Temperature control method for reaching set temperature at equal time intervals at preheating stage of plastic machinery

A technology for setting temperature and plastic machinery, applied in the field of temperature control in the preheating stage of plastic machinery, can solve the problems of energy waste, limited energy saving effect, complicated temperature control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

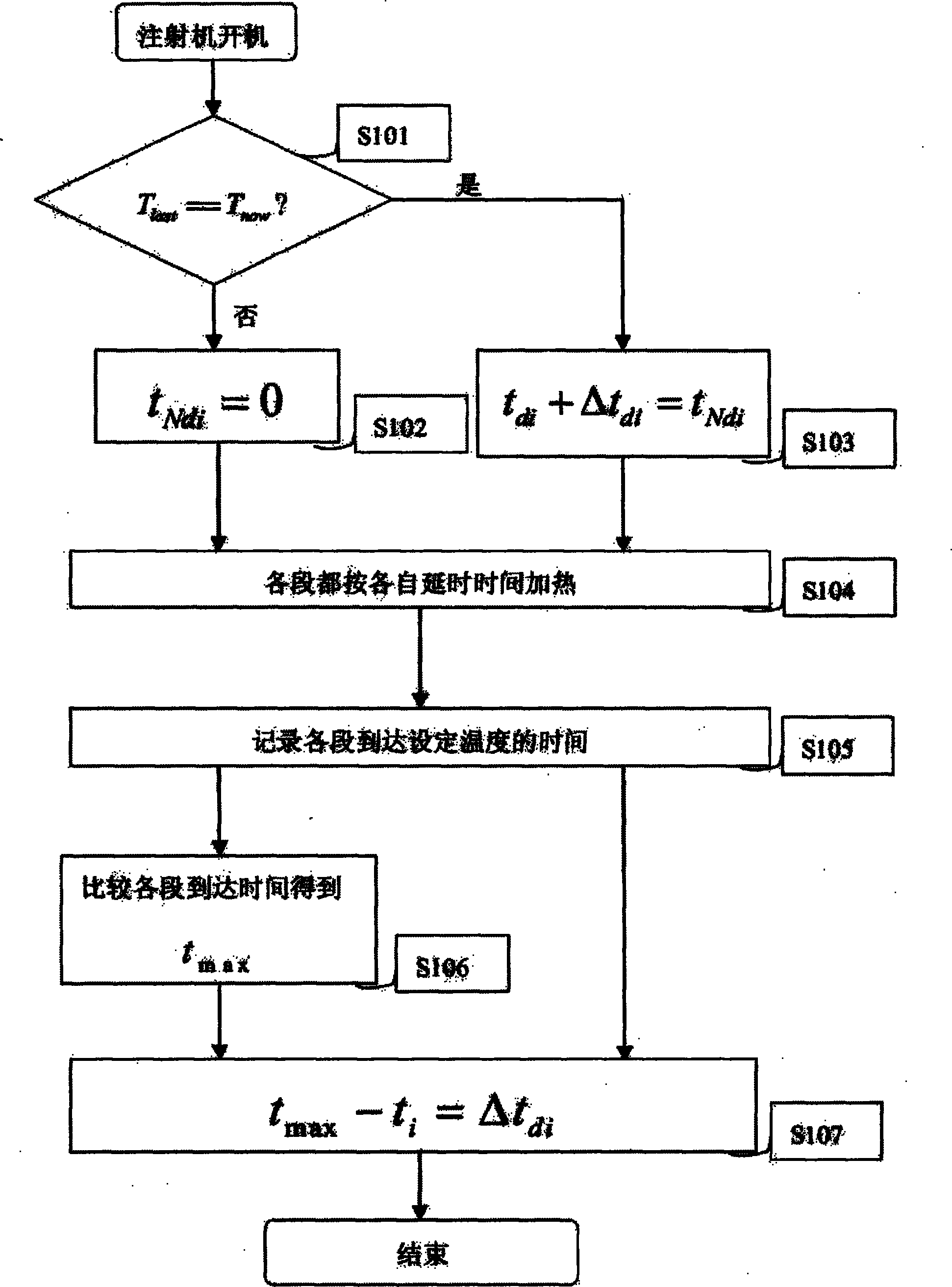

[0023] The specific implementation process of the temperature control method for isochronously reaching the set temperature in the preheating stage of the present invention will be described in detail in conjunction with each accompanying drawing.

