Method for establishing high-power light emitting diode (LED) illuminating lamp and standard interface LED lamp cap

A technology of LED lighting and LED lamp holders, which is applied to components of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc., can solve problems such as multiple product specifications, maintenance delays, and fault expansion, and achieve interface and Effects of interchangeability, simplified design and production, and simplified thermal design

Inactive Publication Date: 2011-06-15

GUIZHOU GUANGPUSEN PHOTOELECTRIC

View PDF3 Cites 47 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This has brought a series of fatal problems such as high manufacturing cost, inconvenient use, and difficult maintenance to LED lighting fixtures.

First of all, it is impossible to achieve national and even global unified and standardized production in manufacturing, resulting in many product specifications, few batches, and high prices; secondly, the products of each company are various and not compatible with each other. One LED lighting user may involve several or even several companies. Products from ten manufacturers; when the third product fails, it is necessary to remove the LED optical module, drive power supply, and lamp housing as a whole for maintenance, which is very easy to cause fault expansion, maintenance delays, and high maintenance costs.

These defects have greatly restricted the promotion and use of high-power LEDs, and are flaws in the promotion of high-power LED lighting products.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

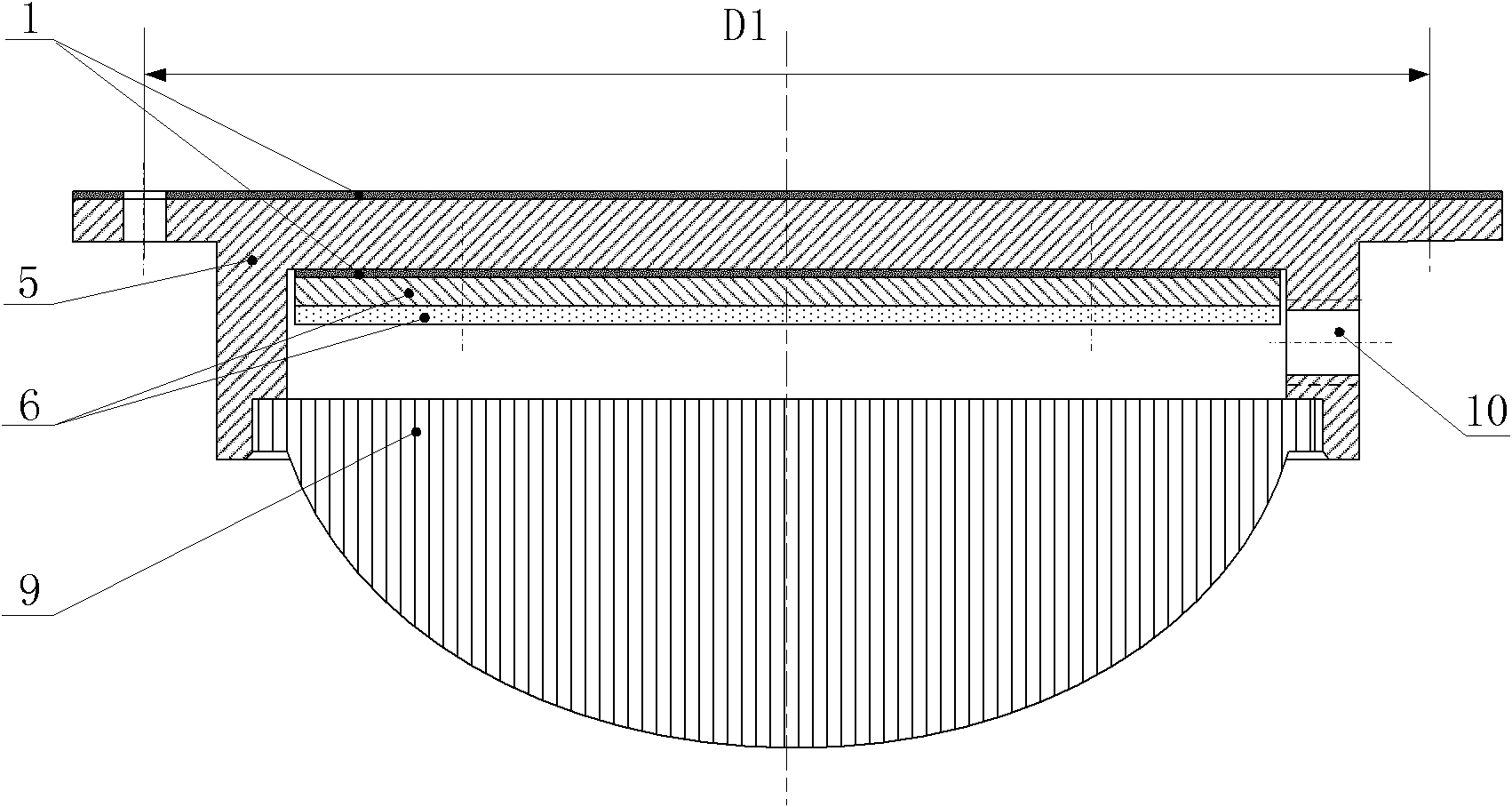

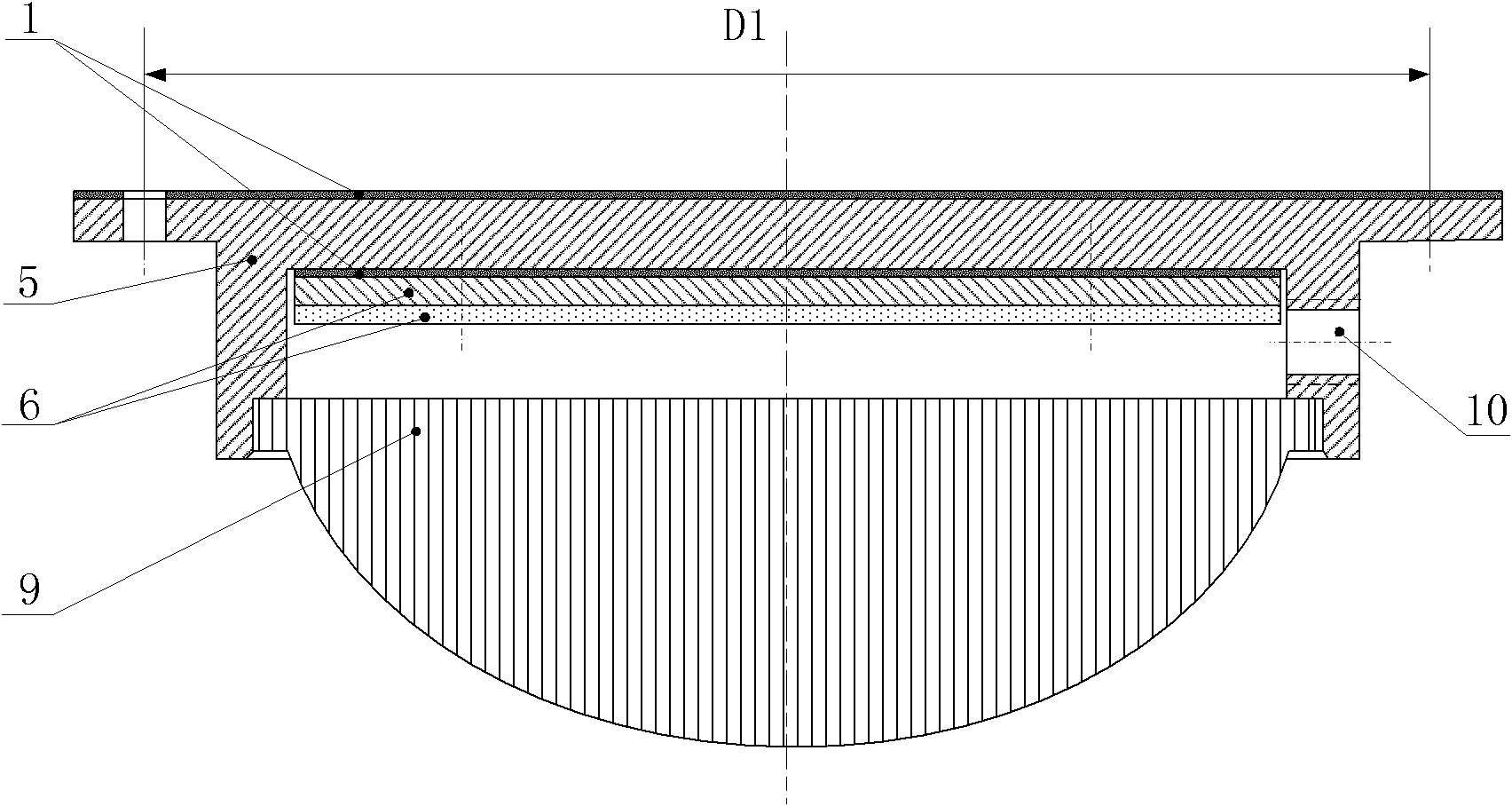

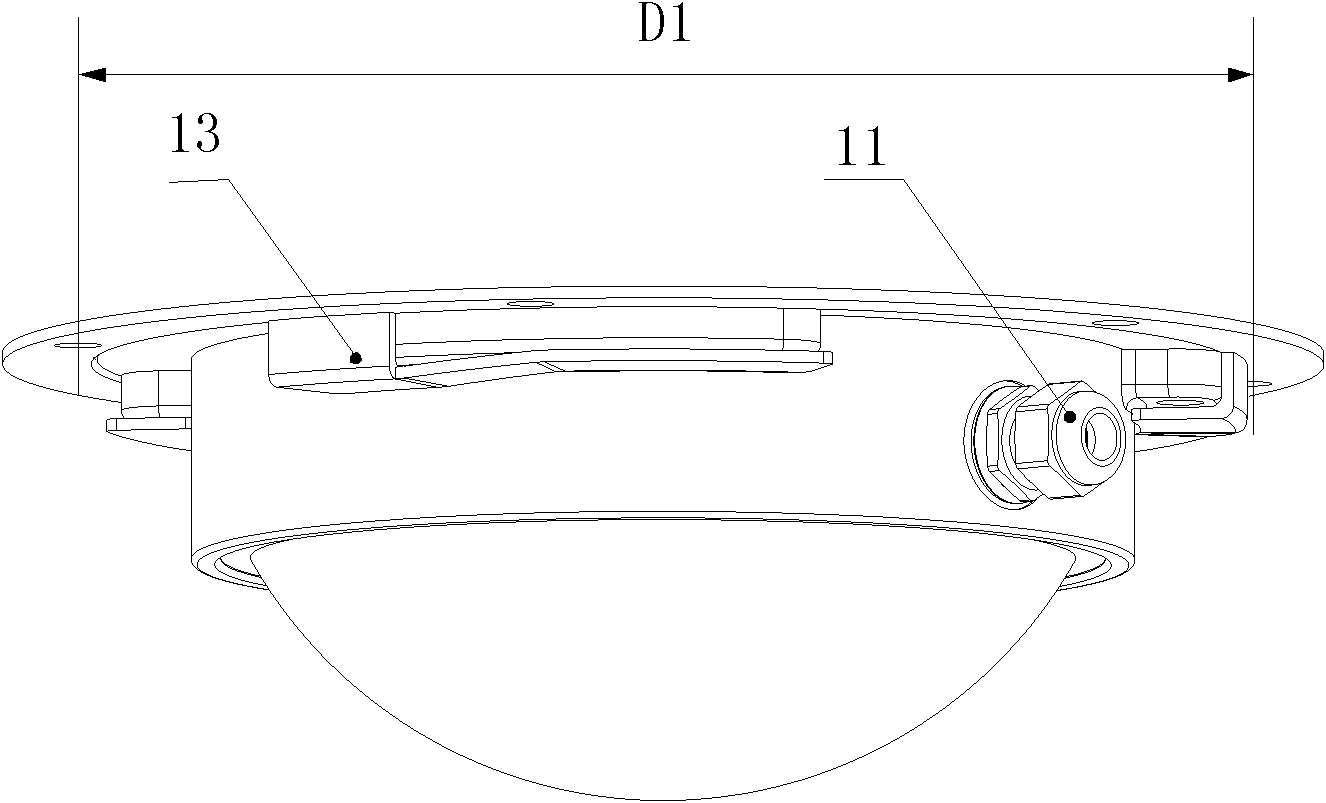

The invention discloses a method for establishing a high-power light emitting diode (LED) illuminating lamp and a standard interface LED lamp cap. The method is characterized in that: the high-power LED illuminating lamp is formed by assembling one or more standard interface LED lamp caps on which LED light modules and independent driving power sources are integrated on a lamp holder. By the method, the production processes of the LED illuminating lamp can be greatly reduced, the batch production can be improved, and the industrialization of LED energy-saving illuminating products is facilitated.

Description

Method for building a high-power LED lighting fixture and a standard interface LED lamp holder technical field The invention relates to a method for building a high-power LED lighting fixture and a standard interface LED lamp holder, belonging to the technical field of LED lighting. Background technique LED light-emitting diode lighting has the advantages of high luminous efficiency, easy control of lighting direction and brightness, etc. The luminous efficiency of current LED lighting can exceed 70LM / W, which is more energy-saving than traditional energy-saving lamps. Theoretically, the luminous efficiency of green LEDs can be as high as 683LM / W; the theoretical efficiency of white LEDs can also reach 182.45LM / W, so there is huge room for improving LED lighting efficiency. In the current design of high-power LED lighting lamps, especially high-power LED lamps such as street lamps, due to heat dissipation, when assembling a high-power LED lamp, the integrated design of LE...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F21S2/00F21V19/00F21V29/00F21V5/04F21V17/10F21V17/12F21Y101/02F21K9/232F21K9/235F21K9/69F21V29/50F21V29/502F21Y115/10

Inventor 张继强张哲源

Owner GUIZHOU GUANGPUSEN PHOTOELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com