Tank for working fluids of motor vehicles

A technology of working fluid and box body, which is applied in the direction of vehicle components, arrangement combined with internal combustion engine fuel supply, exhaust treatment, etc., to achieve the effect of improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

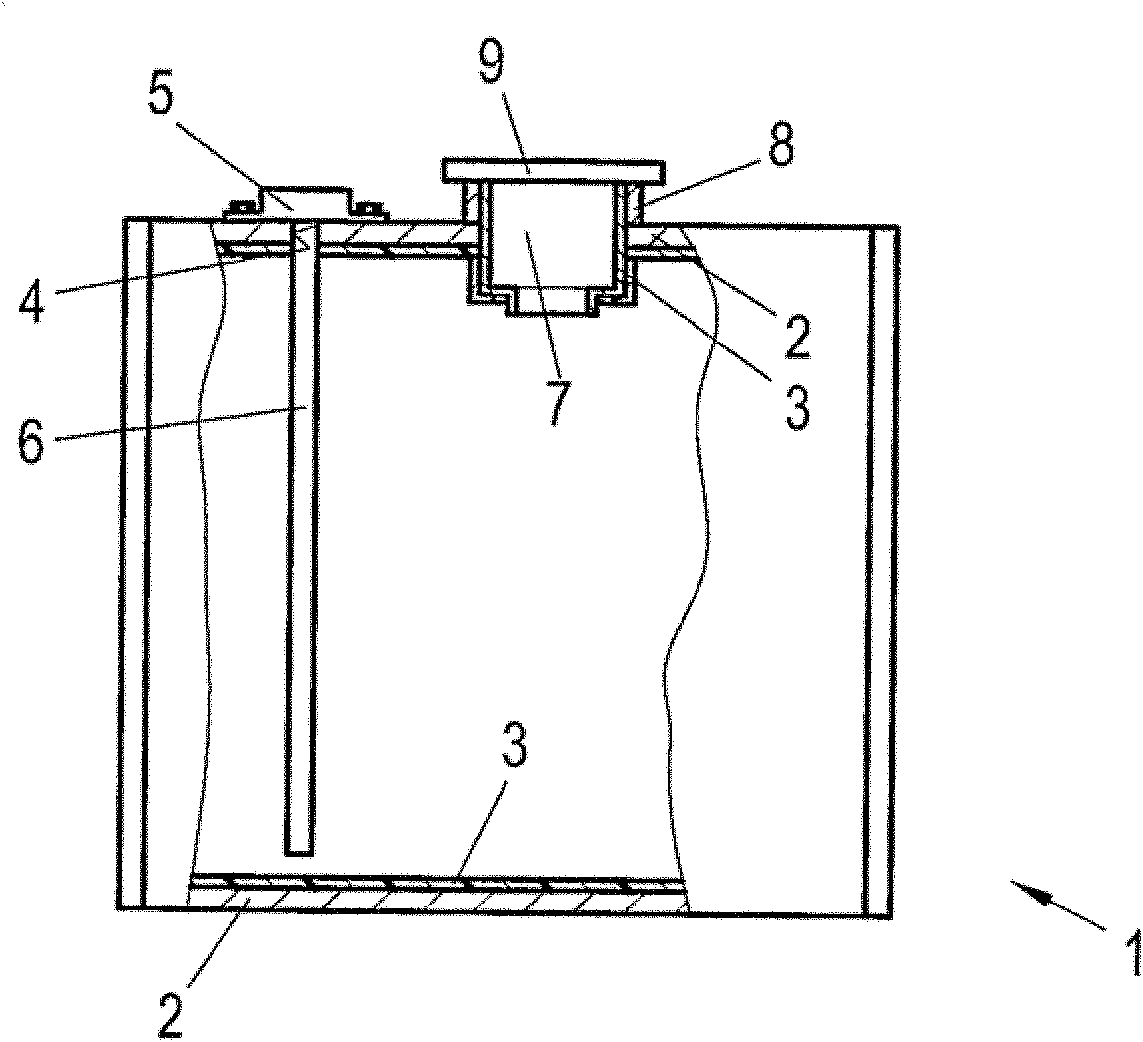

[0022] figure 1 Shown is a tank 1 which is intended to contain aggressive operating fluids of the motor vehicle, for example catalytic converter urea solution. The housing 1 can contain any built-in components such as partitions, splash guards, etc. for fuel, etc.

