Horizontal pipe falling film evaporator

A horizontal tube falling film and evaporator technology, applied in horizontal tube evaporators and other directions, can solve the problems of reducing the condensation heat transfer area, increasing the resistance in the tube, reducing the condensation heat transfer efficiency, etc., to increase condensation heat transfer, improve heat transfer The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

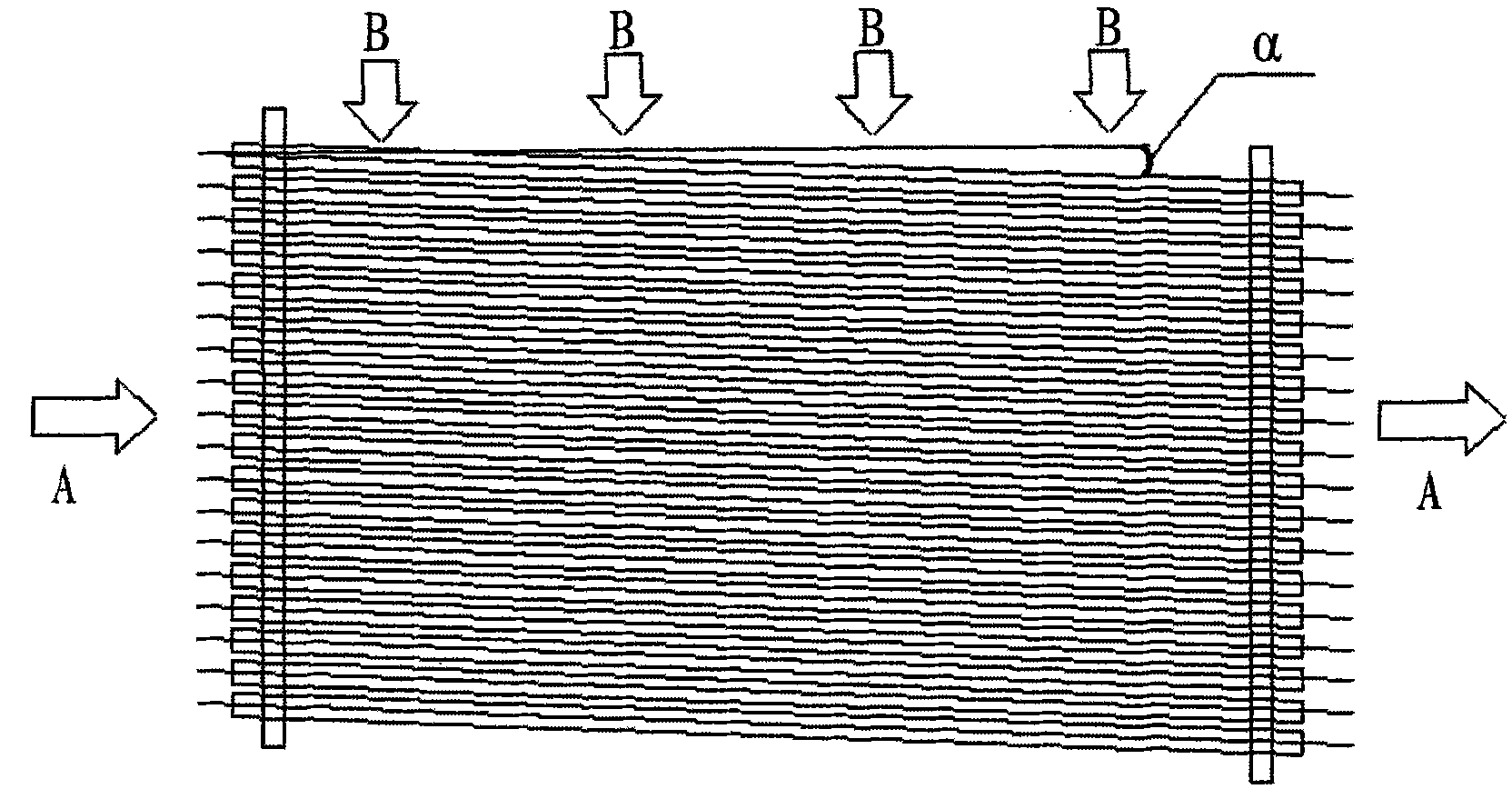

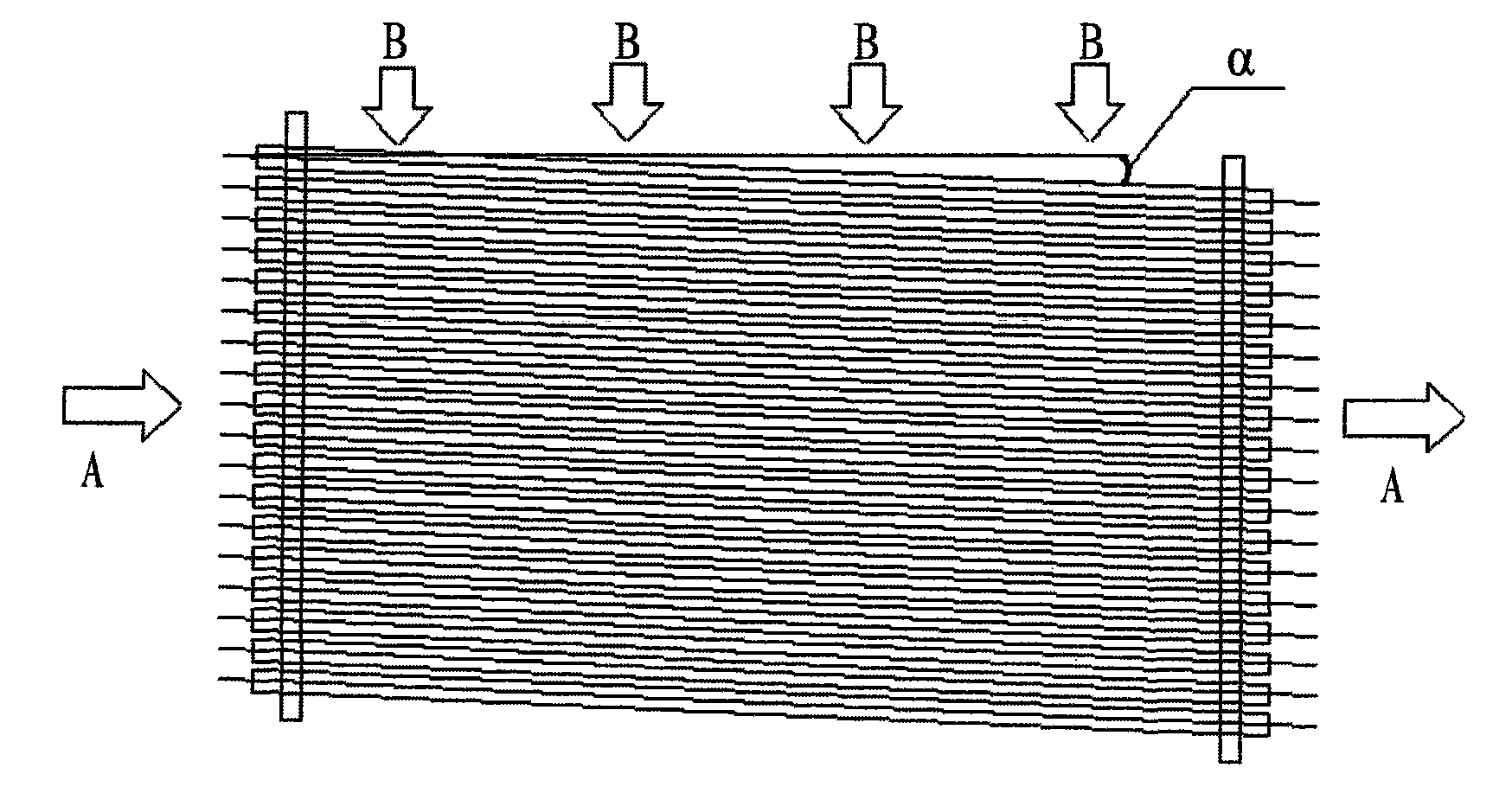

[0014] see figure 1 , which shows a preferred embodiment of a horizontal tube falling film evaporator of the present invention, including heat exchange tube bundles with internally flowing steam, wherein the direction of flowing steam figure 1 In the A direction shown in , the direction of the heat exchange spray water is figure 1 In the B direction shown in , the heat exchange tube bundles are arranged obliquely downward along the steam flow velocity direction. More specifically, the heat exchange tube bundle is inclined downward by 2° to 6° along the steam flow velocity direction. In this embodiment, the angle of inclination α is 5° downward, as figure 1 shown.

[0015] Preferably, the heat exchange tube bundle of the present invention includes two or more heat exchange tubes. The heat exchange tubes are arranged parallel to each other, and are inclined downward by 2° to 6° in the direction along the steam flow velocity. In this embodiment, the angle of inclination α is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com