Method and device for seismic strengthening of shape memory alloy pipe networks

A technology of memory alloy and reinforcement device, which is applied in the direction of flange connection, pipe/pipe joint/fitting, adjustable connection, etc. It can solve the problems of brittle failure of connection parts, leakage, excessive deformation of pipe joints, etc., and reduce earthquakes The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

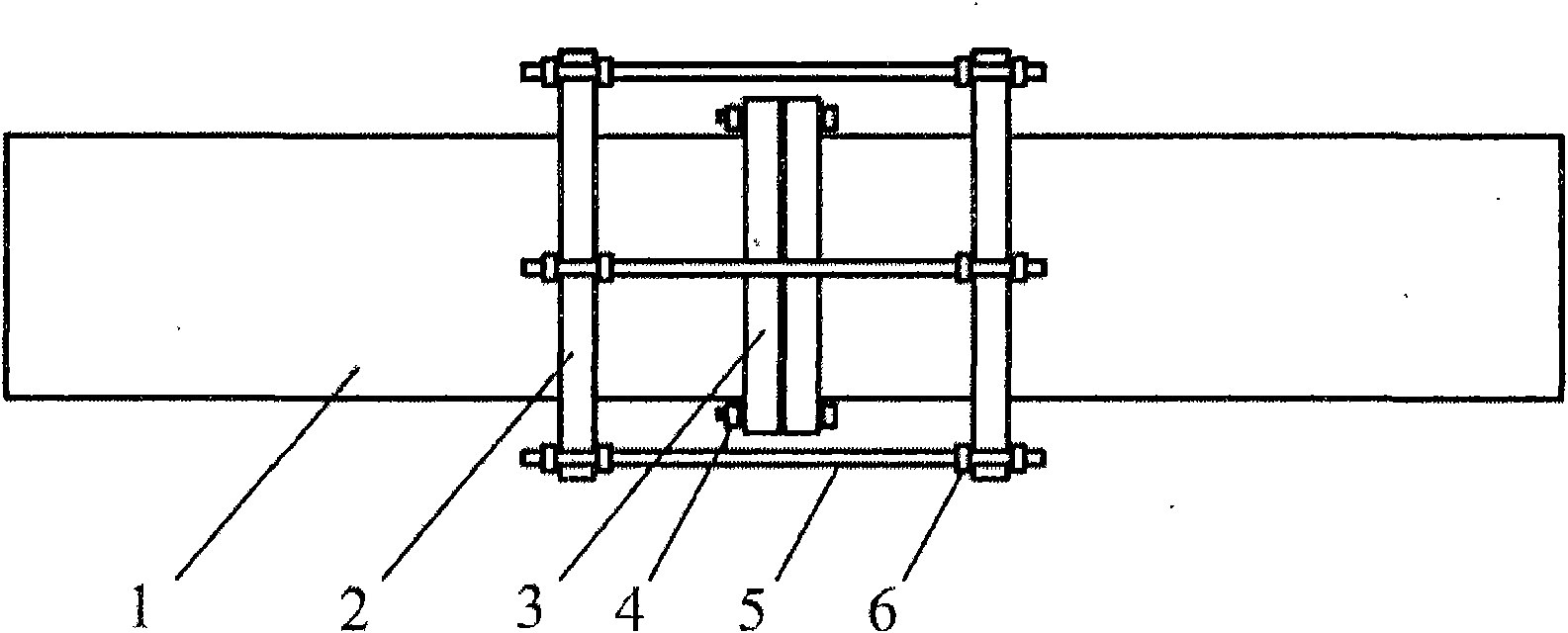

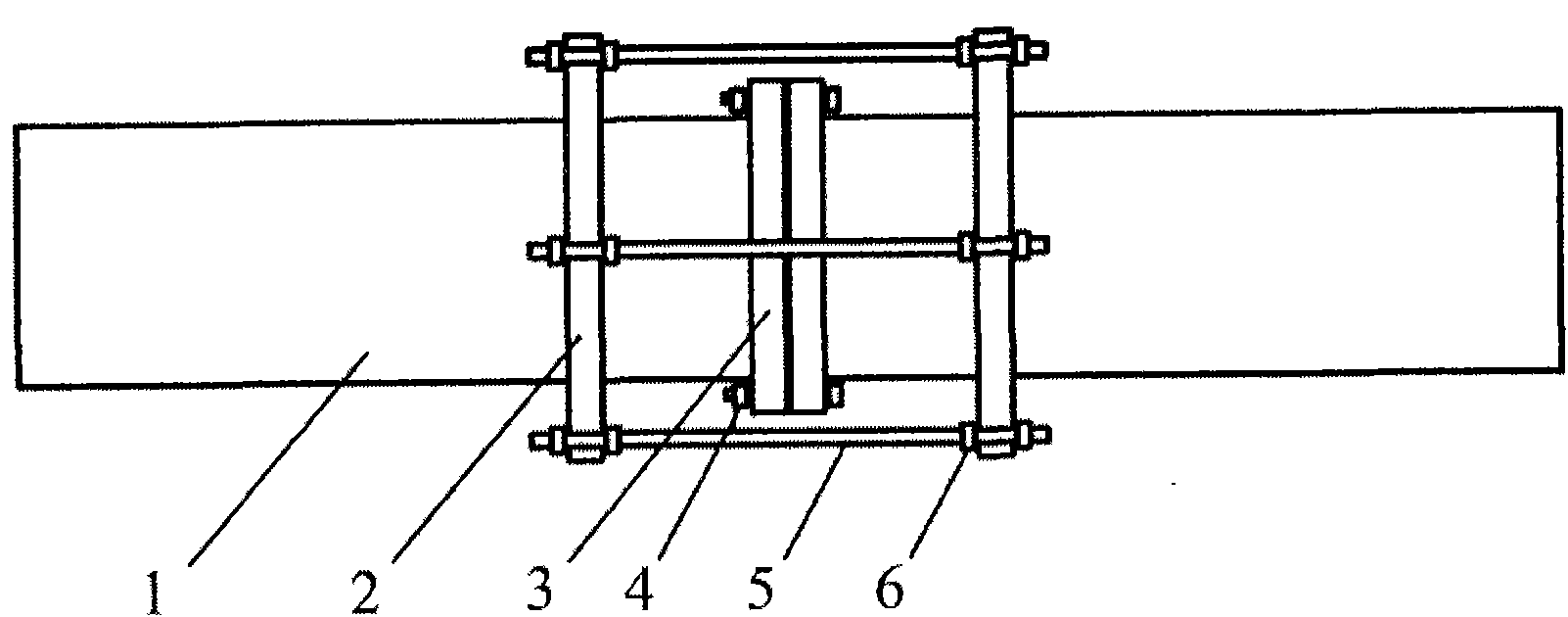

[0013] Example 1: Combining figure 1 , the device that a kind of shape memory alloy pipeline network anti-seismic strengthening method of the present invention adopts is by pipeline (1), fixed connector flange (2), pipeline flange (3), pipeline connection bolt (4), shape memory alloy rod (5) and the shape memory alloy rod connecting bolt (6), the pipe (1) is connected to the pipe flange (3), the pipe flange (3) is connected to the pipe connecting bolt (4), and the fixed connector flange (2) Located on both sides of the pipeline flange (3), the fixed connector flange (2) is connected to the shape memory alloy rod (5), and the shape memory alloy rod (5) is connected to the shape memory alloy rod connecting bolt (6).

Embodiment 2

[0014] Example 2: Combining figure 1 , the invention comprises a fixed connection piece at both ends of a pipeline flange and a thin NiTi shape memory alloy rod in an austenite state. The diameter and quantity of the shape memory alloy rods are designed according to the size of the pipeline and the anti-seismic fortification target. The fixed connecting piece is welded and fixed to the pipeline, holes are symmetrically opened on the connecting piece according to the number of shape memory alloy rods, and the shape memory alloy rod and the connecting piece are bolted.

[0015] The invention is mainly aimed at the seismic strengthening of pipelines, and its main idea is that the large deformation and self-resetting ability of the superelastic properties of shape memory alloys can better protect pipelines from damage during earthquake damage, so it is extremely stable during the entire earthquake process. Greatly improving the possibility of normal operation of the lifeline syst...

Embodiment 3

[0016] Embodiment 3: The seismic strengthening method of the shape memory alloy pipe network of the present invention, the technical solution is realized through the following three steps:

[0017] The first step: select a Q235 steel plate not less than 10mm thick, and make a shape memory alloy rod to fix the connecting piece. The inner diameter of the connector is equal to the outer diameter of the pipe, and the outer diameter is not less than the inner diameter plus 8cm. According to the quantity of the shape-memory rods, holes are opened symmetrically along the periphery of the outer diameter of the connector, and the diameter of the holes is equal to the diameter of the shape-memory rods.

[0018] Step 2: Select thin austenitic NiTi shape memory alloy rods with a diameter range of 10-30 mm, and form threads at both ends of the shape memory alloy rods by machining.

[0019] Step 3: Weld and fix the fixed connecting piece with the pipe wall, insert the shape memory alloy ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com