Optical fiber drawing furnace

A technology of drawing furnace and optical fiber, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of the influence of the outer diameter of the optical fiber and the turbulent airflow, and achieve the effect of saving electricity and improving heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

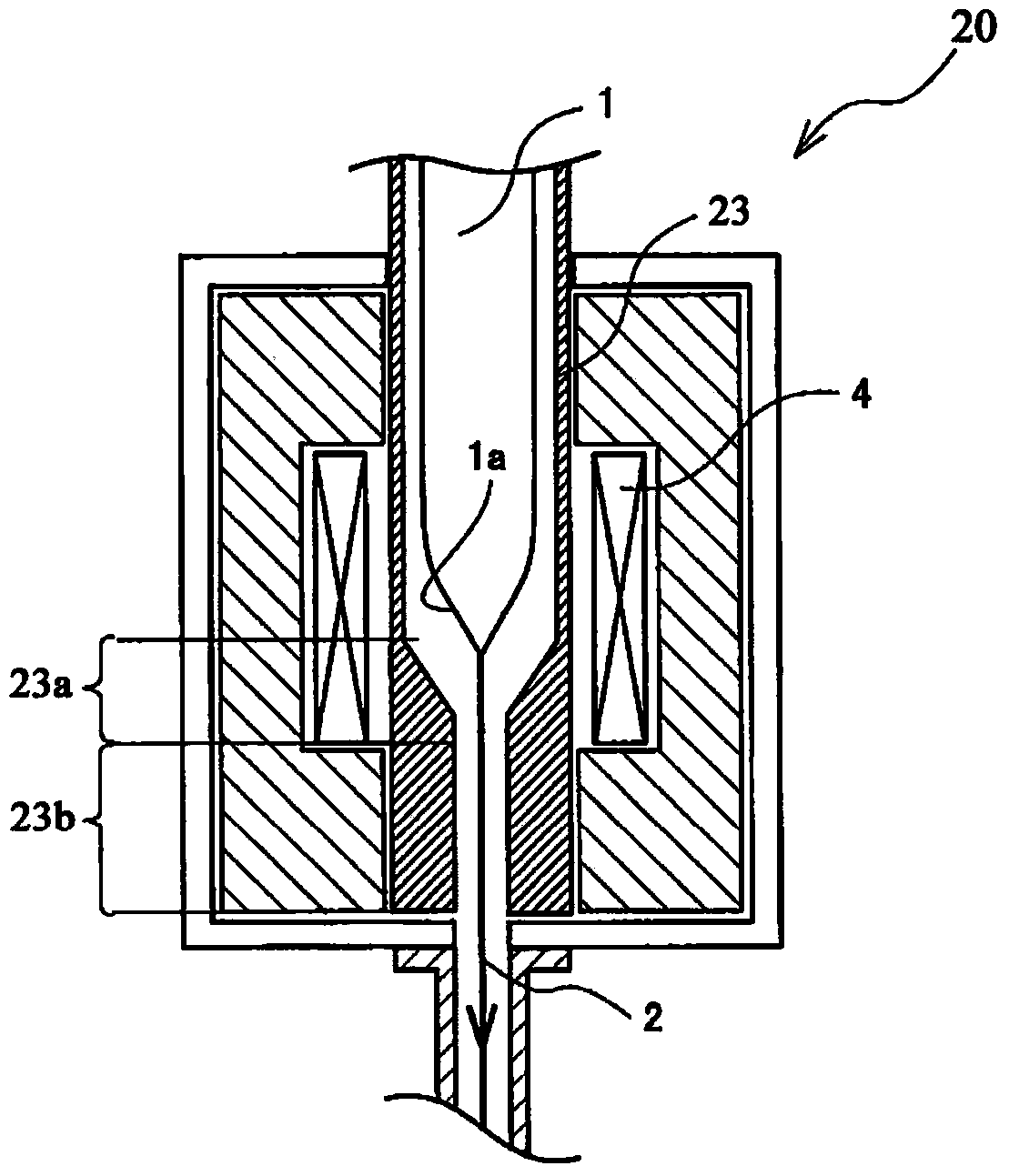

[0013] figure 2 It is a conceptual diagram showing the drawing furnace 20 disclosed in patent document 1. The drawing furnace 20 has a furnace tube 23 and a heater 4 for heating the furnace tube, and the optical fiber 2 is drawn by inserting the glass preform 1 for an optical fiber into the furnace tube 23 and heating and melting it. The optical fiber 2 hangs down from the lower end 1 a of the molten glass preform located in the center of the heater 4 and is drawn out downward. The furnace core tube 23 has: a reduced-diameter part 23a whose inner diameter is tapered along the shape of the lower end part 1a of the glass base material; and a reduced-diameter tube part 23b whose uniform inner diameter and outer diameter Unreduced uniform outer diameter.

[0014] According to the drawing furnace 20, the inert gas flow in the furnace core tube 23 can be formed into a laminar flow, and fluctuations in the outer diameter of the optical fiber can be suppressed. According to the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com