Method for depositing back electrode in solar cell production

A technology of solar cells and deposition methods, which is applied in the field of solar cell production, can solve problems such as the influence of the next process, low target utilization rate, and increased scrap rate, so as to achieve short vacuuming time, reduce production and maintenance costs, and utilize rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

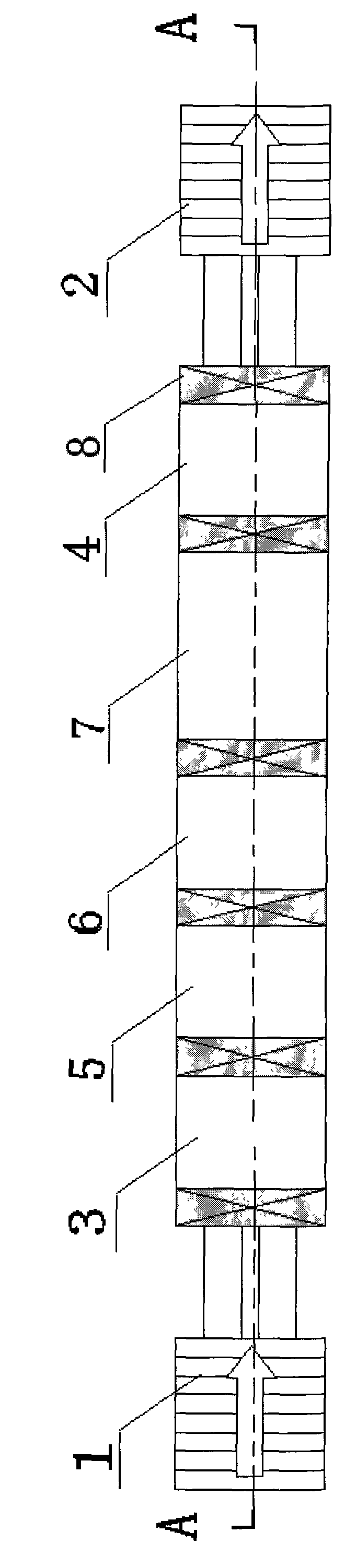

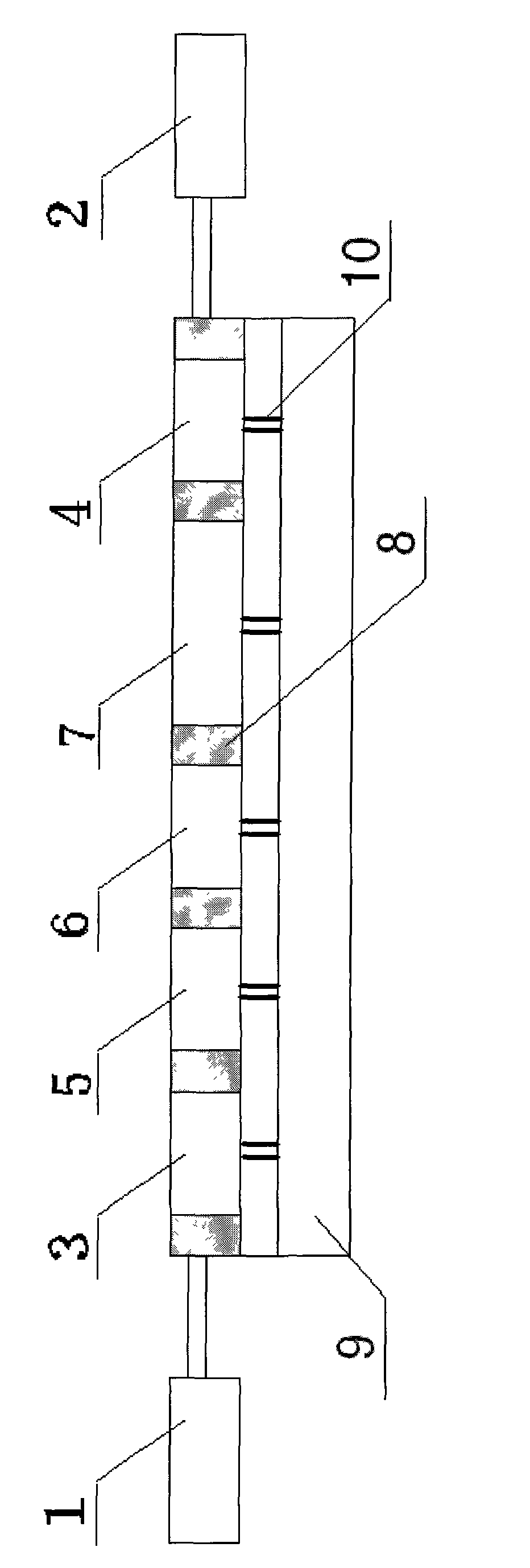

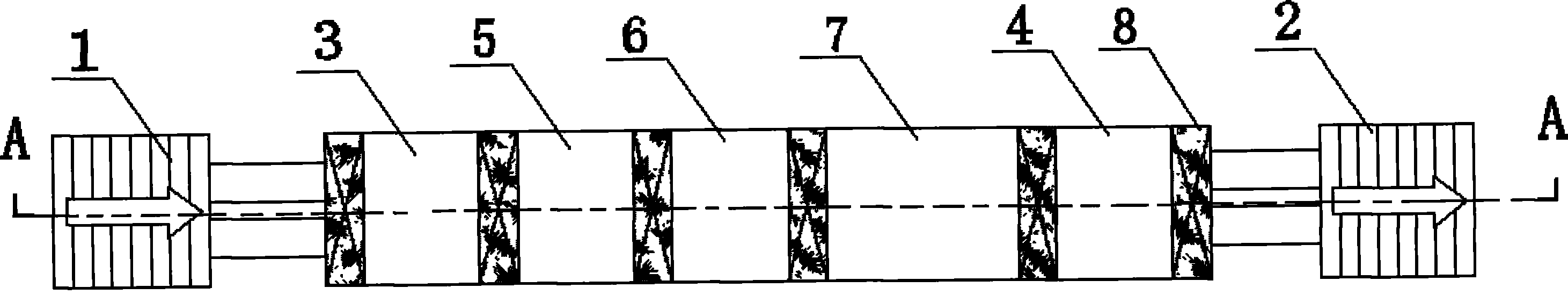

[0011] attached by figure 1 , 2 Shown: this method is to adopt the magnetron sputtering equipment of sputtering back electrode on the back of solar cell to realize through the following steps, described magnetron sputtering equipment is a tunnel type structural form, and it comprises sheet-feeding stage 1, exits Chip stage 2, buffer chambers 3, 4, heating chambers 5, 6, sputtering chamber 7, the buffer chambers 3, 4, heating chambers 5, 6, sputtering chamber 7 between each chamber Separated by a valve 8, two buffer chambers 3 and 4 arranged at both ends, two heating chambers 5 and 6 arranged side by side in the middle and a sputtering chamber 7 constitute the main body of the magnetron sputtering equipment. A vacuum system 9 is provided below each chamber of the main body of the injection equipment. The vacuum system 9 is connected to the buffer chambers 3, 4, the heating chambers 5, 6 and the sputtering chamber 7 through a vacuum pipeline 10.

[0012] The specific steps of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com