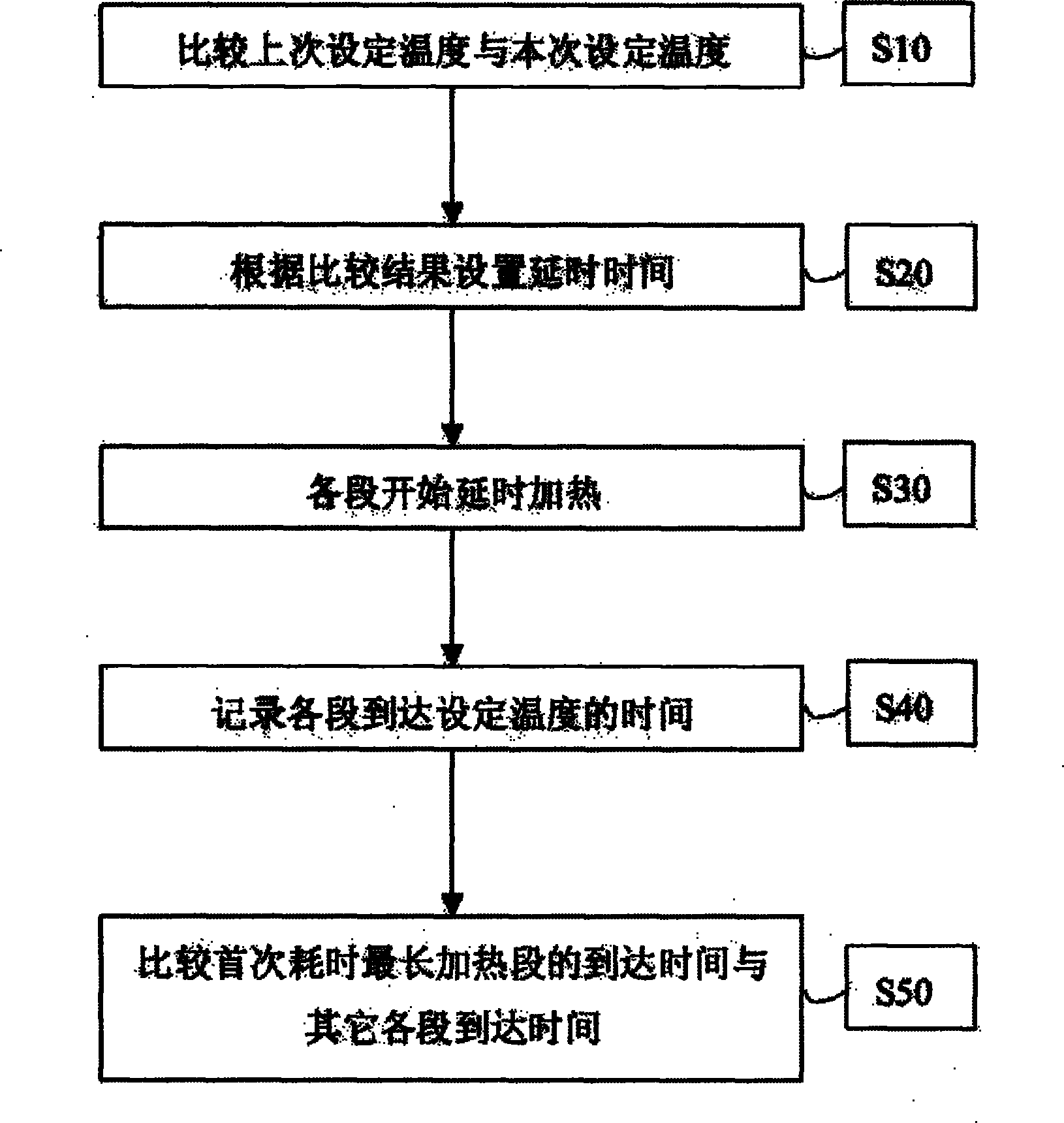

[0024] refer to figure 1 , this figure is a flow chart of the main realization process of the isochronous arrival of the set temperature temperature control method in the preheating stage of the plastic mechanical barrel and the head mold of the present invention. The main process of utilizing the present invention to control the temperature of the plastic machinery barrel and the mold of the die is as follows:

[0025] Step S10, when the system is turned on, compare the set temperature T now Compared with the last boot set temperature T last , judging whether the two set temperatures are exactly the same T last = = ? T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com