Calibration system of wind direction sensor

A technology of wind direction sensor and calibration system, which is applied to the testing/calibration of instruments, speed/acceleration/shock measuring equipment, and measuring devices, etc., which can solve the problems of time-consuming, prone to false readings, and low calibration efficiency, so as to improve Calibration speed, guaranteed calibration accuracy, practical and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

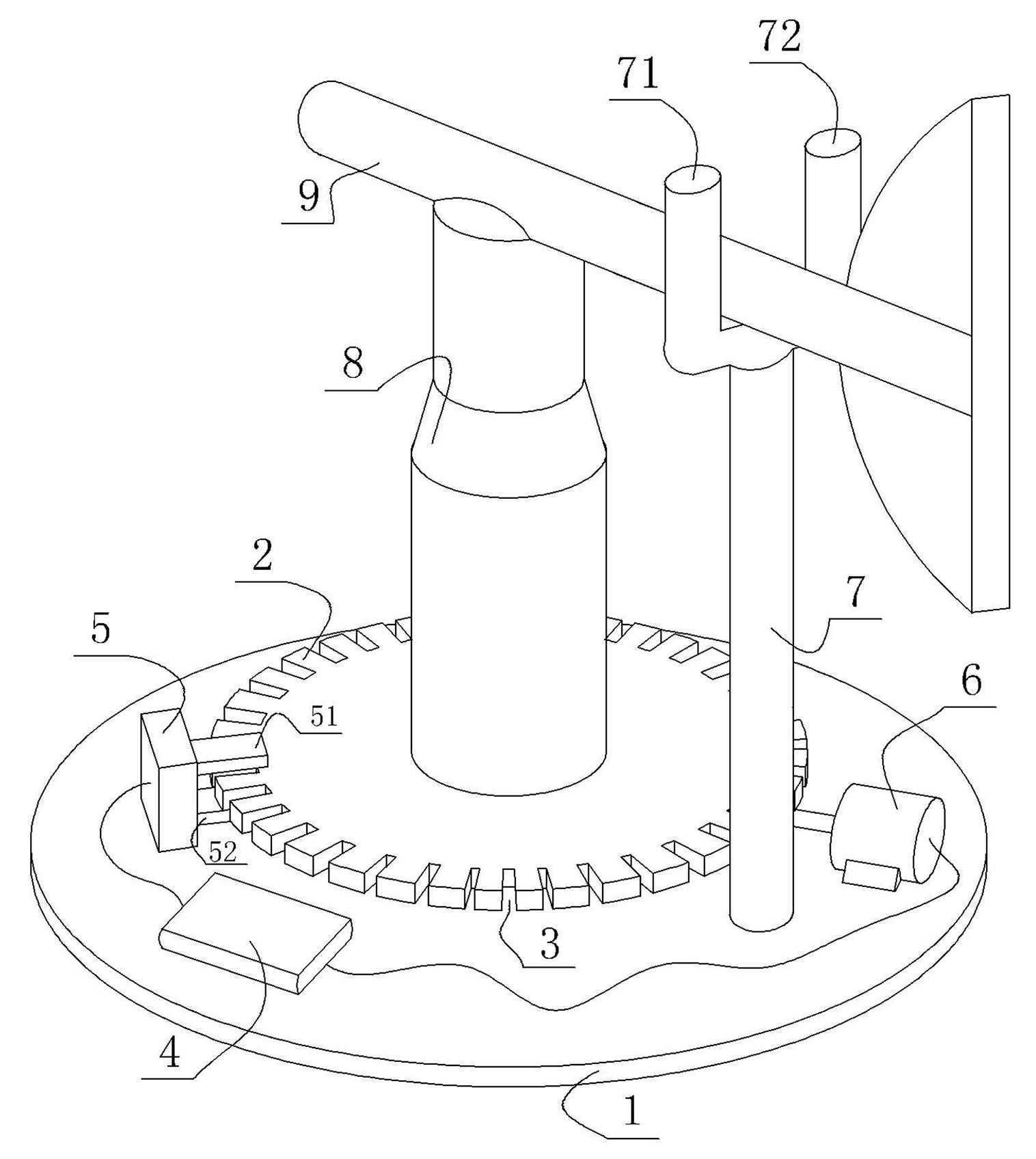

