Heat resistance/environmental protection type high viscosity and high strength SEBS adhesive and preparation method thereof

An environmentally friendly, high-viscosity technology, used in non-polymer adhesive additives, adhesives, adhesive types, etc., can solve the poor environmental performance of ordinary SBS adhesives, low bonding strength, aging resistance / heat resistance indicators Not ideal and other problems, to achieve the effect of long opening time, good temperature resistance, and large operating time flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

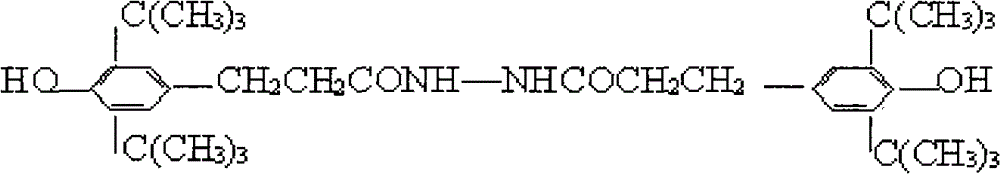

[0027] Temperature-resistant / environmentally friendly high-viscosity and high-strength SEBS adhesive, which includes the following components: SEBS rubber, tackifying resin (including C 5 Petroleum resin, terpene resin, rosin and 138 resin mixture), antioxidant 300, 6# solvent gasoline, ester solvent (methyl acetate, ethyl acetate) solvent.

[0028] Among them, the weight percentages of SEBS rubber, tackifying resin, antioxidant 300, 6# solvent gasoline and ester solvents are: 15%, 28%, 0.5%, 48.5%, and 8%.

[0029] C in tackifying resin 5 The weight ratio of petroleum resin, terpene resin, rosin and 138 resin is 1:2:3:10 in sequence.

[0030] The weight ratio of methyl acetate and ethyl acetate in the ester solvent is 2:3 in turn.

[0031] The preparation method of the above-mentioned temperature-resistant / environmental protection type high-viscosity high-strength SEBS glue comprises the following steps in turn:

[0032] a. First put quantitative 6# solvent gasoline and es...

Embodiment 2

[0043] Temperature-resistant / environmentally friendly high-viscosity and high-strength SEBS glue, which includes the following components: SEBS rubber: 11%, rosin: 4%, rosin pentaerythritol ester: 5%, terpene resin: 2.8%, C 9 Petroleum resin: 12%, antioxidant 330: 0.2%, methyl acetate: 6%, butyl acetate: 10%, 6# solvent gasoline: 49%.

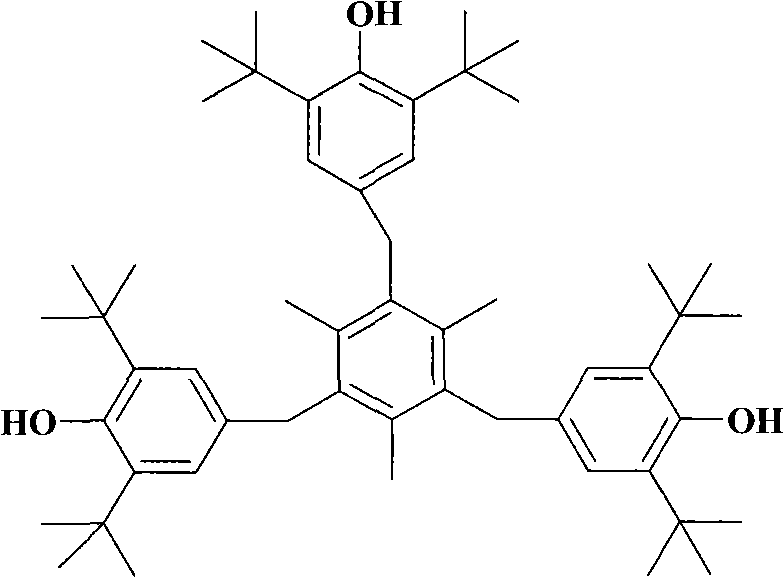

[0044] Antioxidant 330, scientific name 1,3,5-trimethyl-2,4,6-tris(3,5-tert-butyl-4-hydroxybenzyl)benzene. It is a high molecular weight polybasic hindered phenol. It has the characteristics of no pollution, no discoloration, low toxicity, and high antioxidant capacity.

[0045] Structural formula:

[0046]

[0047] Molecular formula: C 54 h 78 o 3

[0048] When preparing the above-mentioned temperature-resistant / environment-friendly high-viscosity and high-strength SEBS glue, first put quantitative 6# solvent gasoline and ester solvents (methyl acetate, butyl acetate) into the mixer, start the machine to stir evenly; then put the SEBS...

Embodiment 3

[0052] Temperature-resistant / environment-friendly high-viscosity and high-strength SEBS glue, which includes the following components: SEBS rubber: 14%, C 5 Petroleum resin: 4.5%, 138 resin: 4.5%, rosin pentaerythritol ester: 2.8%, terpene resin: 10%, antioxidant 300: 0.2%, butyl acetate: 8%, ethyl methyl carbonate: 8%, 6 #Solvent gasoline: 48%.

[0053] The preparation method is the same as in Example 1. This method is used to prepare high-viscosity and high-strength SEBS glue.

[0054] The product obtained by this method can replace solvent-based neoprene, and can reach the viscosity of neoprene, but its solid content is higher than that of neoprene, low in VOC content, and less harmful to human body. It is an environmentally friendly adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com