Hybrid excitation triggered double exciting winding MCR (magnetically controlled reactor)

A technology of double excitation windings and magnetron reactors, which is applied in the direction of transformer/inductor coil/winding/connection, irreversible AC power input conversion to DC power output, reactive power compensation, etc., which can solve the problem that demagnetization cannot fully play a role , blocking applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principle of compound excitation trigger is: when the body is manufactured, combined with the low-voltage external excitation method, an external excitation coil is added to the body device for compound trigger control. The excitation strength can also be weakened. Then solve the problem of rapid excitation and demagnetization.

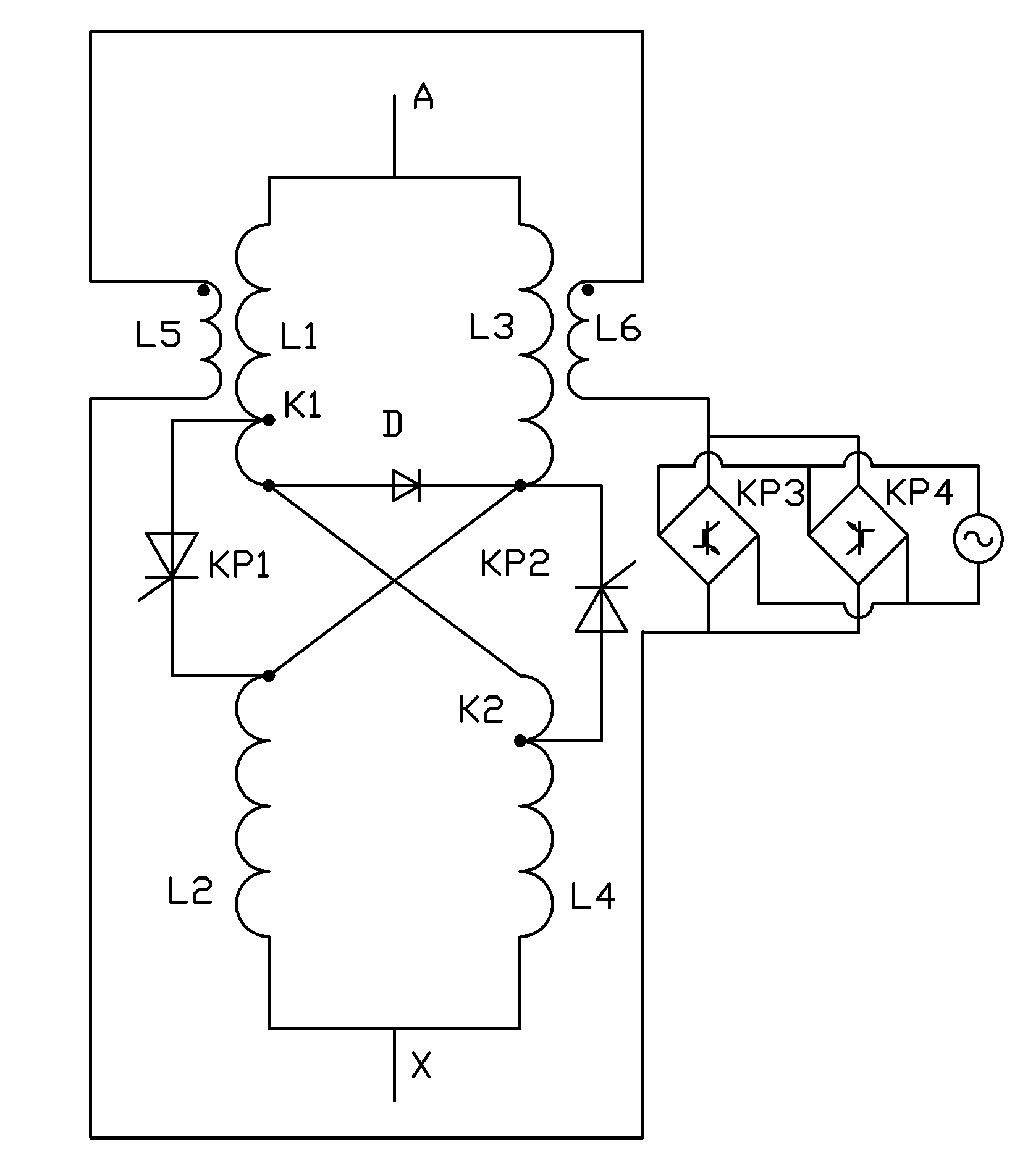

[0021] See figure 1 , Compound excitation trigger, double excitation winding MCR type magnetic control reactor, including two iron cores, coil L1, coil L2, coil L5 are wound on one iron core, coil L3, coil L4 are wound on the other iron core , Coil L6, the outlet end of coil L1 is connected to the inlet end of coil L4, the outlet end of coil L3 is connected to the inlet end of coil L2, and the four groups of coils of coil L1, coil L2, coil L3 and coil L4 form a cross-parallel structure . A tap K1 is drawn in the middle of the coil L1, and a controllable device KP1 is connected between the tap K1 and the incoming end of the coil L2, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com