Method for establishing three-dimensional coordinate system of large test equipment

A large-scale experiment, coordinate system technology, applied in the direction of measuring devices, instruments, measuring instrument components, etc., to achieve the effects of good stability, high precision, and simple implementation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

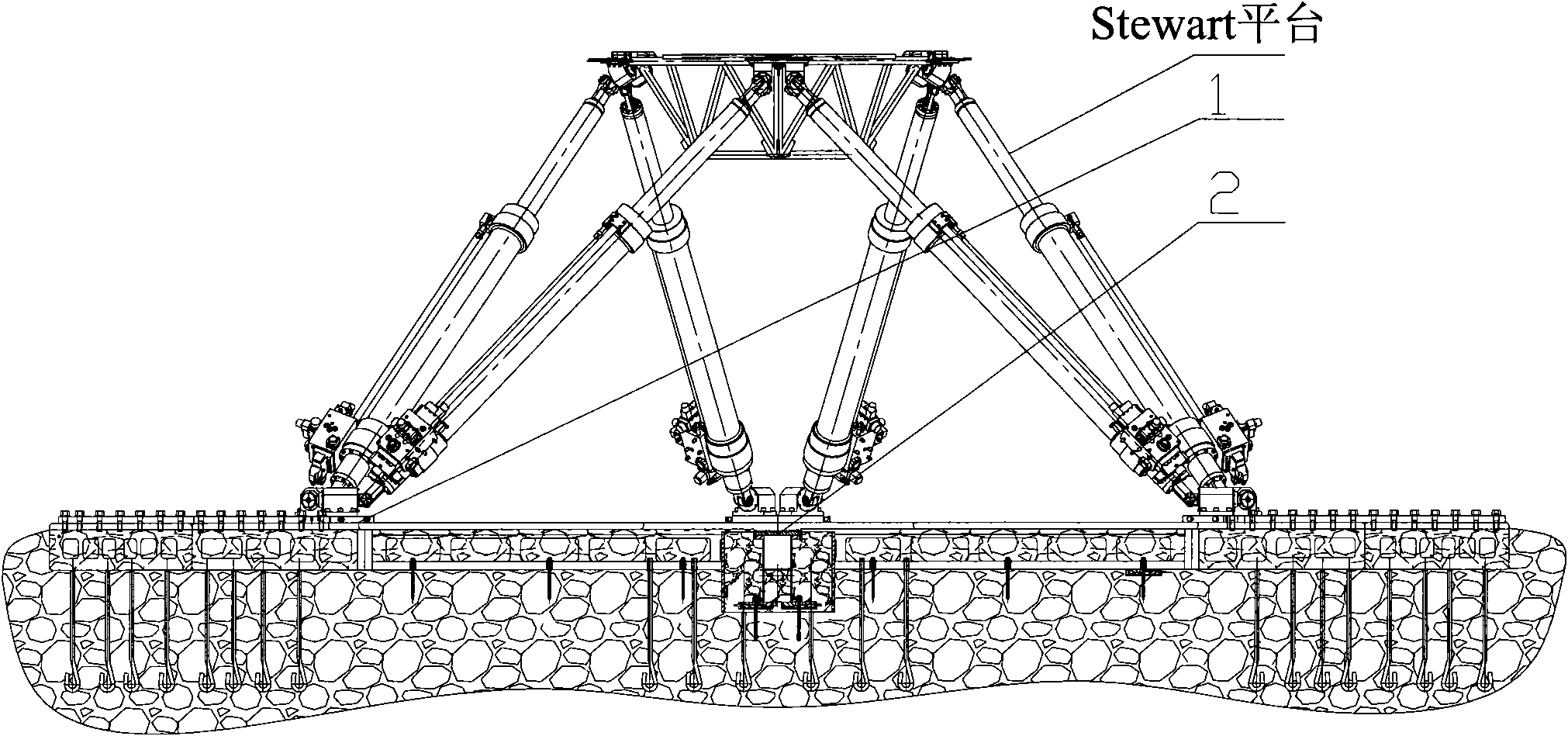

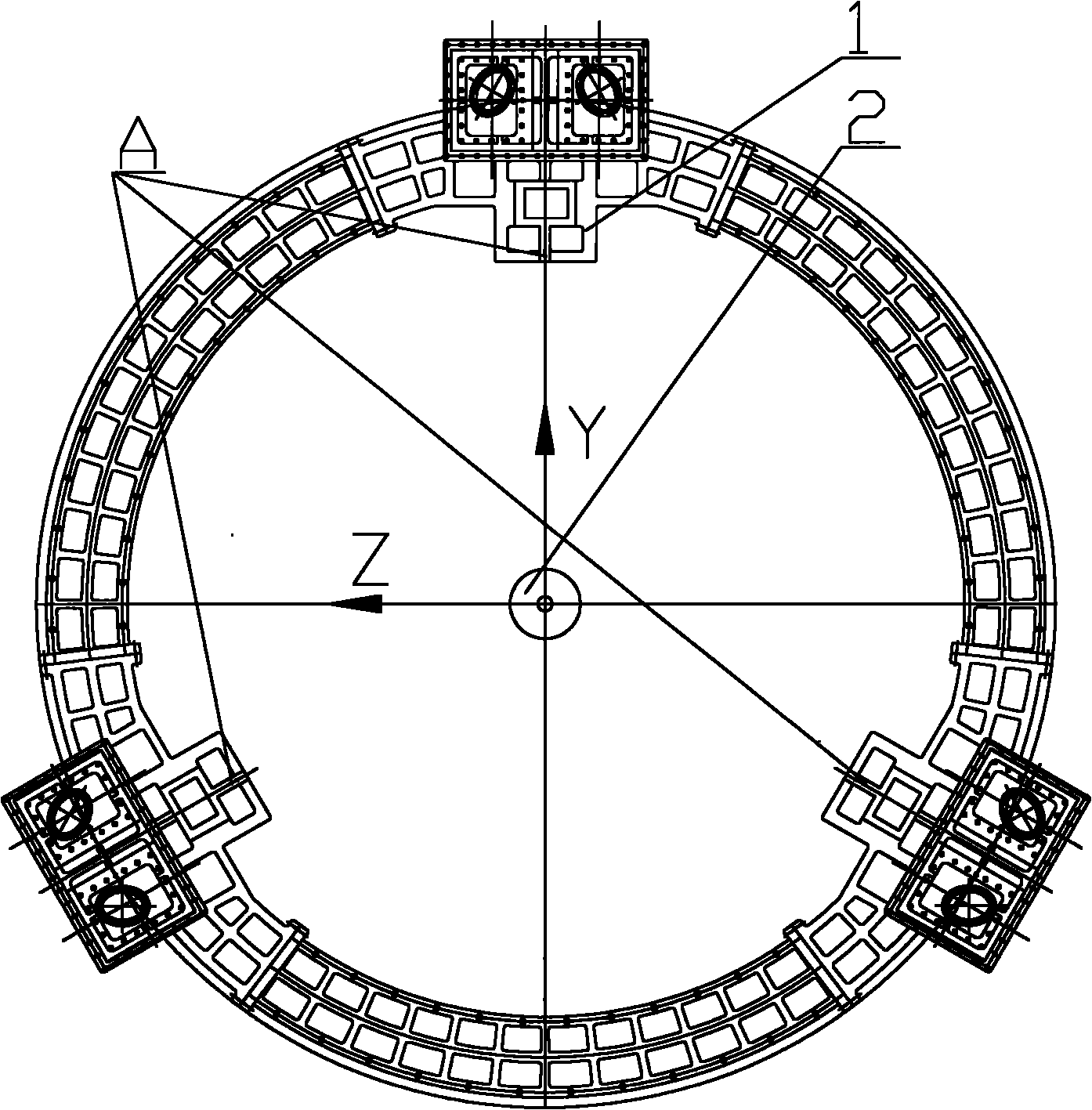

