Weight inspecting device

A technology for weight inspection and inspection of objects, which is used in measuring devices, weighing, material inspection, etc., and can solve problems such as power consumption and no special consideration for power saving countermeasures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

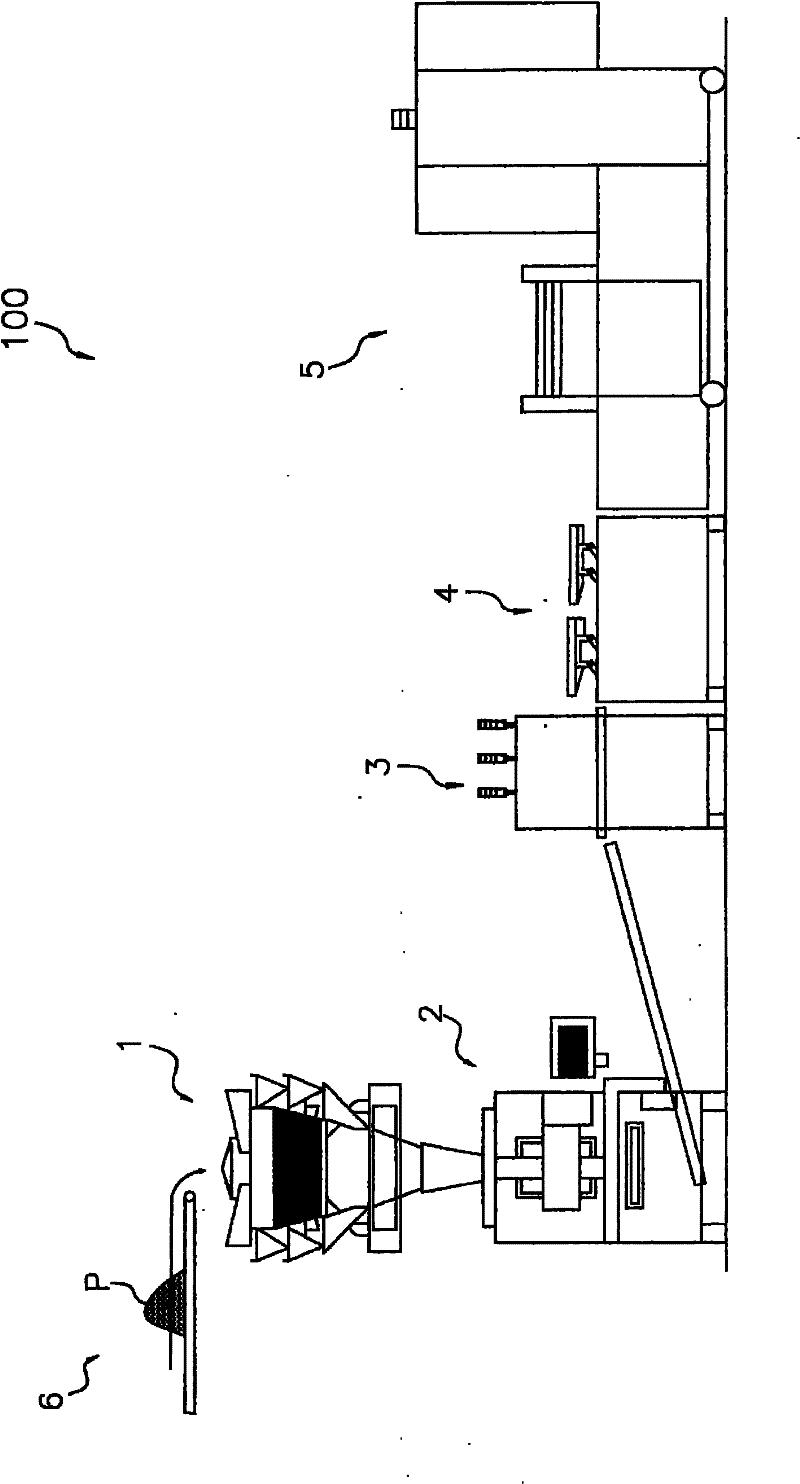

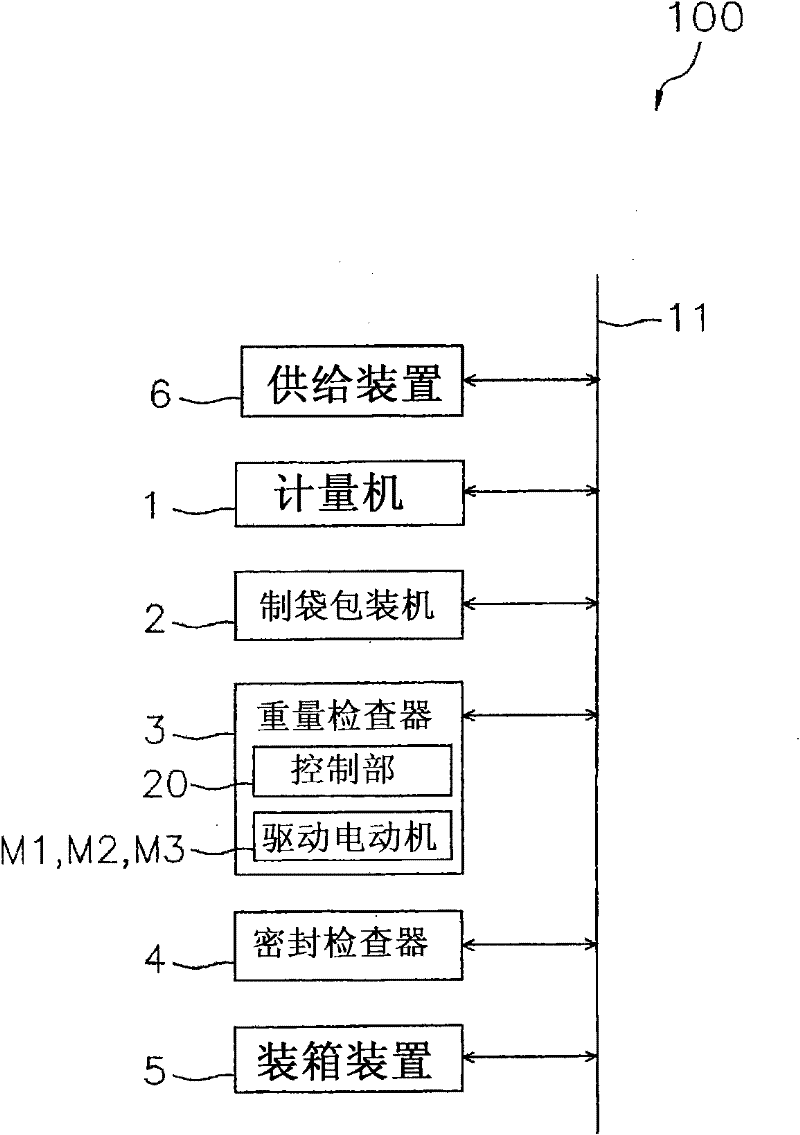

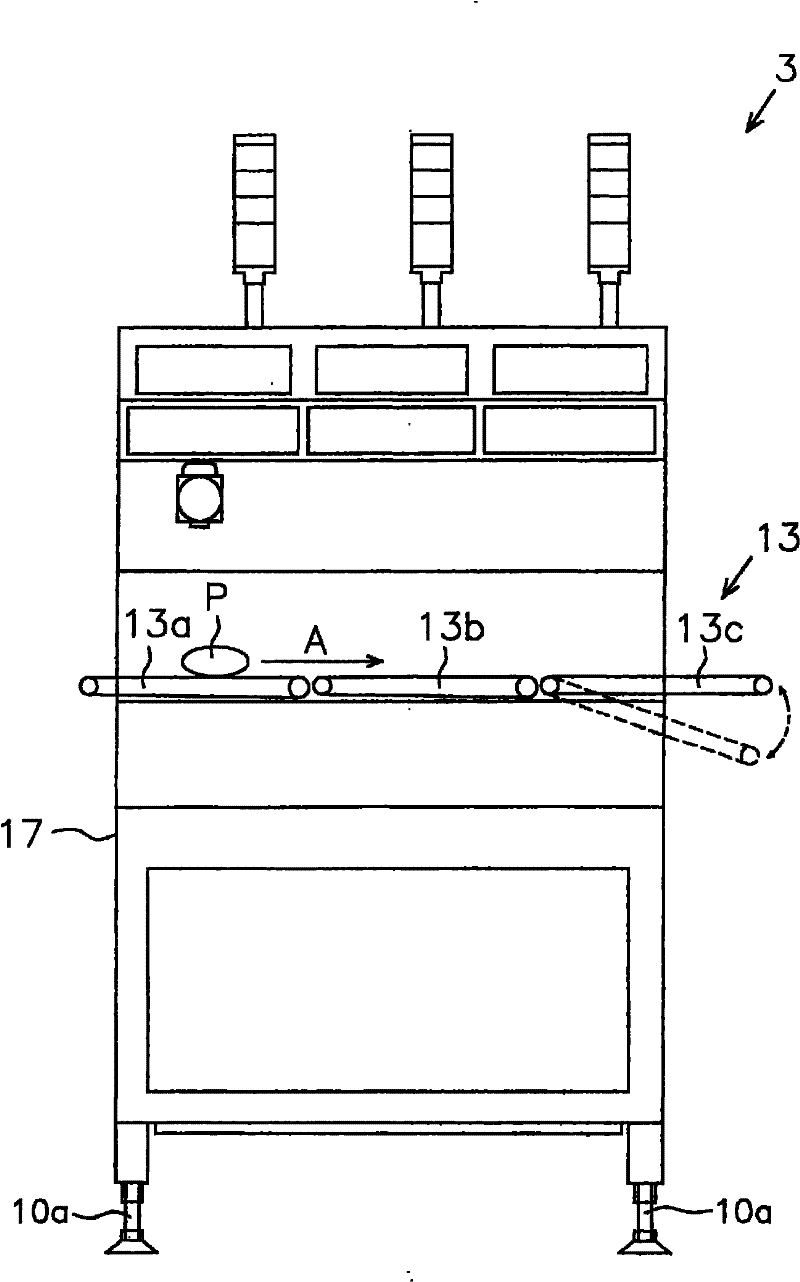

[0078] use Figure 1 to Figure 6 A weight inspection device according to one embodiment of the present invention will be described as follows.

[0079] [Structure of Production System 100]

[0080] The production system 100 of this embodiment, such as figure 1 with figure 2 As shown, a production line and a supply device 6 are included, and the production line includes a weighing machine 1 , a bag forming and packaging machine 2 , a weight checker (weight check device) 3 , a seal checker 4 and a box packing device 5 . These respective devices 1 to 6 operate in conjunction with each other by means of respective conveyor belts and the like, and carry out weighing, packaging and shipping operations of articles (products (inspected objects P)) supplied from the supply device 6 . In addition, each of the devices 1 to 6, such as figure 2 As shown, they are connected to each other by communication wires 11, and various signals, data, and other information are transmitted and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com