Vibration measuring method of engine speed by applying four-point energy centrobaric correction method

A technology for measuring engine speed and vibration, applied to equipment with unique mechanical means, etc., can solve problems such as the inability to measure the engine speed and the unpredictable number of engine cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

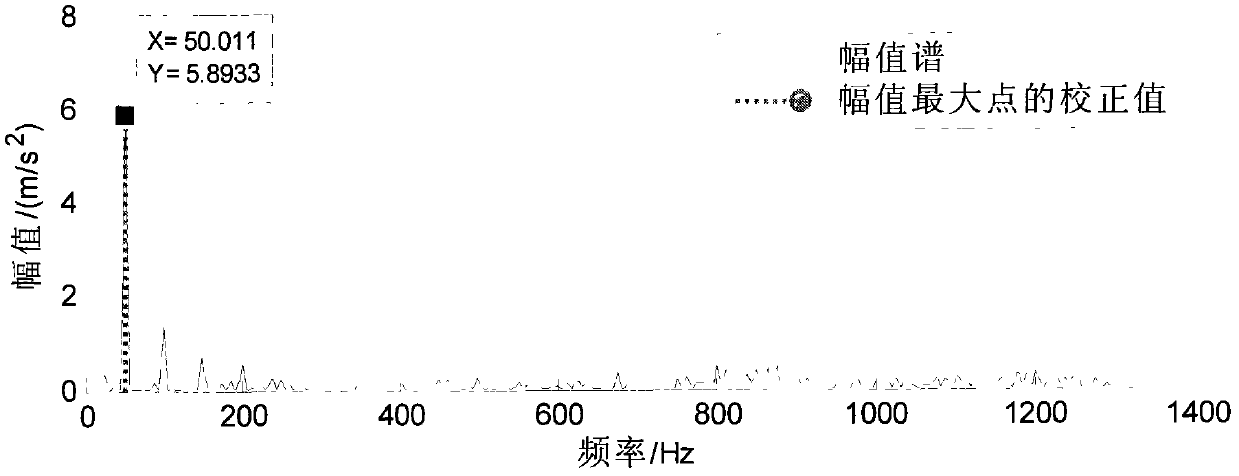

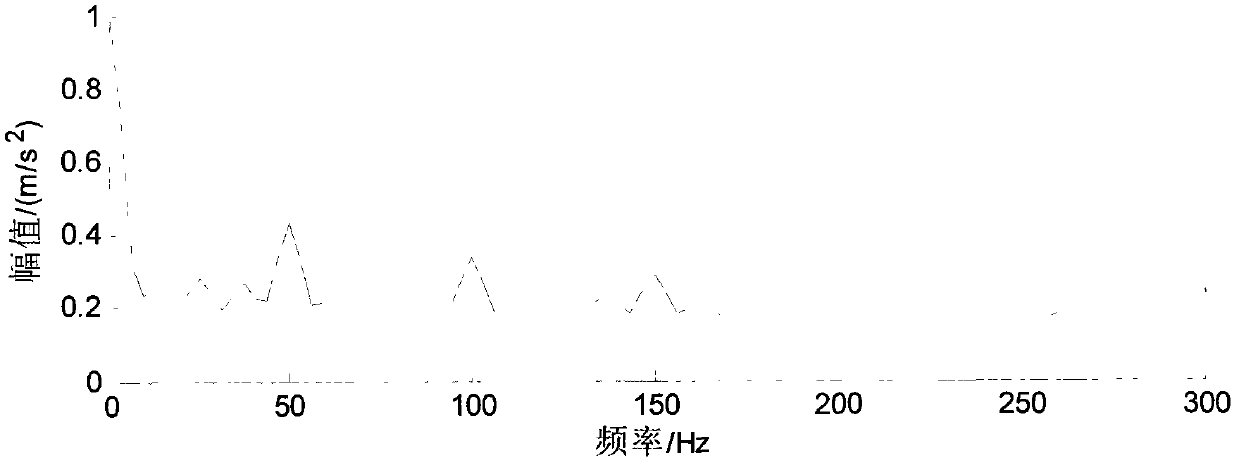

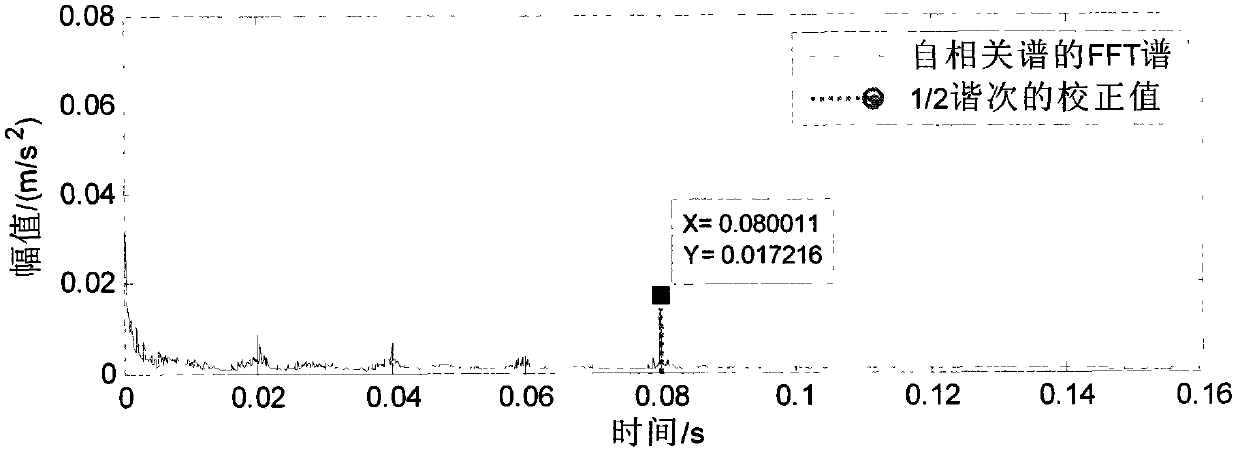

[0047] Embodiment 1——Engine bench test

[0048] The verification experiment of speed identification was carried out on the engine bench, and the speed measured by this test method was compared with the results measured by the German AVL measurement and control system.

[0049] (1) Establishment of the coordinate system: the engine under test is a four-stroke EFI engine with an unknown number of cylinders, and the coordinate system O-XYZ is established, with the connection point between the engine and the transmission as the origin O, the positive direction of the Y axis points to the front end of the crankshaft, and the positive direction of the Z axis Vertically upward, according to the right-hand rule to determine the positive direction of the X-axis;

[0050] (2) Install the sensor: Install the PCB acceleration sensor on the flat surface of the engine block, and the test direction is Z direction; the sensor is connected to the Millerbeum (BBM) MKII signal collector, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com