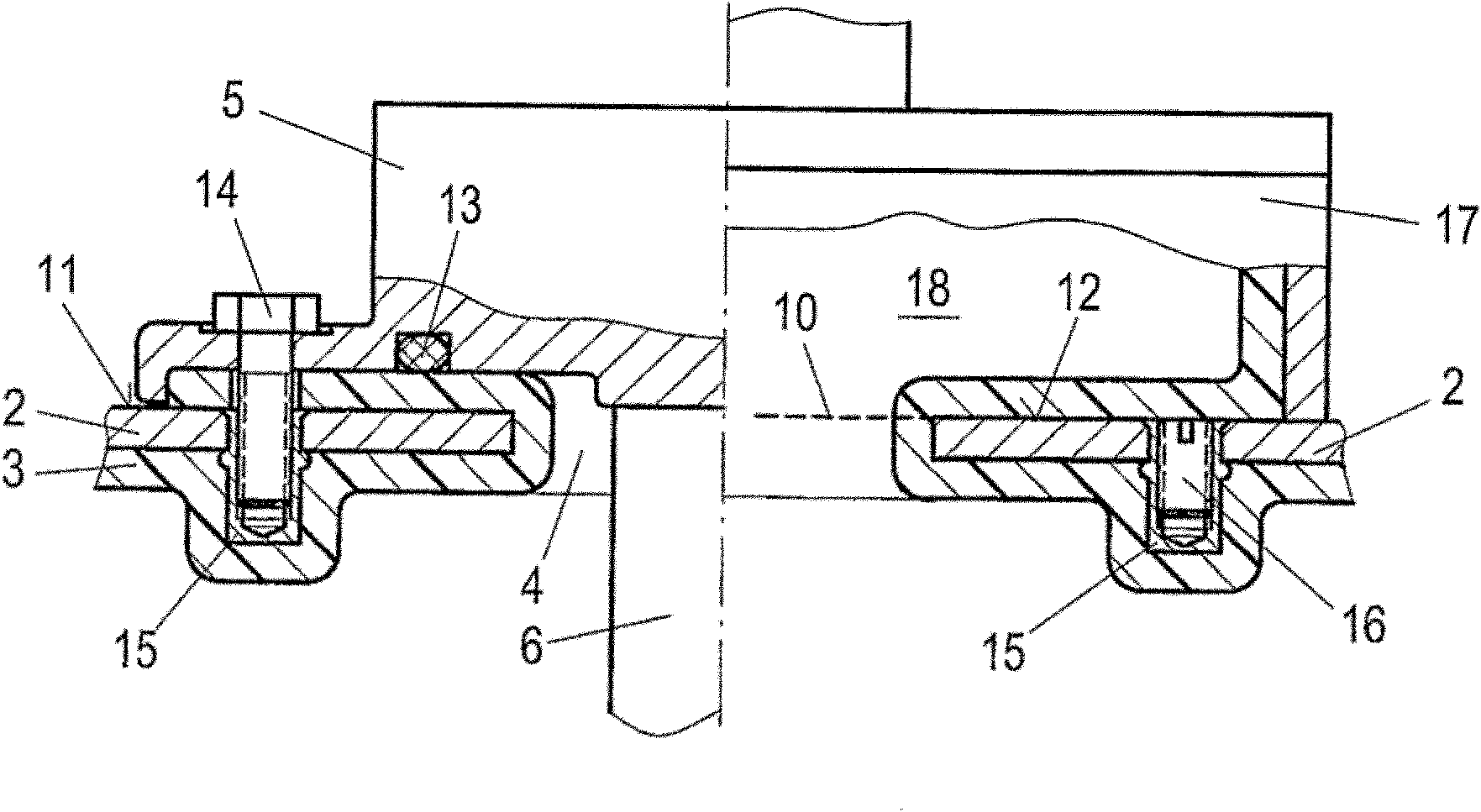

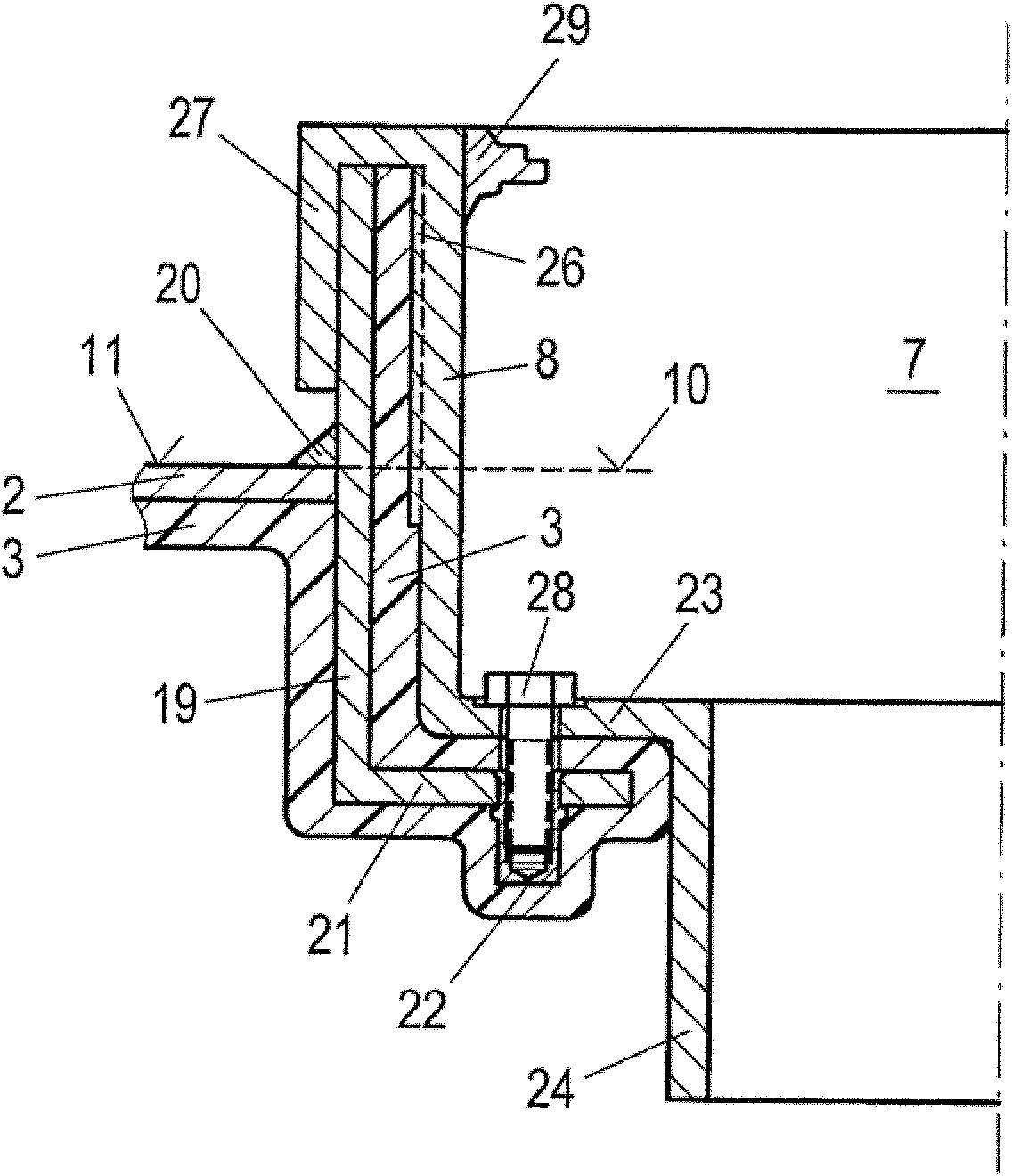

[0023] The housing 1 has a wall 2 made of metal, preferably aluminum. The metal wall 2 is provided on its inner side with a plastic coating 3 which thus lines the entire box interior.

[0024] The plastic coating 3 is resistant to the working fluid (here urea solution) to be accommodated. Suitable plastics for the plastic coating are, for example, polyolefins such as HPDE (high-density polyethylene), MDPE (medium-density polyethylene), LDPE (low-density polyethylene) or LLDPE (linear low-density polyethylene).

[0025] The plastic coating 3 is produced "in situ" on the metal wall 2 by means of rotational molding methods known in the prior art. For this purpose, the plastic material is introduced into the tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com