Hydraulic system used for revolving jogging control on crawler crane

A technology of crawler crane and hydraulic system, applied in the field of hydraulic system, can solve the problems of unavailability, high slewing speed, potential safety hazards, etc., and achieve the effects of convenient operation, simple structure, guaranteeing safety and high efficiency

Inactive Publication Date: 2011-06-15

SHANGHAI SANY TECH

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the rotary handle has high sensitivity, the operator cannot perform low-speed rotary control under heavy load, which will cause certain safety hazards; When the slewing handle is set to the limit position, a high slewing speed cannot be obtained, which affects the working efficiency of the crawler crane

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

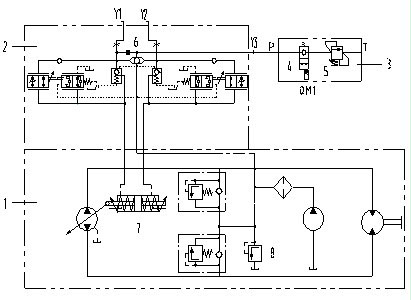

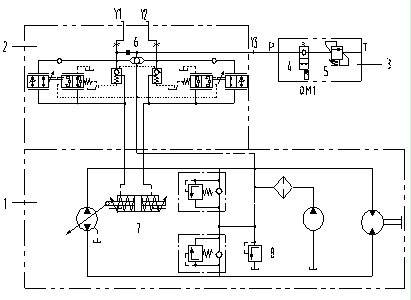

The invention provides a hydraulic system used for revolving jogging control on a crawler crane. The hydraulic system comprises a revolving pump motor loop, a revolving pump variable mechanism and a revolving slow valve, wherein the revolving slow valve comprises an electromagnetic directional valve and a pressure setting valve which are connected in series, one end of the revolving slow valve is connected with the input port of the revolving pump variable mechanism, and the other end of the revolving slow valve is connected with an oil tank. In the hydraulic system used for revolving jogging control on the crawler crane in the invention, a revolving slow valve is connected in parallel with the input port of the revolving pump variable mechanism to limit displacement of a revolving pump, thus revolving jogging control on the crawler crane can be effectively carried out, the structure is simple, the operation is simple, and the operation safety and high efficiency of the crawler crane can be effectively guaranteed.

Description

A Hydraulic System Used in Swing Micro-control of Crawler Crane technical field The invention relates to a hydraulic system, in particular to a hydraulic system for micro-motion control of the slewing of a crawler crane. Background technique All crawler cranes have a slewing function, that is, the upper car can rotate relative to the lower car. During the operation of the crawler crane, after lifting the heavy object on the vehicle and turning it at a certain angle, the heavy object is unloaded to the destination, and then rotated to complete a working cycle. Therefore, the slewing speed is an important indicator of crawler crane operation. Increasing the slewing speed can shorten the single operation time of the crawler crane and improve the operation efficiency. However, the higher the slewing speed of the crawler crane, the worse the safety and stability of its operation. Usually, the slewing speed of the crawler crane is realized by adjusting the angle of the slewi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B66C23/86B66C23/36

Inventor 陈元建

Owner SHANGHAI SANY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com