Motor driver for washing machine

A driving device and motor technology, applied in washing devices, control devices of washing machines, AC motor control, etc., can solve problems such as limited boosting and boosting effects, and achieve the effects of suppressing current consumption, improving efficiency, and achieving power saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

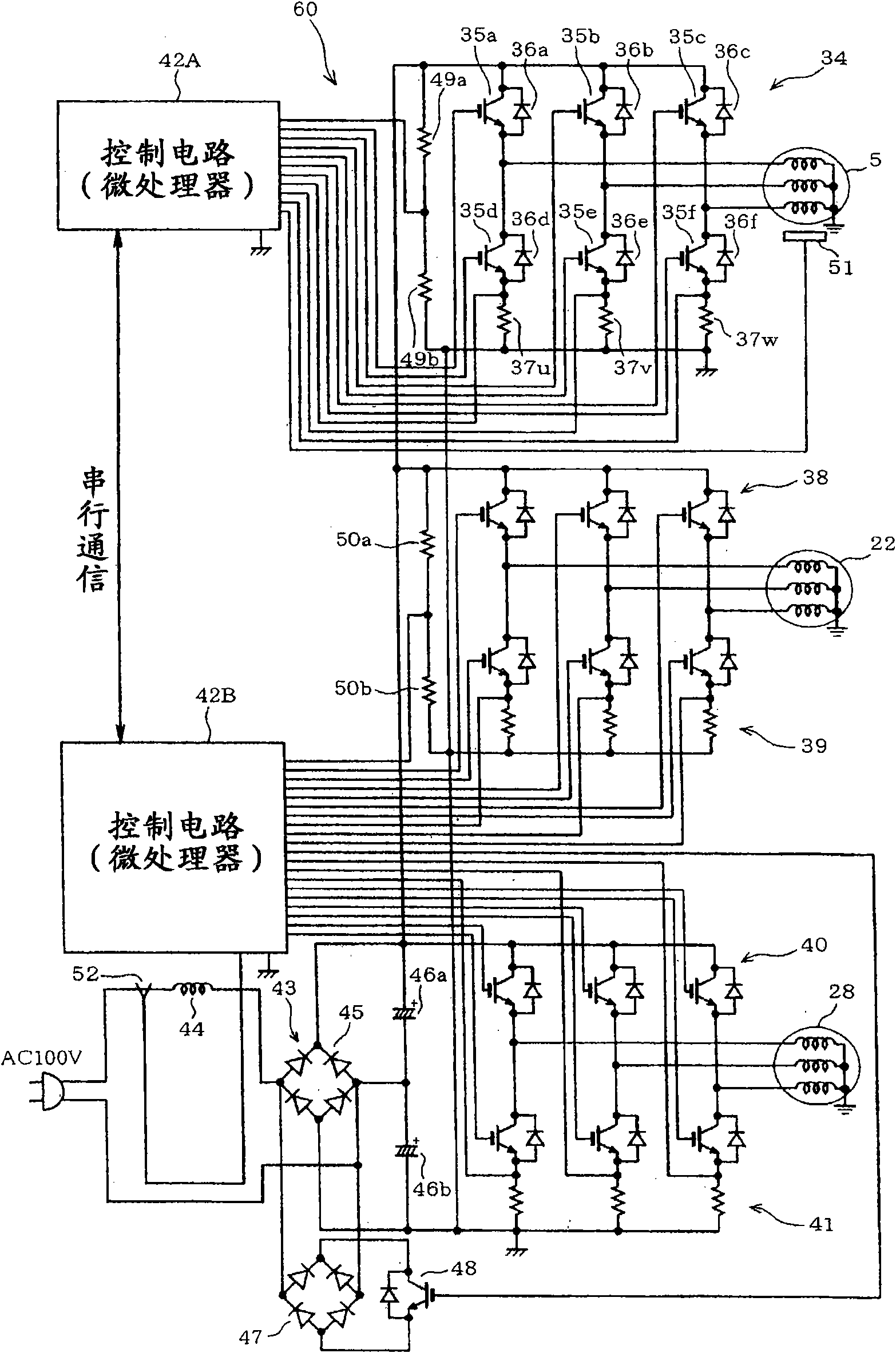

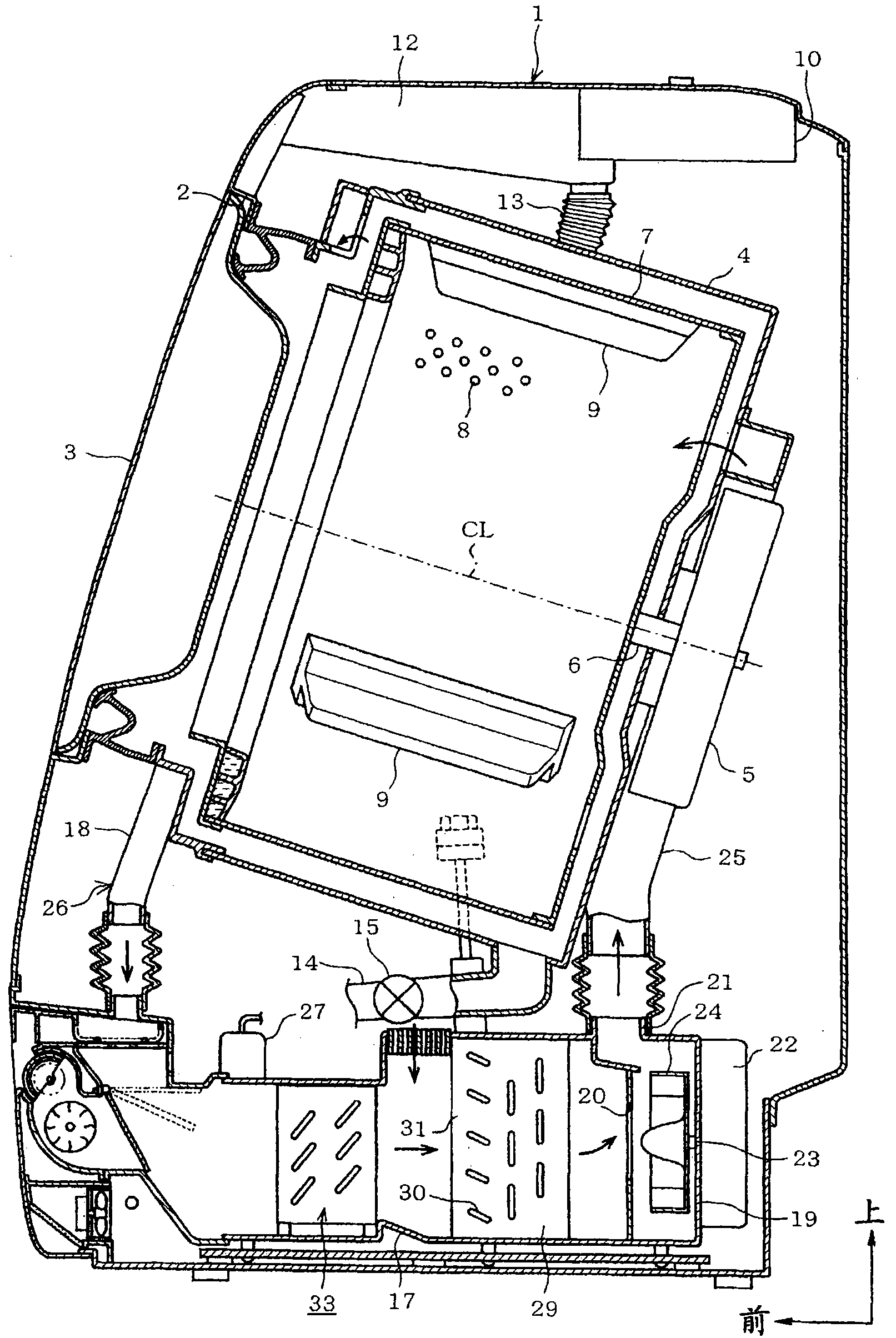

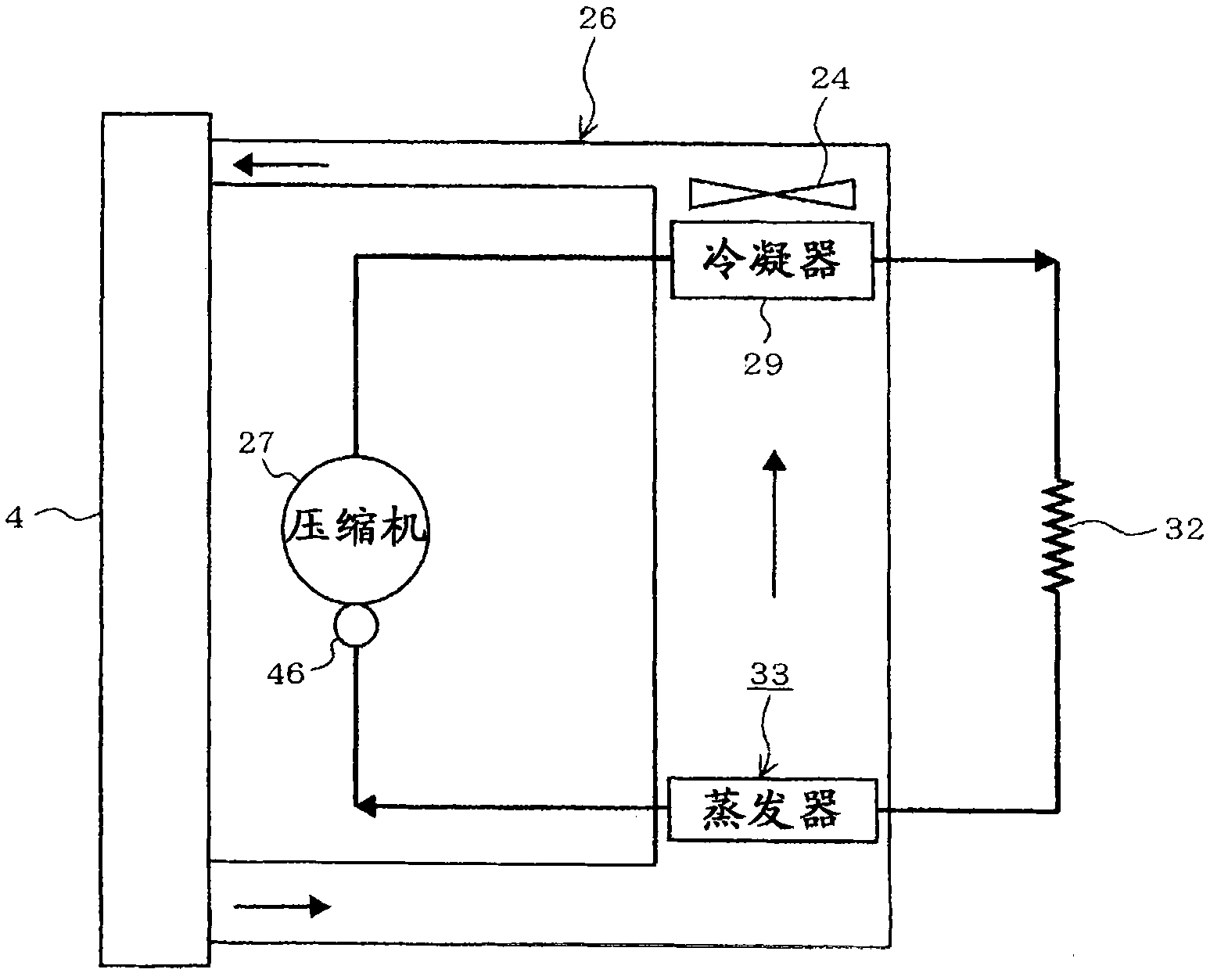

[0037] Below, refer to Figure 1 to Figure 8 The first embodiment will be described. figure 2 It is vertical section side view of constitution of drum type washing and drying machine. The outer case 1 is formed in a hollow shape having a front panel, a rear panel, a left side panel, a right side panel, a bottom panel, and a top panel, and a through-hole-shaped entrance and exit 2 is formed on the front panel of the outer box 1 .

[0038] A door 3 is attached to the front panel of the outer box 1 . The door 3 can be operated by the user from the front, and can be switched between the closed state and the open state. The entrance and exit 2 are closed under the closed state of the door 3, and the entrance and exit 2 are opened under the open state of the door 3.

