Lithium ion battery cover cap

A lithium-ion battery and cap technology, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as inability to effectively ensure the safe use of batteries, increase in internal resistance of lithium-ion batteries, and harm to users of electronic products. Reduce battery internal resistance, precise and stable rupture critical pressure value, easy rupture effect

Inactive Publication Date: 2011-06-15

江门市朗达集团有限公司

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. The existing lithium battery cap usually has an indentation on the bottom cover, and the indentation breaks when the internal pressure of the lithium battery reaches a dangerous value to achieve the purpose of pressure relief and safety, but the existing structure cannot guarantee pressure. The mark breaks when the pressure reaches the design value, and its error range is large, which cannot effectively guarantee the safe use of the battery;

2. Because the top cover and the bottom cover are sealed and fixed by sealing rings, the contact resistance between the top cover and the bottom cover will increase during long-term storage or use, resulting in an increase in the internal resistance of the entire lithium-ion battery , thus affecting its output voltage, and even unable to charge and discharge normally;

3. The sealing ring is usually made of non-metallic materials such as plastics. After long-term storage or use, due to the decline in sealing ability, liquid leakage will occur. This will not only damage the battery itself, but also the leaked battery liquid has a strong Corrosive, harmful to electronic products and users

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

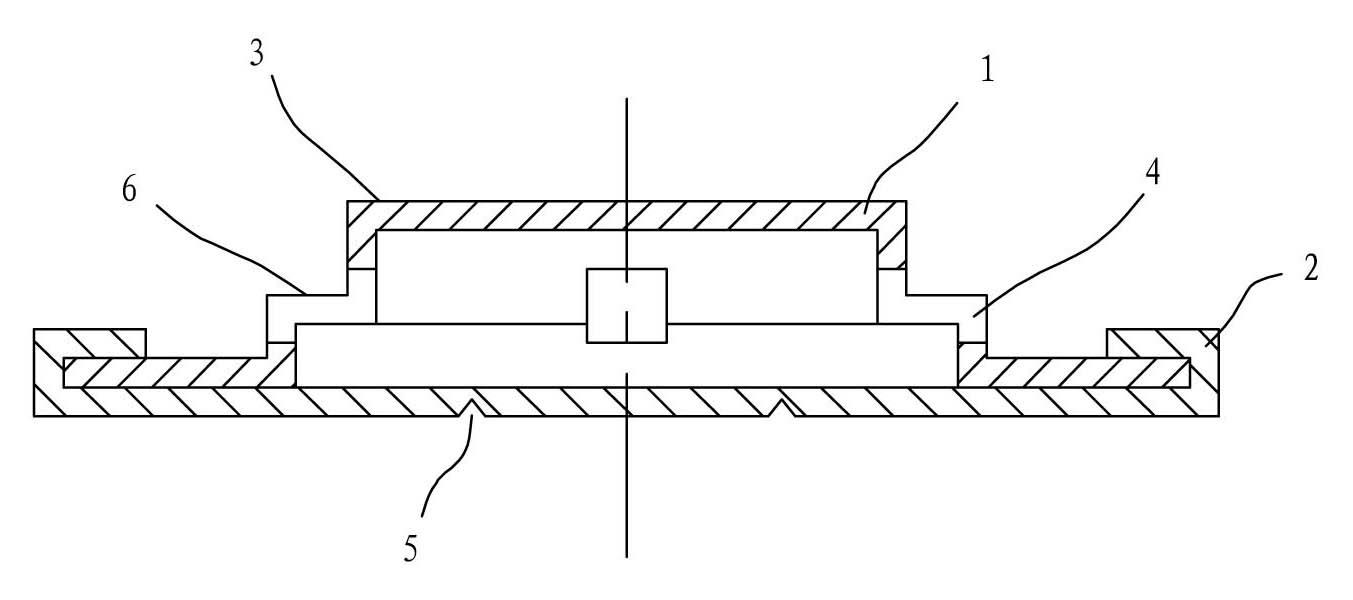

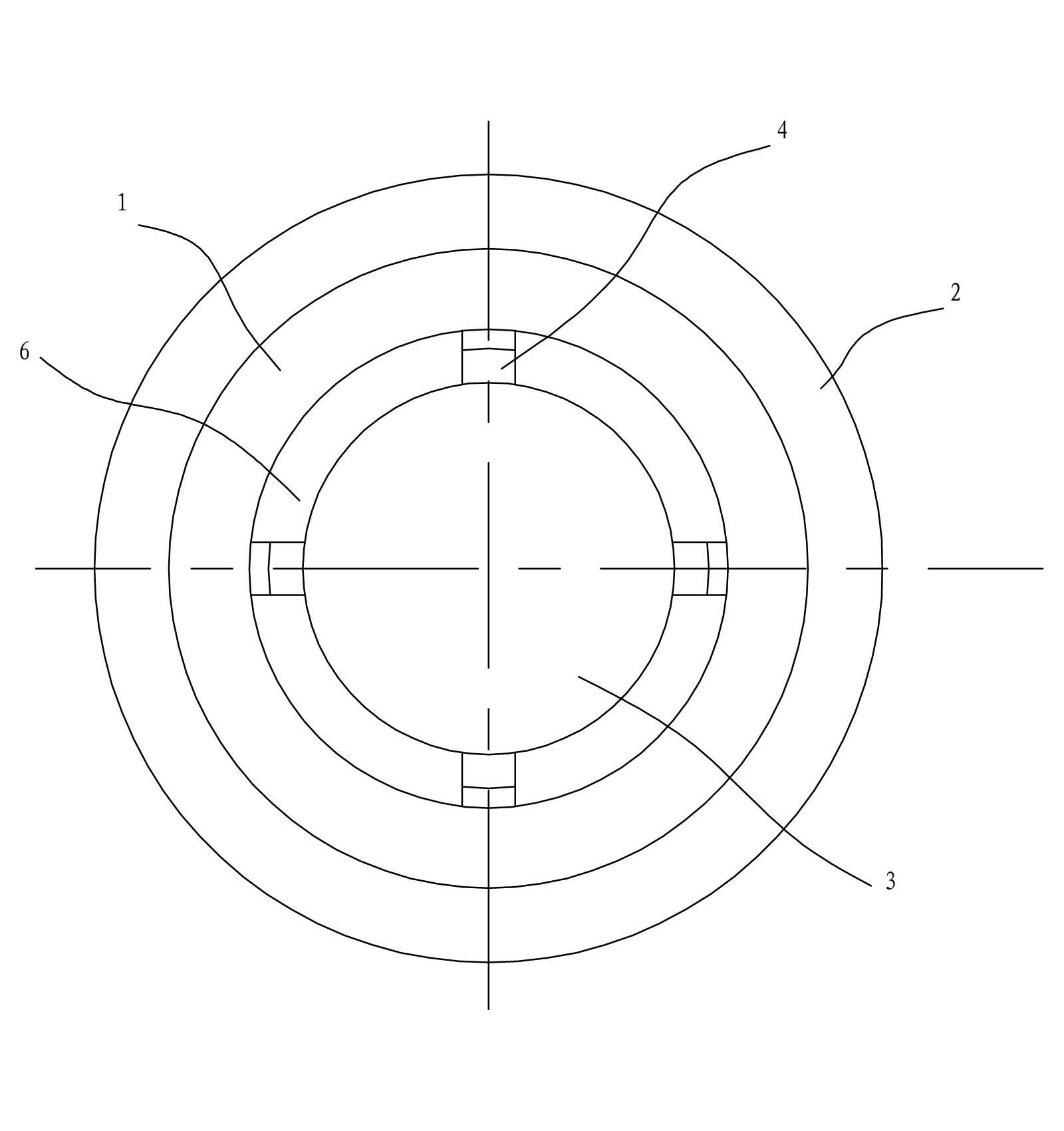

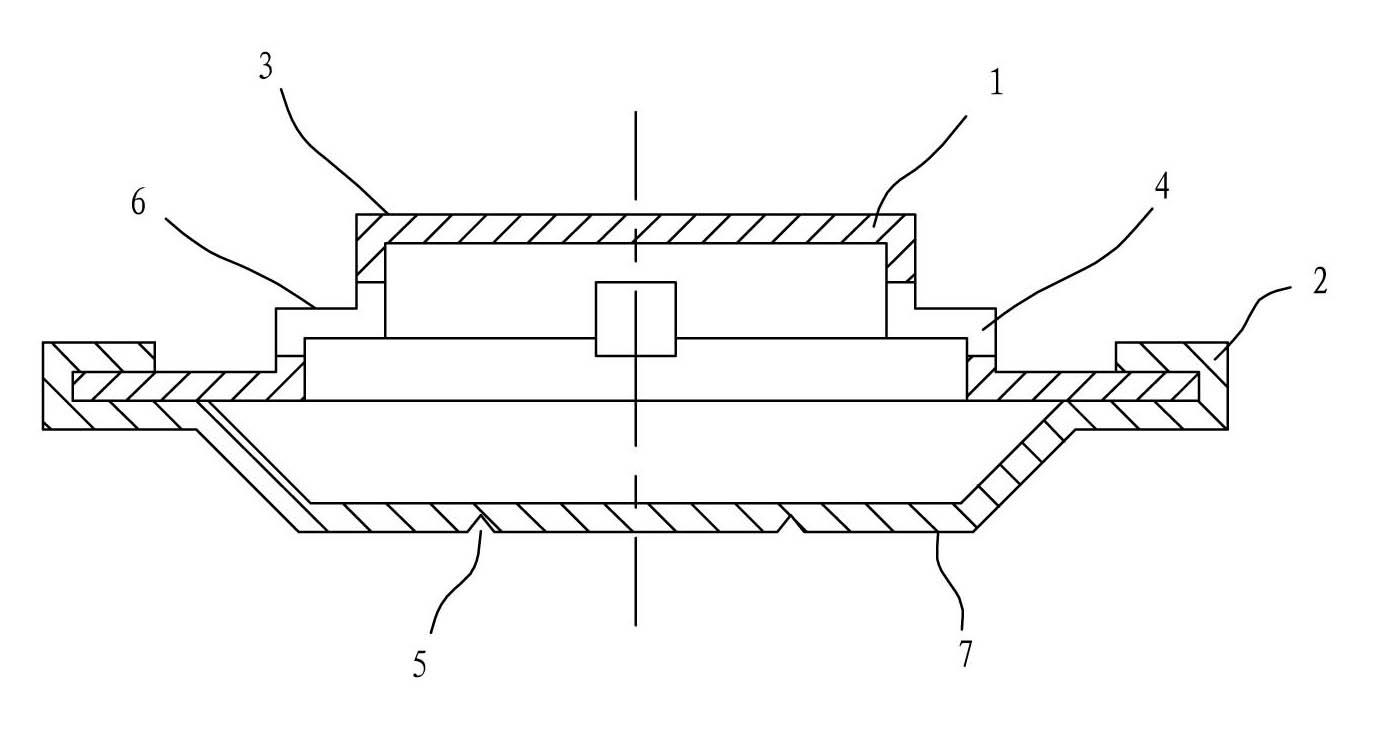

Login to View More Abstract

The invention discloses a lithium ion battery cover cap, which comprises a top cover and a bottom cover which are fixed hermetically and mutually, wherein an anode contact bulged upwards is formed on the top cover; a plurality of pressure relief holes are formed on the lateral surface of the anode contact; an annular anti-explosion notch score which is cracked under specific pressure is machined on the bottom cover; the edge of the bottom cover is bent upwards to wrap the edge of the top cover tightly; and a cycle of upward anti-explosion boss is also arranged along the periphery of the anode contact on the top cover. By the structure, the tightness of the lithium ion battery cover cap is enhanced, the internal resistance of a lithium ion battery is reduced, a stable anti-explosion pressure threshold value is also provided, and the safety of the lithium ion battery is enhanced.

Description

Lithium-ion battery cap technical field The invention relates to a battery cap, in particular to a lithium ion battery cap. Background technique With the development of the economy and the continuous improvement of people's living standards, various mobile electronic devices, such as mobile phones, digital cameras, notebook computers, etc., have been greatly popularized in society. These portable digital electronic products usually rely on batteries to work, thus forming a large demand for batteries. There are many kinds of existing batteries, such as nickel-cadmium batteries, nickel-metal hydride batteries, lithium-ion batteries, etc. Among them, lithium-ion batteries are widely used because of their advantages such as no memory effect and high energy density. Among them, the cylindrical lithium-ion battery occupies an important share in the battery market due to its standardized size, mature technology and equipment. Among the many components of lithium-ion batteries,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M2/04

CPCY02E60/12Y02E60/10

Inventor 杨福如刘喜信吕活胜

Owner 江门市朗达集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com