Multilayered evaporation/distillation pot type liquid purification device

A technology of liquid purification device and distillation tank, which is applied in the installation/connection of lubricant purification device, lubricated parts, pressure lubricant, etc., to achieve the effects of easy installation and maintenance, enhanced work efficiency, and maximized purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

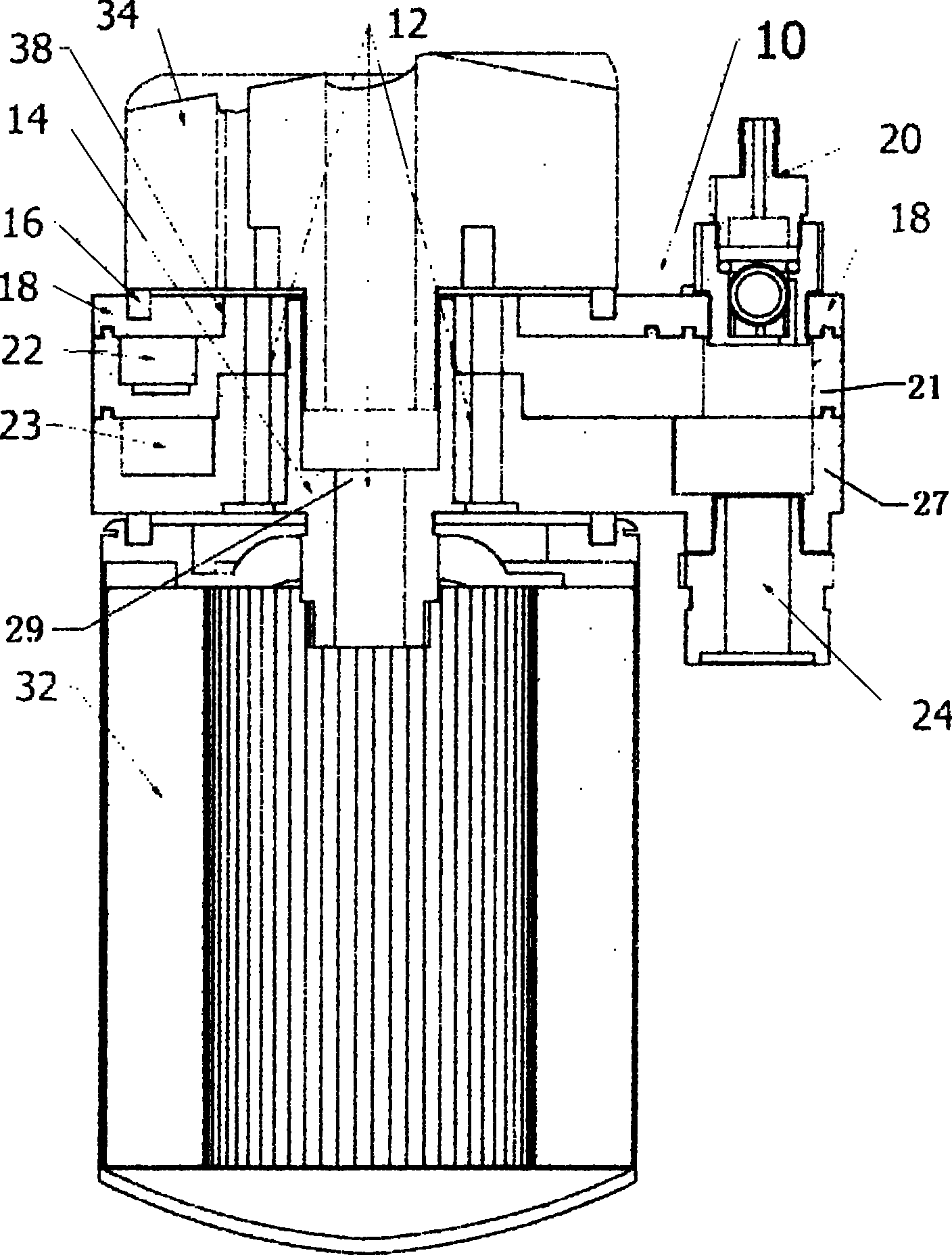

