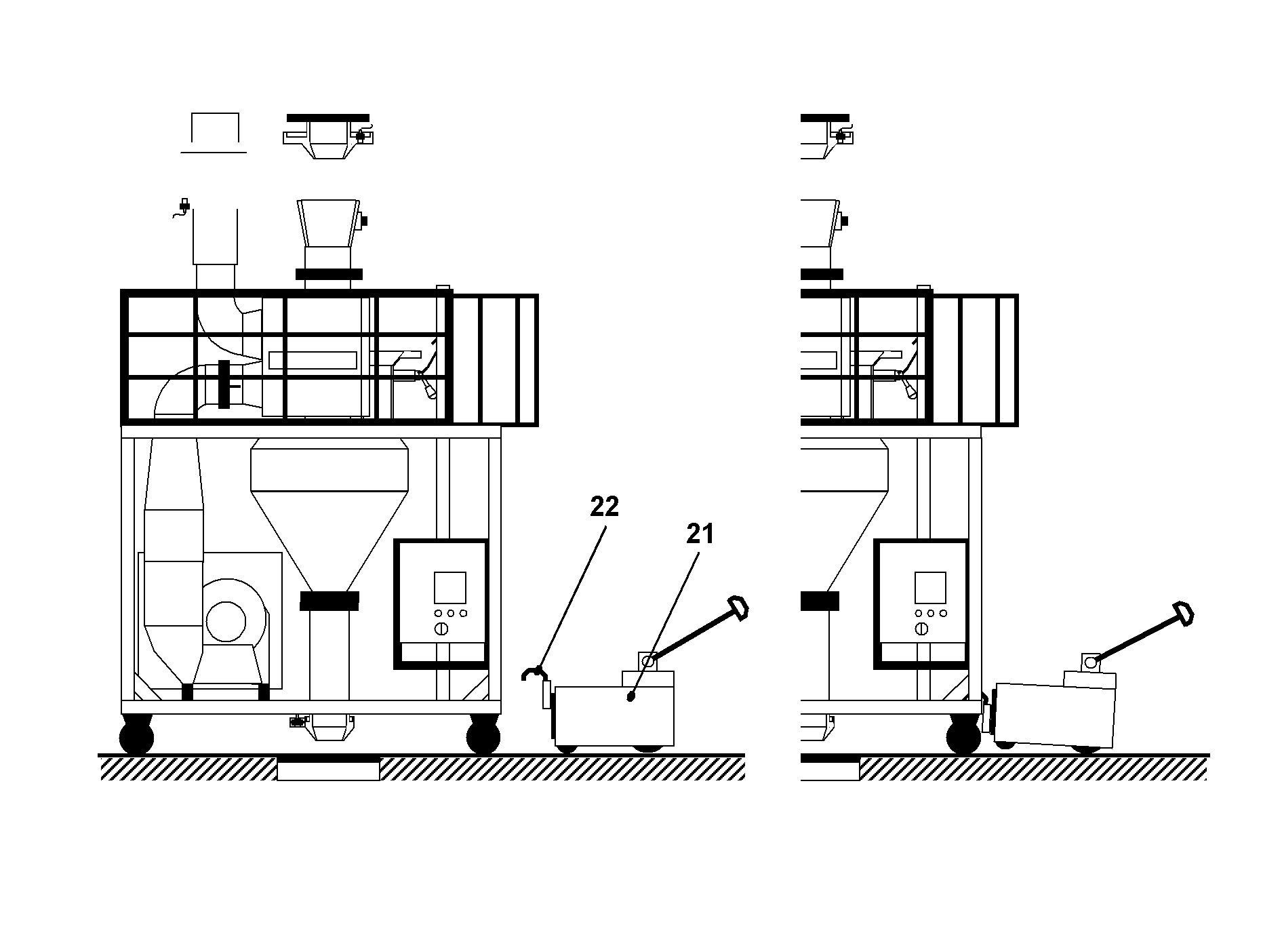

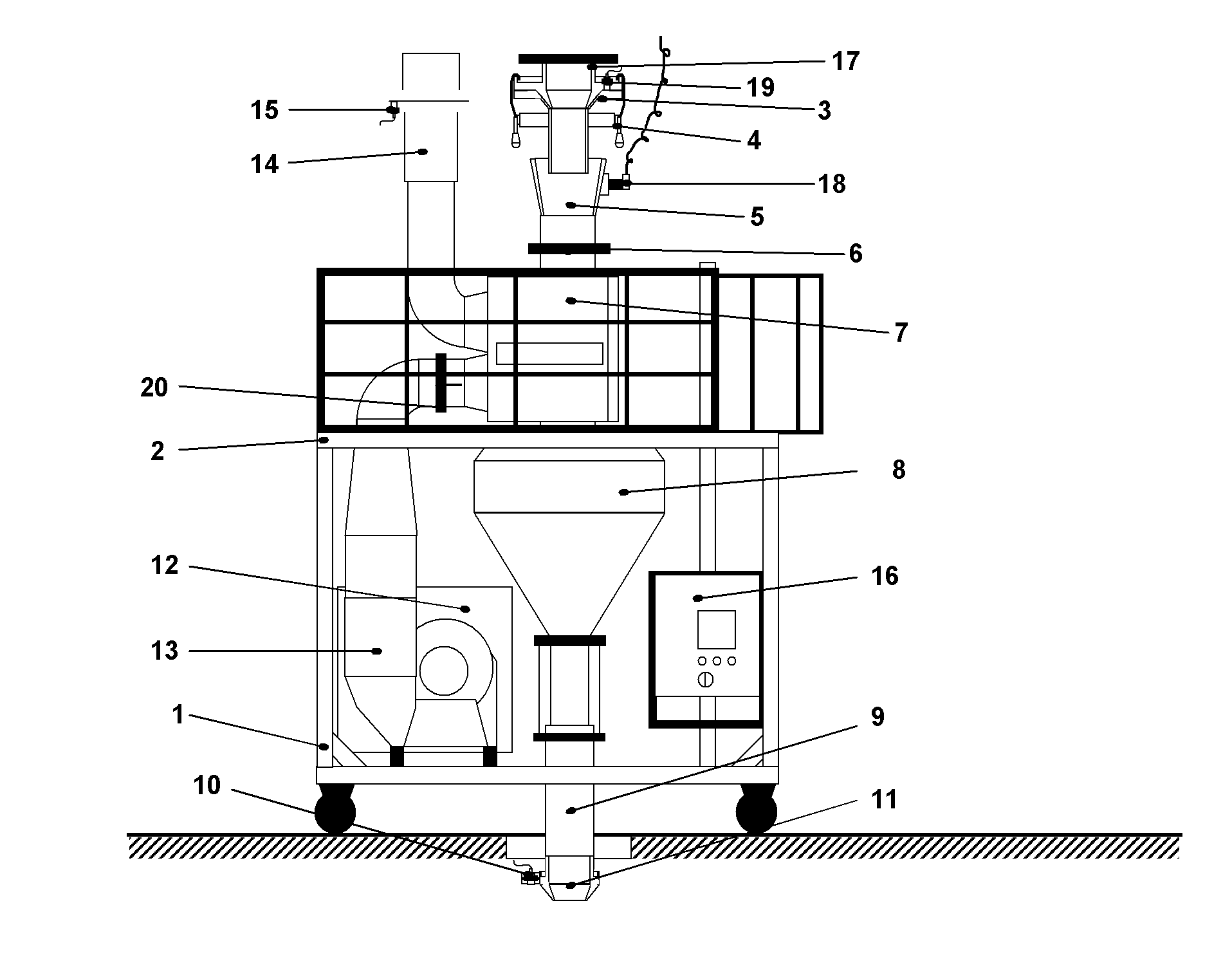

[0009] The problem with the prior art is how to provide a classifier by means of which the particles can be dedusted, which classifier is not fixed at one location but can be used mobile in the facility in order to achieve different operations. At the same time, the device should be designed such that it is possible to attach the device to the silo outlet in an ergonomic manner. A further object is to set up the procedure for manipulating the device such that individual operating parameters can be set based on a number of different grader positions in a reliable and user-friendly manner.

[0010] To further solve the problems in the prior art, the present invention provides a classifier from which most of the amount of residual particles previously transported into the classifier is removed from the classifier after the dedusting process is completed. removal, and any residual particles that may still be present in the classifier, are easily and reliably washed out of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com