Wood plastic injection molding material and preparation method thereof

A wood and injection molding technology, applied in the field of wood injection molding materials and their preparation, can solve problems such as environmental pollution, human health damage, and difficulty in degradation, and achieve the effects of easy operation, simple preparation process and strong stability in the preparation process.

Inactive Publication Date: 2011-06-15

YOSHIYAMA PLASTIC

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, many injection molding products on the market are mainly formed of injection molding materials such as styrene, polycarbonate and polystyrene. On the one hand, these materials contain many harmful chemical components, which will cause harm to human health. Recycling, and it is difficult to degrade after being discarded, which will cause serious environmental pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

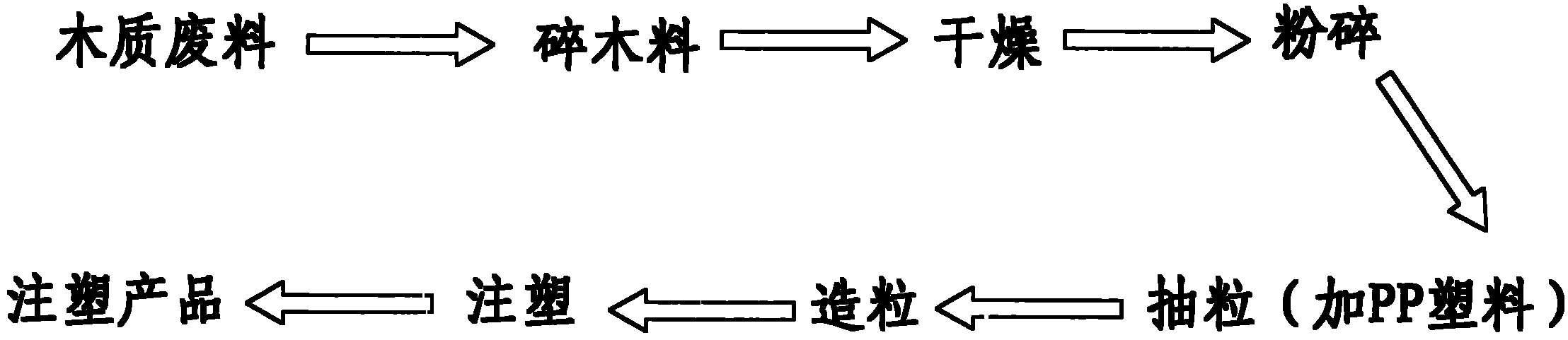

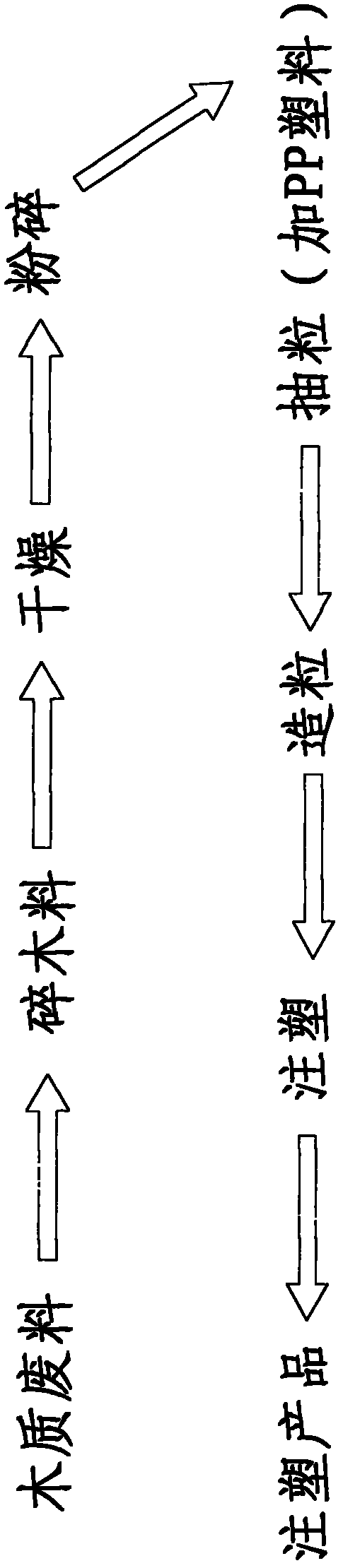

The invention relates to a wood plastic injection molding material and a preparation method thereof. The plastic injection material comprises 40 to 80 weight percent of wood particle material and 20 to 60 weight percent of polypropene (PP) plastic. The preparation method comprises: crushing and drying one or more than two wood waste materials to form a wood particle material; and fully mixing the wood particle material and the PP plastic according to the composition of the wood plastic injection molding material to obtain a target product. The wood plastic injection molding material, which can be recycled, is environmentally-friendly and safe to human bodies; the raw materials of the wood plastic injection molding material (such as trees, tree leaves, saw dust, and leftovers of industrial plates) are readily available, the consumption of plastic can be reduced greatly, the singleness of plastic injection molding material is changed, and the prepared product is very stable, free from contraction deformation and can be recycled; and the operation process is simple, easy to operate and low in cost. The wood plastic injection molding material can be widely used for making plastic products with wood appearance and has very breathable plant cultivating vessels, food and health-care package boxes and the like.

Description

Wood injection molding material and preparation method thereof technical field The invention relates to an injection molding material and a preparation process thereof, in particular to an injection molding material mainly formed of wood material and a preparation method thereof. The wood material is environmentally friendly, safe and recyclable. Background technique At present, many injection molding products on the market are mainly formed of injection molding materials such as styrene, polycarbonate and polystyrene. On the one hand, these materials contain many harmful chemical components, which will cause harm to human health. Recycling, and it is difficult to degrade after being discarded, will cause serious environmental pollution. Contents of the invention One of the objectives of the present invention is to propose a wood injection molding material, which uses wood waste as the main raw material, has the characteristics of environmental protection, no harm to th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L97/02C08L23/12

Inventor 李同裕

Owner YOSHIYAMA PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com