Process for preparing microcrystal glass-ceramic compounded plate

A glass-ceramic and ceramic composite technology, which is applied in the field of preparation of glass-ceramic-ceramic composite boards, can solve problems such as pore defects and single texture, and achieve low porosity, elegant taste, and natural and unique decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

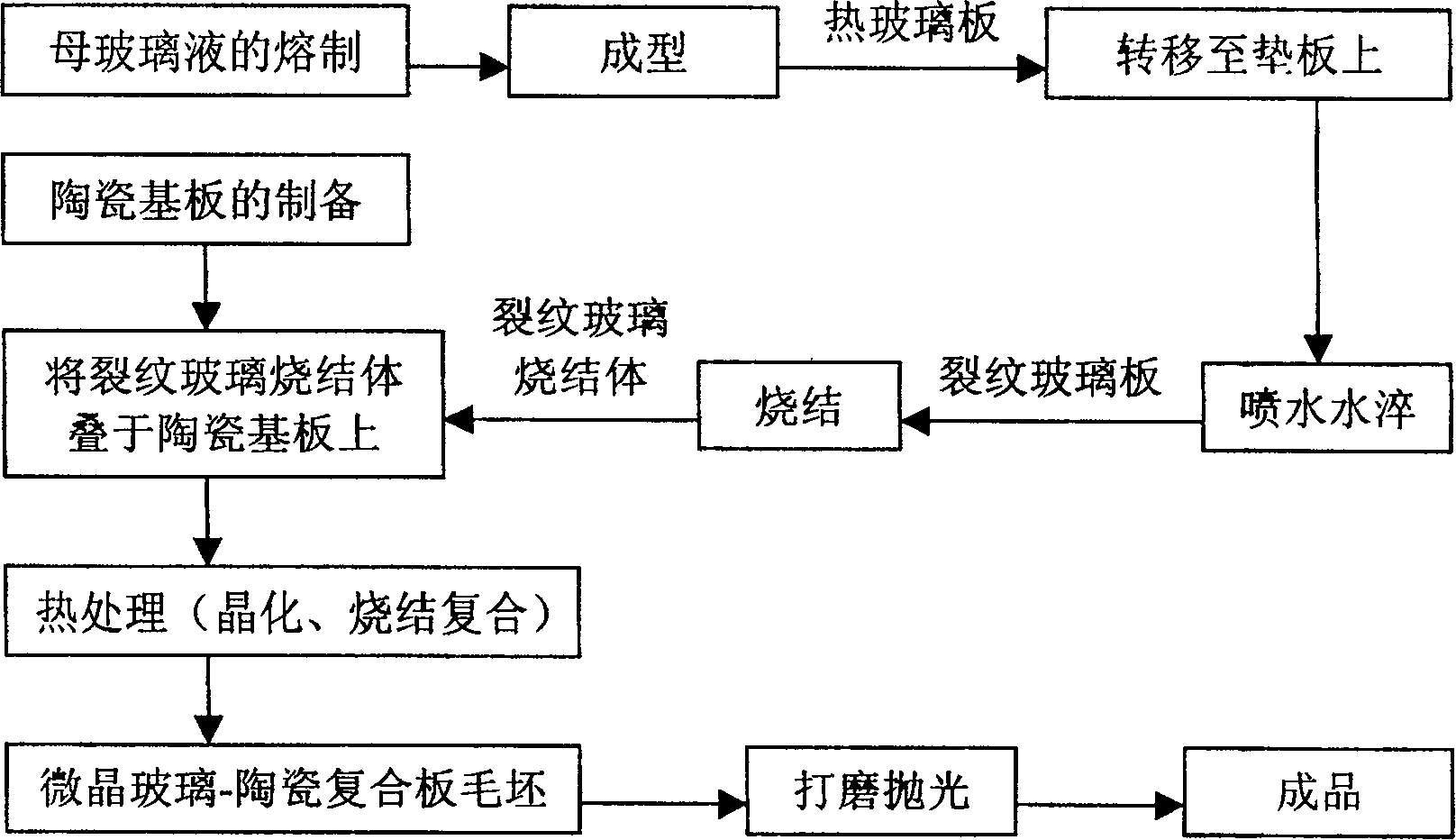

[0038] A preparation method of glass-ceramic-ceramic composite plate, such as figure 1 As shown, it includes the following steps:

[0039] 1) Preparation of ceramic substrate: use conventional ceramic raw materials, raw material ratio (expressed in mass percentage, the same in the following examples) is: 39.0% feldspar, 13%.0 quartz, 45.0% clay, 3.0% talc, raw material mixing The chemical composition of the material (expressed in mass percent, the same in the following examples) is: 67.90% SiO 2 , 19.50%Al 2 o 3 , 0.50% CaO, 0.90% MgO, 1.50% K 2 O; 2.50% Na 2 O, 0.40%TFe 2 o 3 , 0.10%TiO 2 , loss on ignition 6.40%, and other ingredients 0.30%; each raw material is weighed according to the formula, put into a ball mill, and wet ball milled to a particle size of 4% over a million-hole sieve; spray-dried to make materials, and the moisture content of the powder is 7%; The ceramic brick press is pressed and formed, and dried in a drying kiln to obtain a dry ceramic green b...

