Temperature-measuring element shock resisting device and installation method thereof

A technology of a temperature measuring element and an installation method, which is applied to the installation of the device and the field of impact-resistant casing, can solve the problems of damage to the temperature measuring element, affecting the normal progress of construction and production, etc., and achieves extended service life, simple structure, and easy installation. Effect

Inactive Publication Date: 2011-06-15

CHINA FIRST METALLURGICAL GROUP

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Especially the temperature measuring element on the process pipeline, when the medium pressure of the pipeline is high and the flow rate is large, it will be subject to a greater impact, especially when the medium produces water hammer or air hammer effect due to pulsation, it will directly cause damage to the temperature measuring element , affecting the normal progress of construction and production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

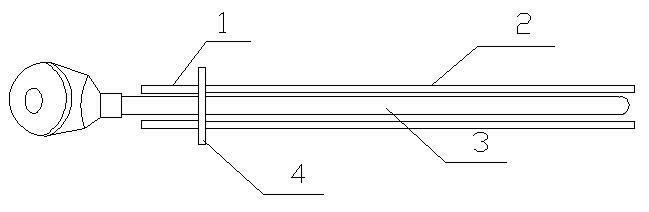

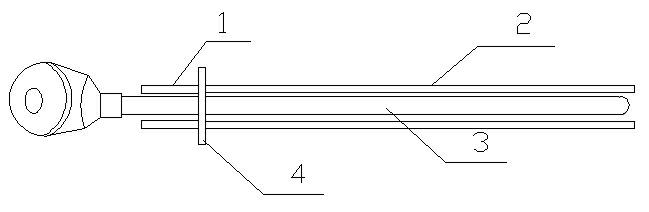

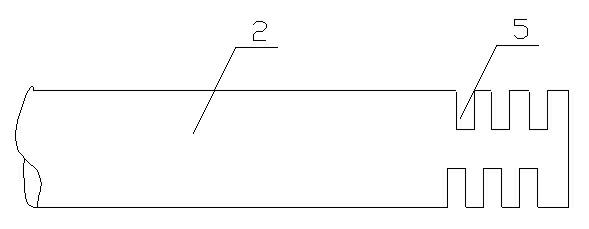

The invention relates to a temperature-measuring element shock resisting device and also relates to an installation method of the device. The temperature-measuring element shock resisting device comprises a temperature-measuring element, an installation component and a protective sleeve, wherein the installation component is fixedly installed on the wall of a process pipe, the protective sleeve is connected with the protective sleeve, the sum of the lengths of the protective sleeve and the installation component is larger than the length of the temperature-measuring element inside the process line, and the protective sleeve has the same inner diameter as the installation component. The temperature-measuring element shock resisting device disclosed by the invention is simple in structure, convenient in installation and simpler in operation. The temperature-measuring element shock resisting device realizes the shock resisting protection for the temperature-measuring element, prolongs the service life of the temperature-measuring element and lowers the workload and cost for maintaining instruments. Furthermore, notches or openings are formed at the end parts of the protective sleeve, which increases the flowability of the medium, ensures the superior contact between the temperature-measuring element and the medium and guarantees the timeliness and the accuracy of temperature measurement.

Description

Anti-shock device for temperature measuring element and its installation method technical field The invention relates to an anti-shock device for temperature measuring elements, in particular to an anti-shock casing for temperature measuring elements such as thermocouples and thermal resistors; the invention also relates to an installation method of the device. Background technique Industrial temperature measuring components mainly include thermocouples and thermal resistances, whose function is to convert temperature signals into electrical signals for temperature detection and control. Temperature measuring elements are widely used in blast furnaces, hot blast stoves, heating furnaces, sintering, oxygen production and other systems. The installation quality of temperature measuring components directly affects the stability and control accuracy of the control system. Especially the temperature measuring element on the process pipeline, when the medium pressure of the pip...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01K1/08G01K1/14G01K7/02G01K7/16

Inventor 李德家张晓峰郑运洪季华峰李伟李和平

Owner CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com