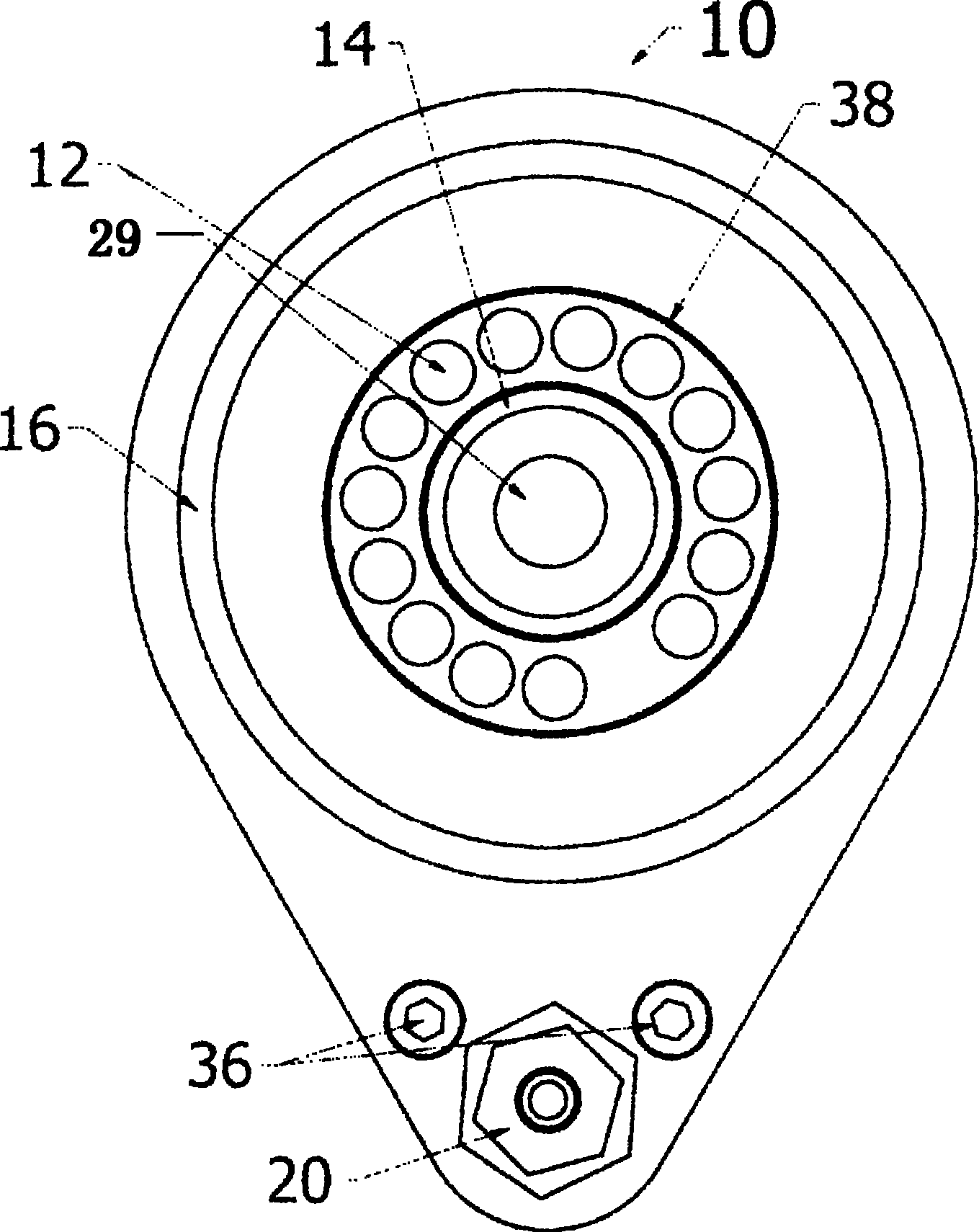

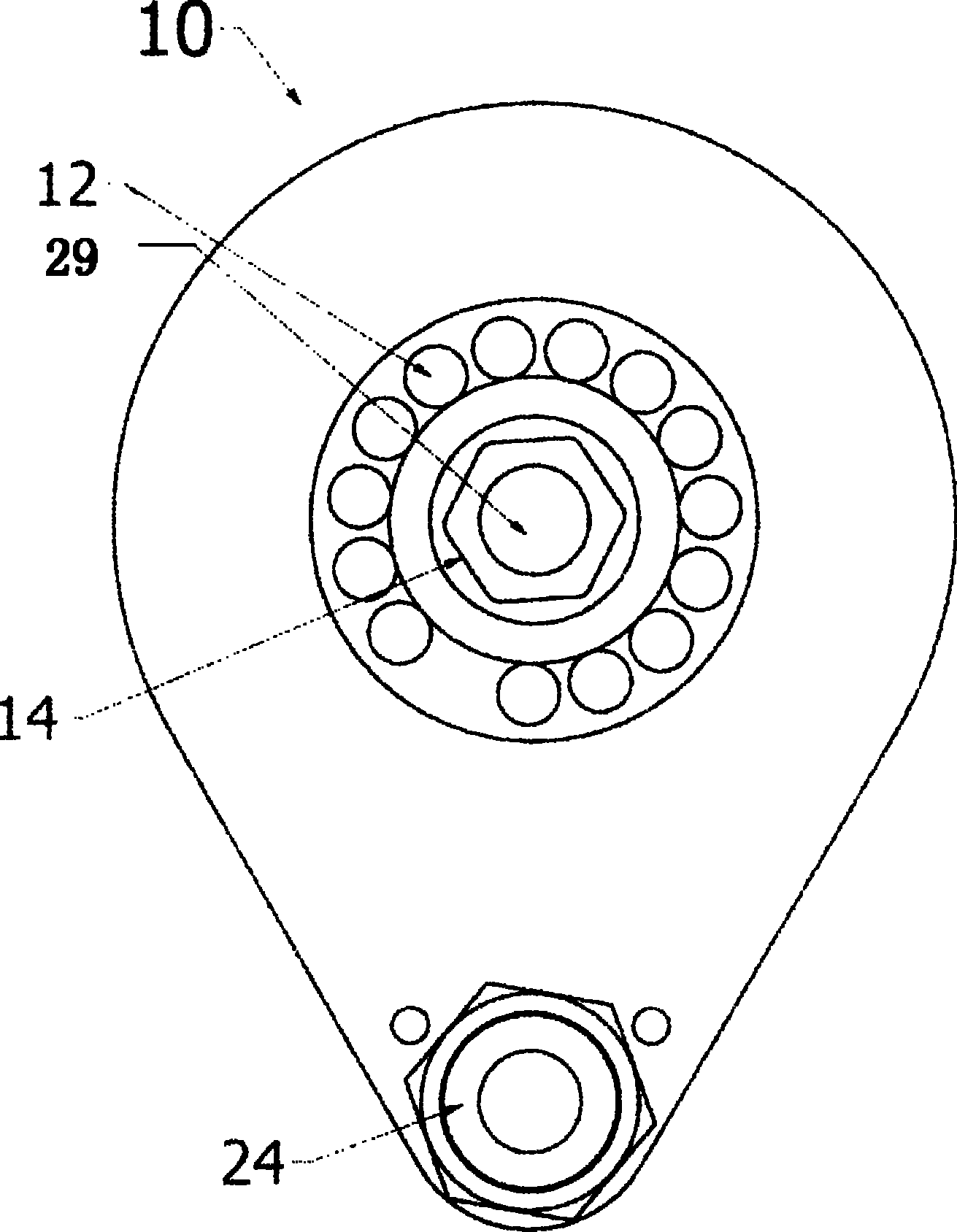

[0024] A multi-layer evaporation / distillation tank type liquid purification device 10 includes a plurality of stacked and fixed tank bodies. In this embodiment, it is composed of two tank bodies, the upper tank body 21 and the lower tank body 27, but of course it can also be more than two tank bodies. In the radial direction of the upper tank body, an annular groove-shaped evaporation chamber 22 partitioned from the end to the end is formed, and an annular groove-shaped evaporation chamber 23 partitioned from the end to the end is also formed on the radial direction of the lower tank body. The upper tank body and the lower tank body are axially formed with a central hole 29 and a plurality of return holes 12 corresponding i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com