Method for repairing arc-seam weld porosity defects of titanium alloy sheets through hot rolling

A welding seam porosity and hot rolling technology, which is applied in the direction of welding power supply, welding equipment, resistance welding equipment, etc., can solve the problems of large local deformation, deformation, and small welding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

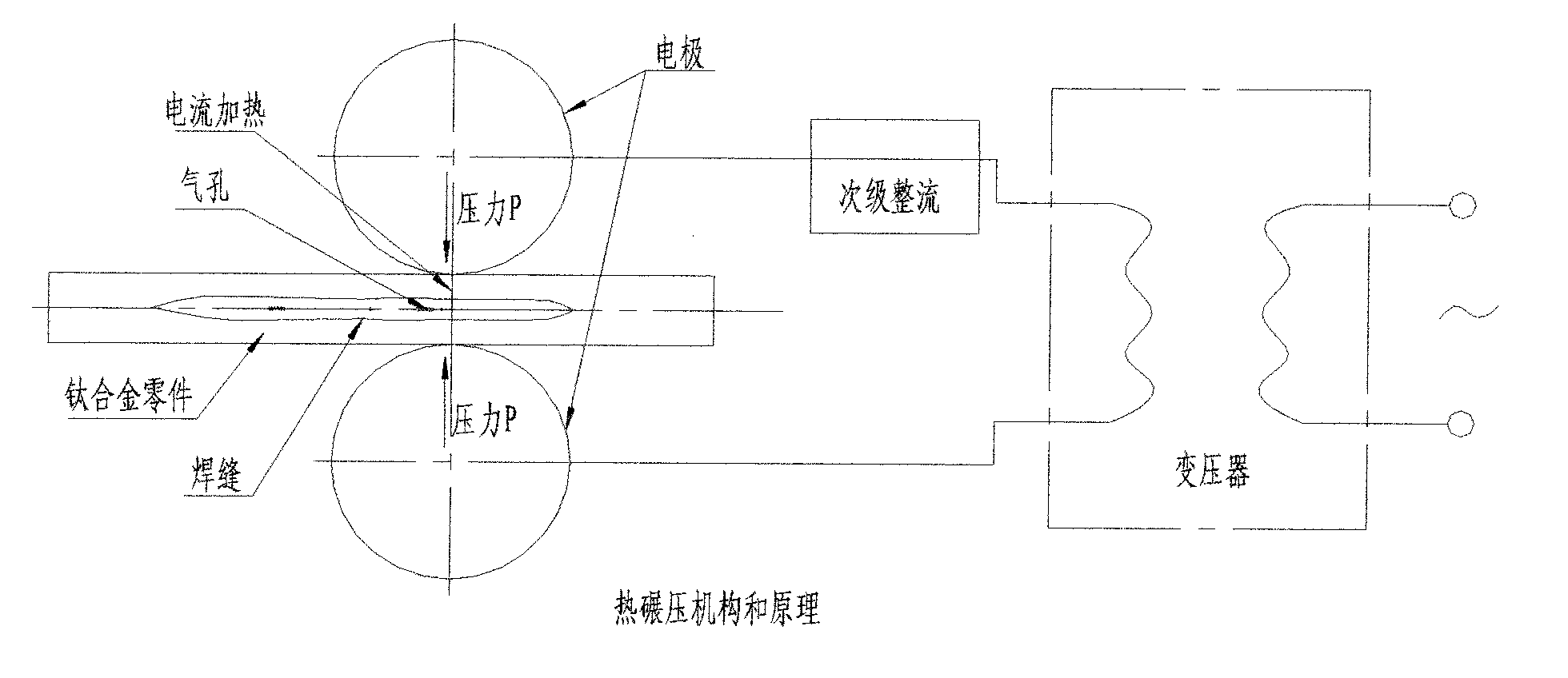

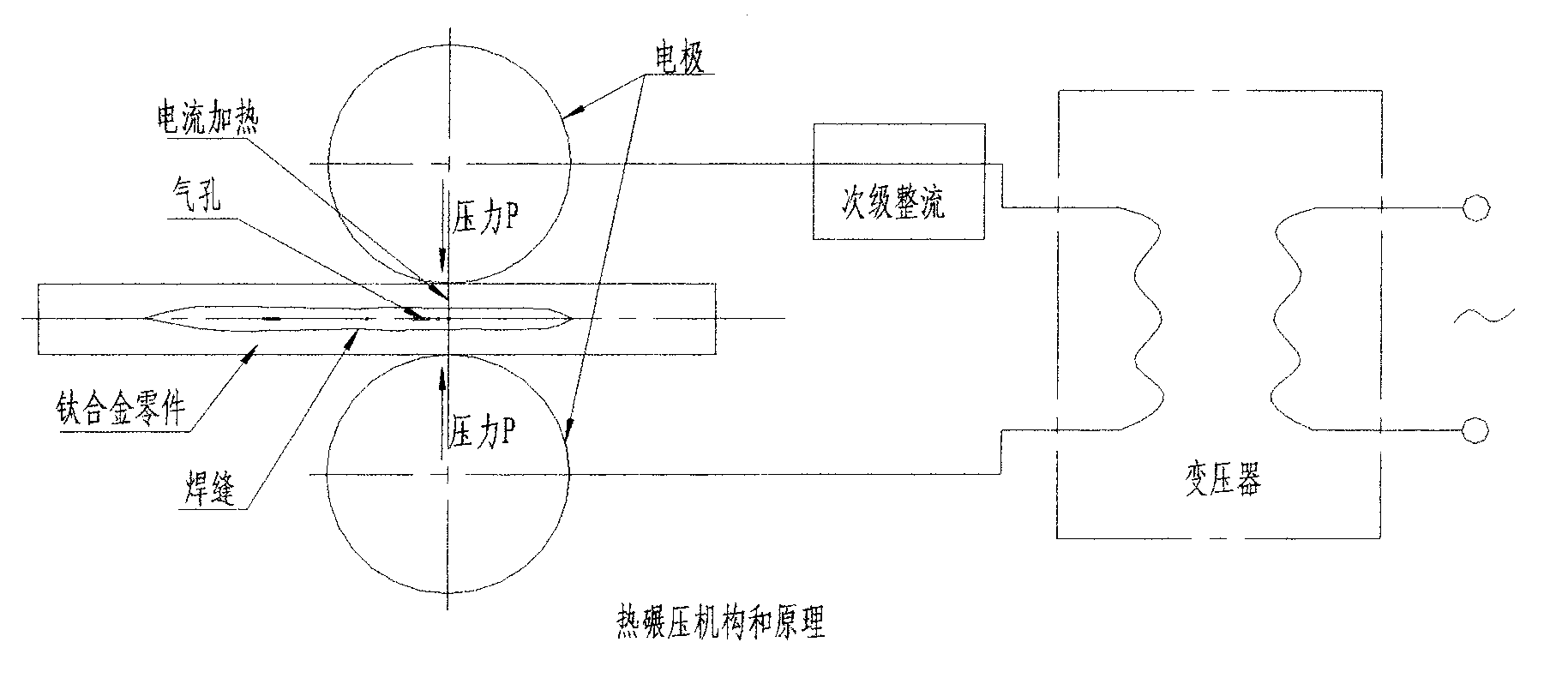

[0057] A method for hot rolling to repair the pores of welded seams of titanium alloy thin plates, which uses the principle of resistance welding and the resistance welding characteristics of the parts themselves to perform hot rolling operations; specifically, the method of rolling welding is used to weld metal The process of applying pressure and heating to eliminate pores.

[0058] The method for hot rolling repairing the pore defect of titanium alloy thin plate fusion welding seam described in this embodiment also includes the following content description:

[0059] In the method of hot rolling repairing the pore defect of titanium alloy thin plate fusion welding seam, before the hot rolling repair operation, the welding test piece is used to carry out the hot rolling test so as to select the appropriate parameters of pressure, current and energization time; The welding test piece is specifically the test piece with the same material and thickness as the part to be repaire...

Embodiment 2

[0073] The content of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0074] The hot rolling method for repairing the pore defect of titanium alloy thin plate fusion welding seam is aimed at the special resistance welding fixture: columnar electrode, using the following specific operation method of hot rolling:

[0075] Place the weld defect to be repaired on the processed part between two columnar electrodes, apply pressure and energize according to the same parameters of the test to remelt the pores inside the weld.

[0076] While using the above two specific operation schemes, it is also required to carry out small current cladding repair operation on the deep indentation on the surface of the processed part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com