[0039] The sink 4 is fixed inside the outer case 1. The water receiving tank 4 is formed in a cylindrical shape with a closed rear surface, and is arranged in an inclined state in which the axis line CL descends fr...

no. 2 Embodiment

[0105] Figure 9 and Figure 10 This is the second embodiment, and the same parts as those in the first embodiment are assigned the same symbols, and descriptions thereof are omitted, and different parts are described below. Figure 9 With Image 6 The corresponding figure shows the state in which the washer-dryer performs the final dehydration and then proceeds to the drying operation.

[0106] At this time, the final dehydration is carried out in four stages, and the maximum rotational speed of the drum motor 5 in each dehydration operation is set to gradually increase according to 400rpm, 700rpm, 950rpm, and 1700rpm.

[0107] Figure 10 express with Figure 5 The processing details corresponding to step S14. It is judged whether the setting of the rotating speed is more than 950 rpm (step S21), if it is more than 950 rpm (Yes), it is further judged whether it is more than 1450 rpm (step S22). If it is above 1450rpm (Yes), the short-circuit pulse is output three times ...

no. 3 Embodiment

[0111] Figure 11 This is the third embodiment, and the parts different from the second embodiment will be described. Figure 11 With Figure 10 In the corresponding figures, the content of the determination in steps S21A and S22A instead of steps S21 and S22 is different.

[0112] The control circuit 42B detects the AC input current (control parameter) of the driving power supply circuit 43 through the current sensor 52, and judges whether or not the effective value of the current is 3 amperes [A] or more (step S21A). If the current effective value is above 3 amperes (Yes), it is further judged whether it is above 5 amperes (step S22A). If it is above 5 amperes (Yes), execute step S23, output short-circuit pulses three times, and short-circuit the input terminals of the rectifier circuit 45 three times within a half cycle of the AC power supply voltage.

[0113] If it is less than 5 amperes (No), execute step S25, and output the short-circuit pulse twice.

[0114] That is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com