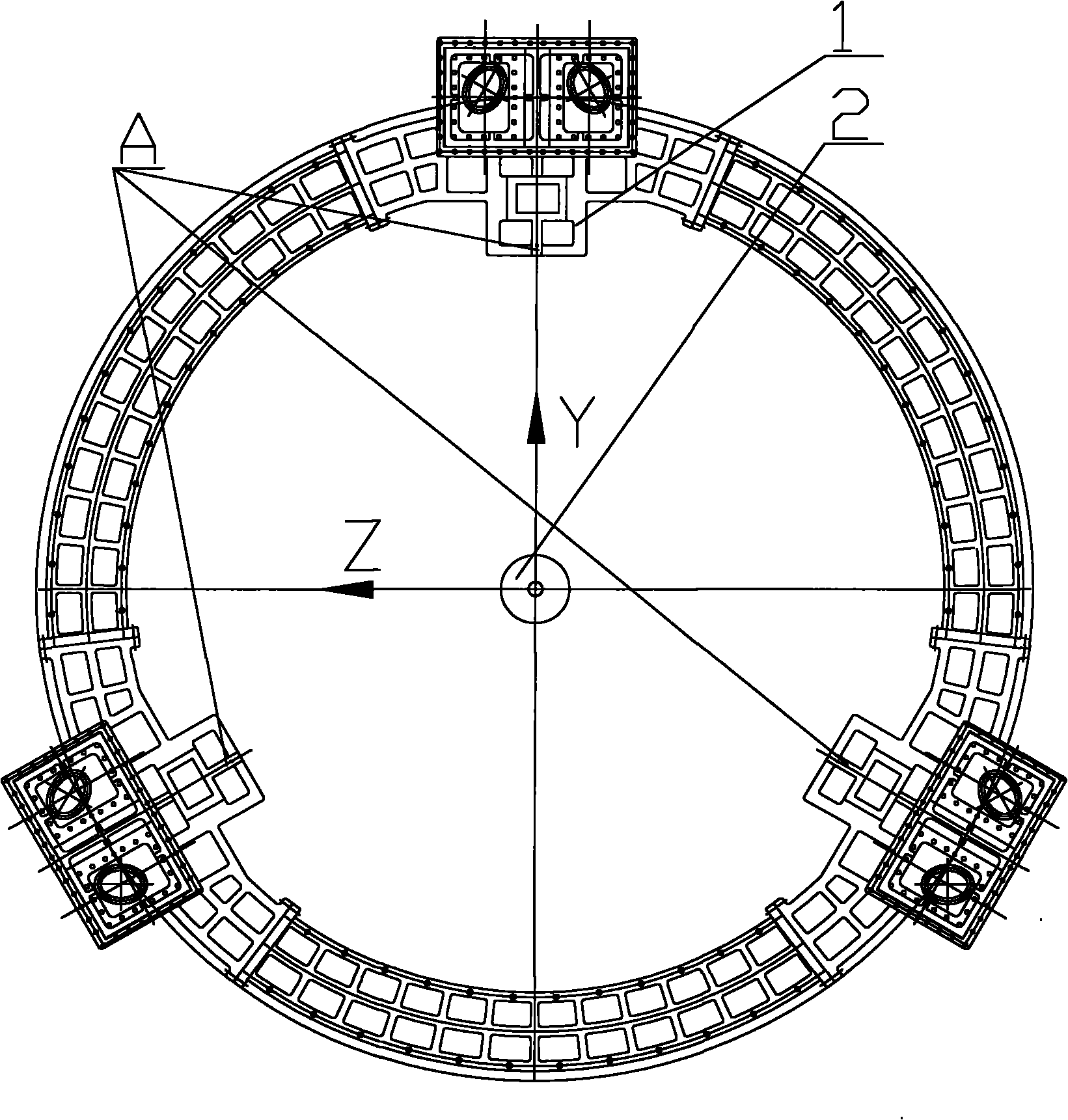

[0016] The accompanying drawing is a coordinate system structure diagram of a certain large-scale test equipment. The present invention uses the six-degree-of-freedom Stewart platform with a lower hinge distribution circle of 7.4 meters as an example to illustrate the implementation steps of the present invention.

[0017] As shown in the drawings, the six-degree-of-freedom Stewart platform coordinate system includes: three datum seats 1 at the trisection of the annular base; and a coordinate datum 2 at the center of the annular base.

[0018] A method for setting up a three-dimensional coordinate system of large-scale test equipment in the present invention comprises the following steps:

[0019] (1) Set the datum plane A at the inner center positions of the three datum seats 1 of the annular base; set the measuring datum hole at the central position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com