Device and method for separating printed products out of a stack

A printing product and separate printing technology, which is applied in the field of separating printed products from stacks, can solve problems such as inability to adjust movement, stuck printed products, expensive transmission systems, etc., and achieve the effect of protecting printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

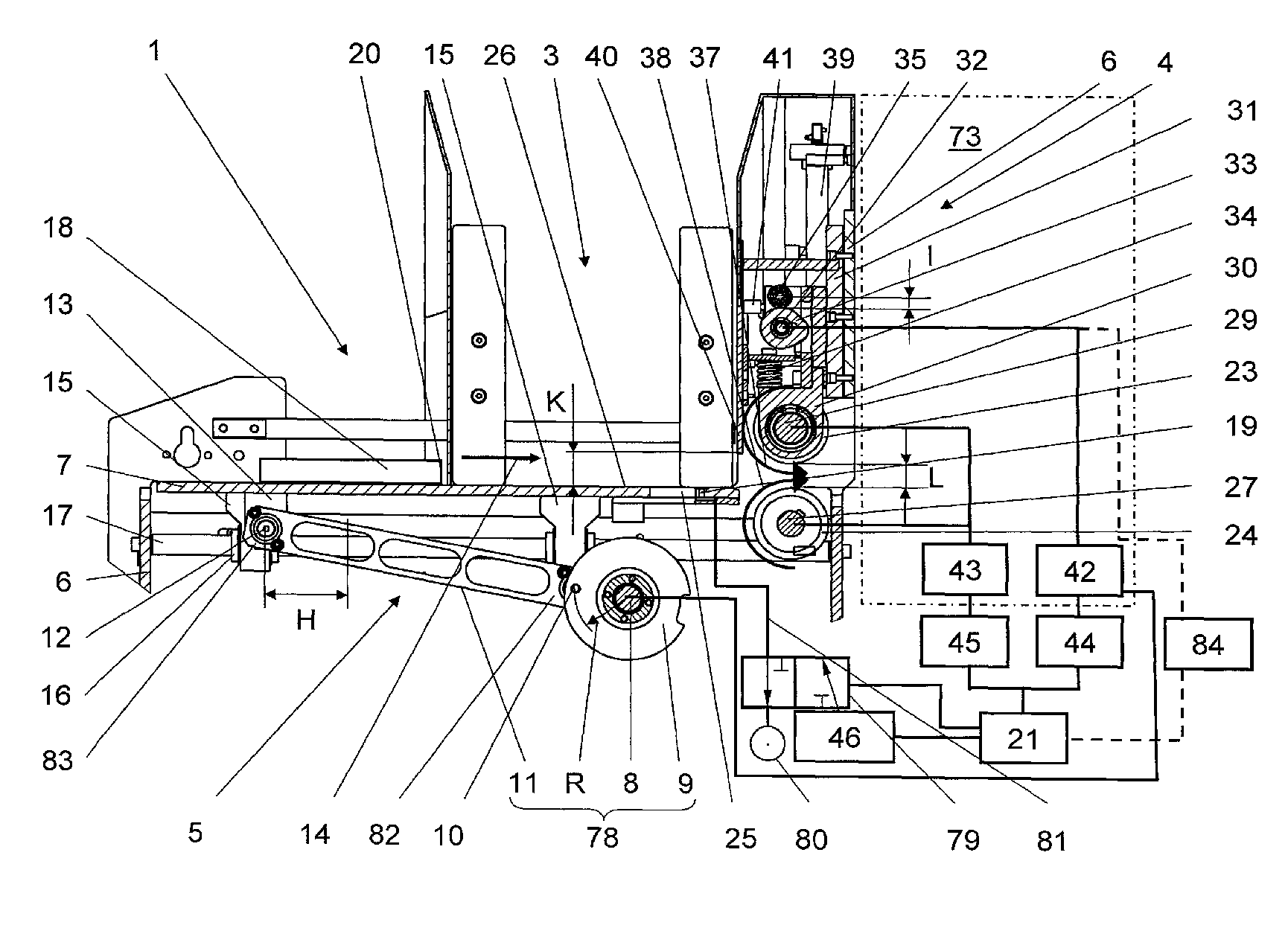

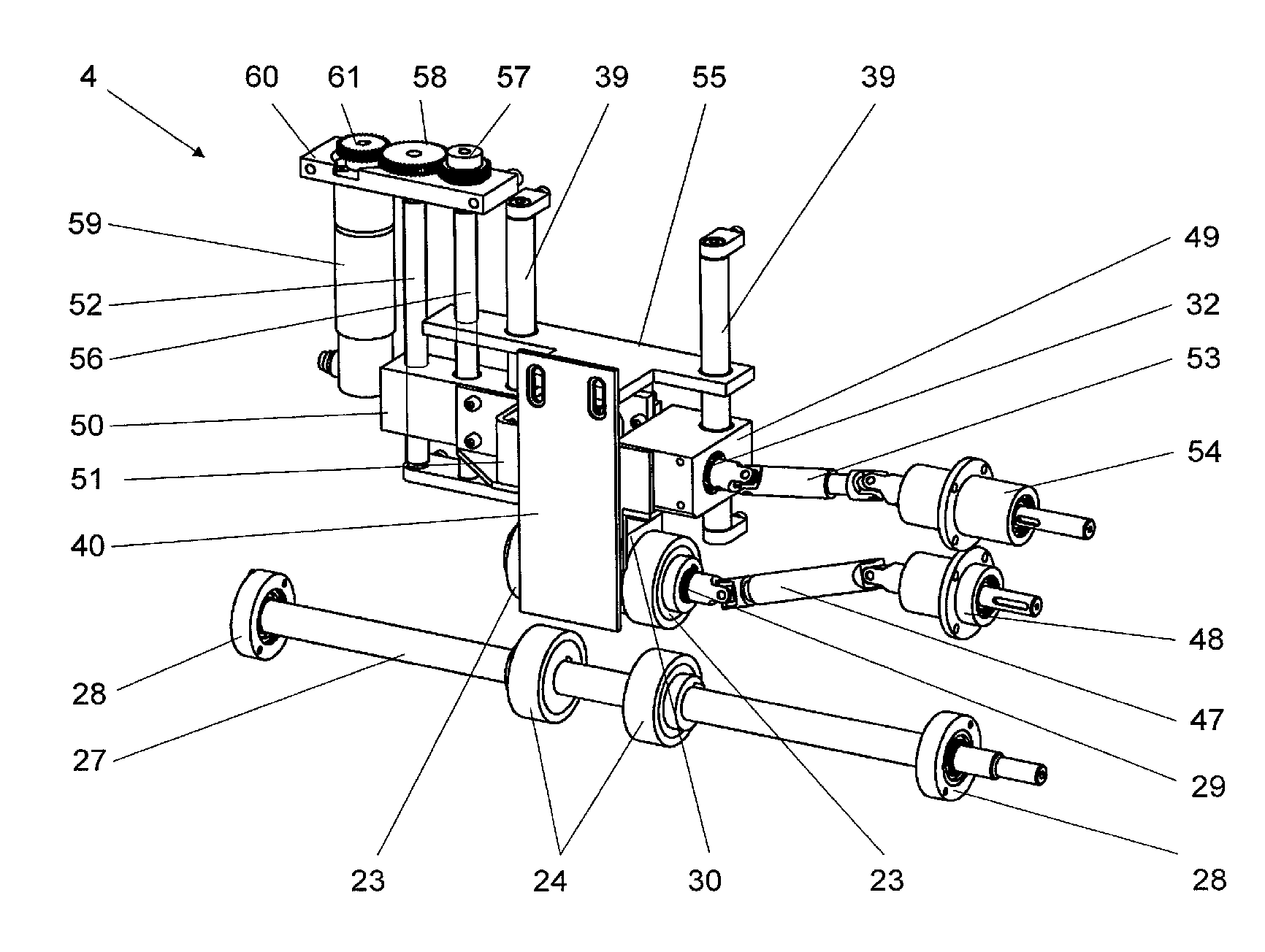

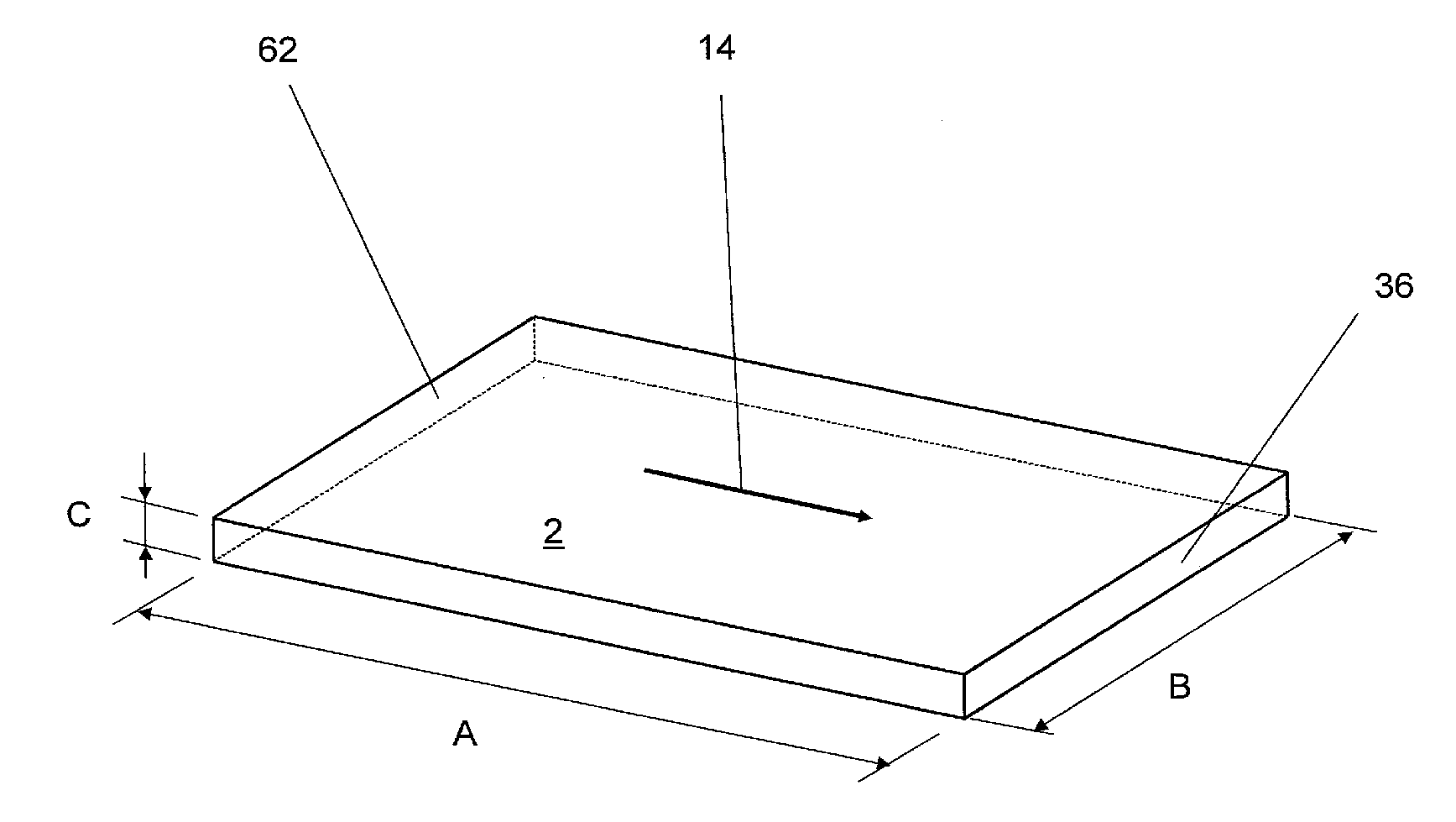

[0038] figure 1 shown for printing products 2, 2a, 2b, 2c ( image 3 , Figures 6a-6f ) of the separating device 1, the separating device is mainly composed of a material box 3, a conveying device 4 and a moving device 5, which are respectively fixed on the frame 6. The frame 6 is, for example, a welded structure with a plurality of parts, but may also have joint parts that are screwed to each other, or a cast structure.

[0039] The mobile device 5 comprises a mobile stage 7 and the components required for the translational vibrational movement of the mobile stage. One such component is the drive shaft 8 to which a crank disk 9 is fastened, which in turn is rotatably coupled to the first end 82 of the connecting rod 11 via the first shaft 10 . The opposite second end 83 of the connecting rod 11 is rotatably connected via the second shaft 12 to the first holder 13 , which is itself fixed on the moving table 7 . In order to achieve an oscillatory translational movement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com