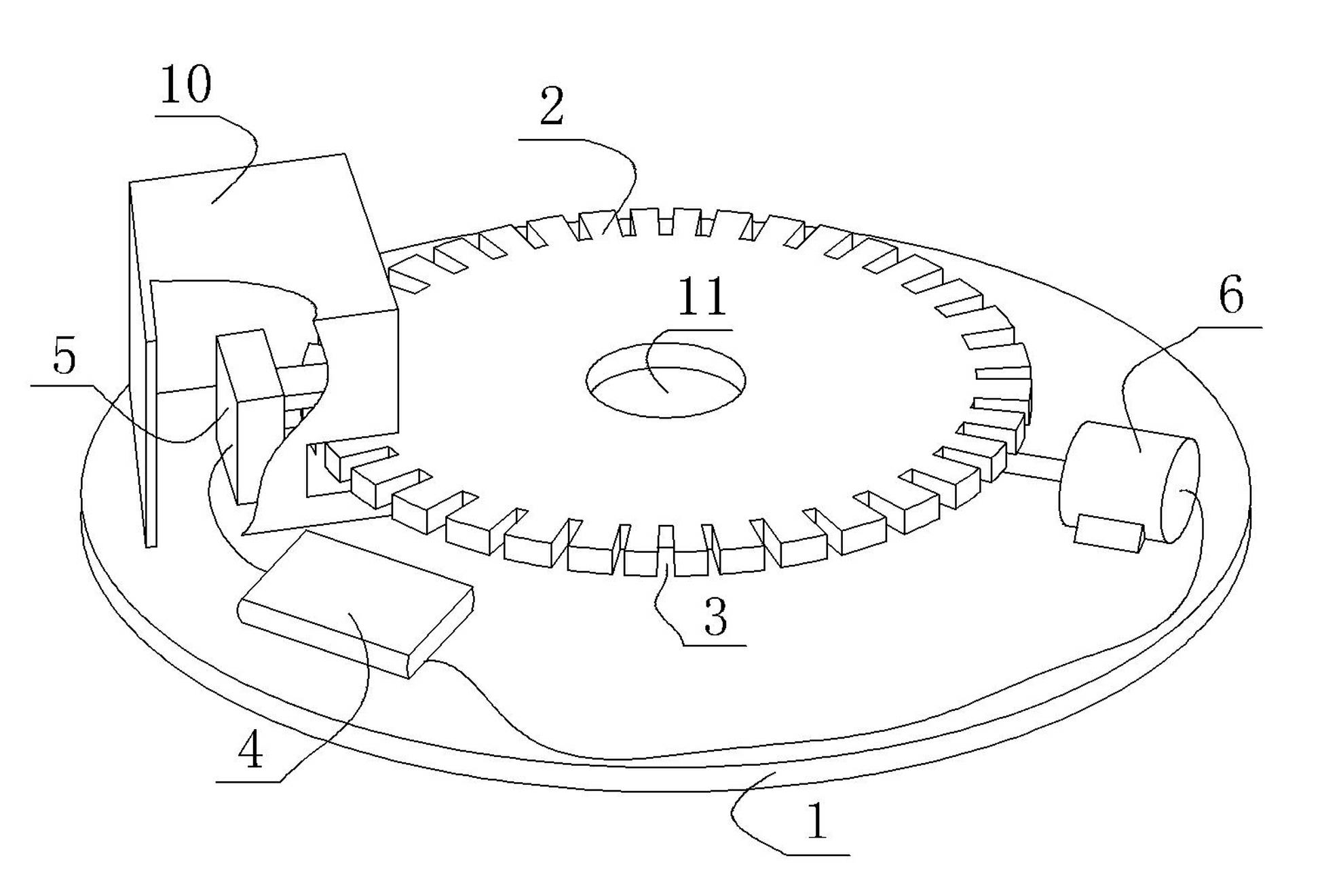

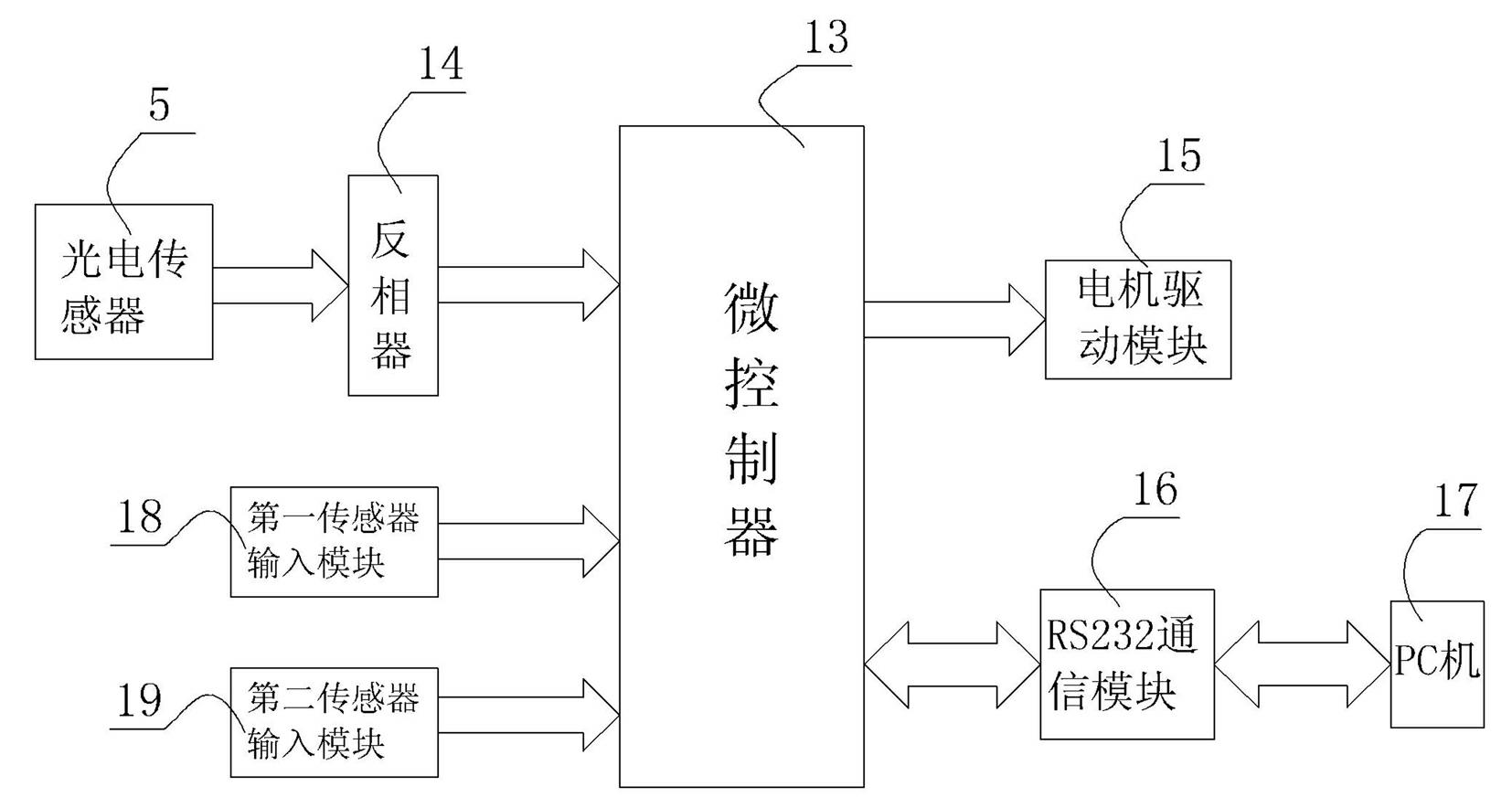

[0024] Such as figure 1 and figure 2 As shown, the practical state diagram and structure diagram of the present invention are respectively provided, which include a base 1, a rotating disk 2, a control circuit 4, a photoelectric sensor 5, a driving motor 6, a U-shaped bracket 7, and a wind direction sensor 8. The shown base 1 mainly plays the role of fixing and supporting. The rotating disk 2 is arranged on the base 1 and can rotate. In order to ensure that the rotating disk 2 can rotate freely, the rotating disk 2 and the base 1 are connected through bearings, so that The disc 2 can freely rotate around an axis perpendicular to the base 1, which ensures the detection accuracy of the system. The center position of the rotating disk 2 is provided with a fixing hole 11 matching with the wind direction sensor 8, the fixing hole 11 can realize the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com