Embodiment 2

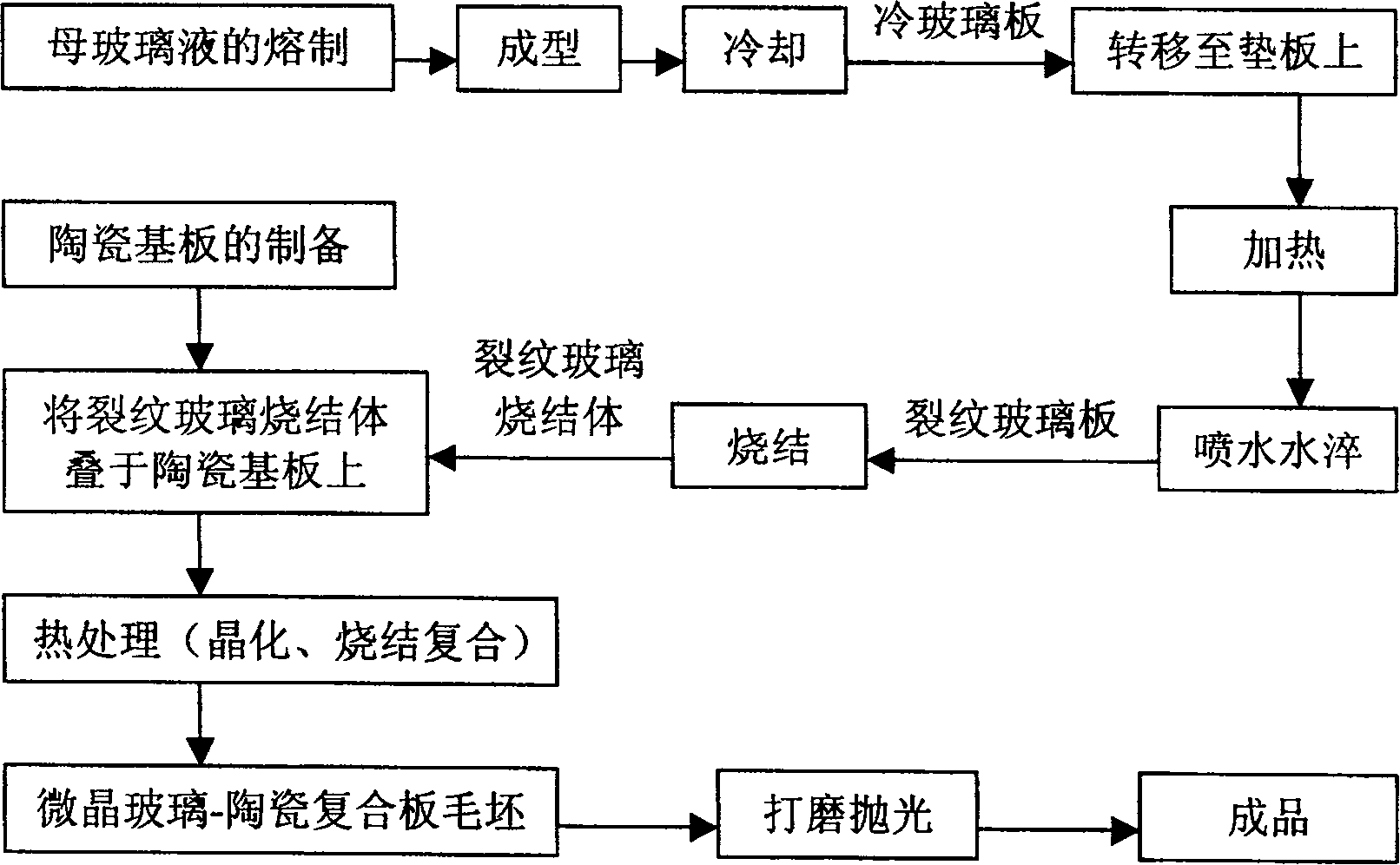

[0045] A preparation method of glass-ceramic-ceramic composite plate, such as figure 2 As shown, it includes the following steps:

[0046] 1) Preparation of ceramic substrates: using conventional ceramic raw materials, the raw material ratio is: 39.0% feldspar, 13.0% quartz, 45.0% clay, 3.0% talc, the chemical composition of the raw material mixture is: 67.90% SiO 2 , 19.50%Al 2 o 3 , 0.50% CaO, 0.90% MgO, 1.50% K 2 O; 2.50% Na 2 O, 0.40%TFe 2 o 3 , 0.10%TiO 2 , loss on ignition 6.40%, and other ingredients 0.30%; each raw material is weighed according to the formula, put into a ball mill, and wet ball milled to a particle size of 4% over a million-hole sieve; spray-dried to make materials, and the moisture content of the powder is 7%; The ceramic brick press is pressed into shape, and dried in a drying kiln; the dried ceramic green body is kept at 1210°C for 20 minutes, and fired into a ceramic green body, which is used as a ceramic substrate for later use;

[0047] ...

Embodiment 3

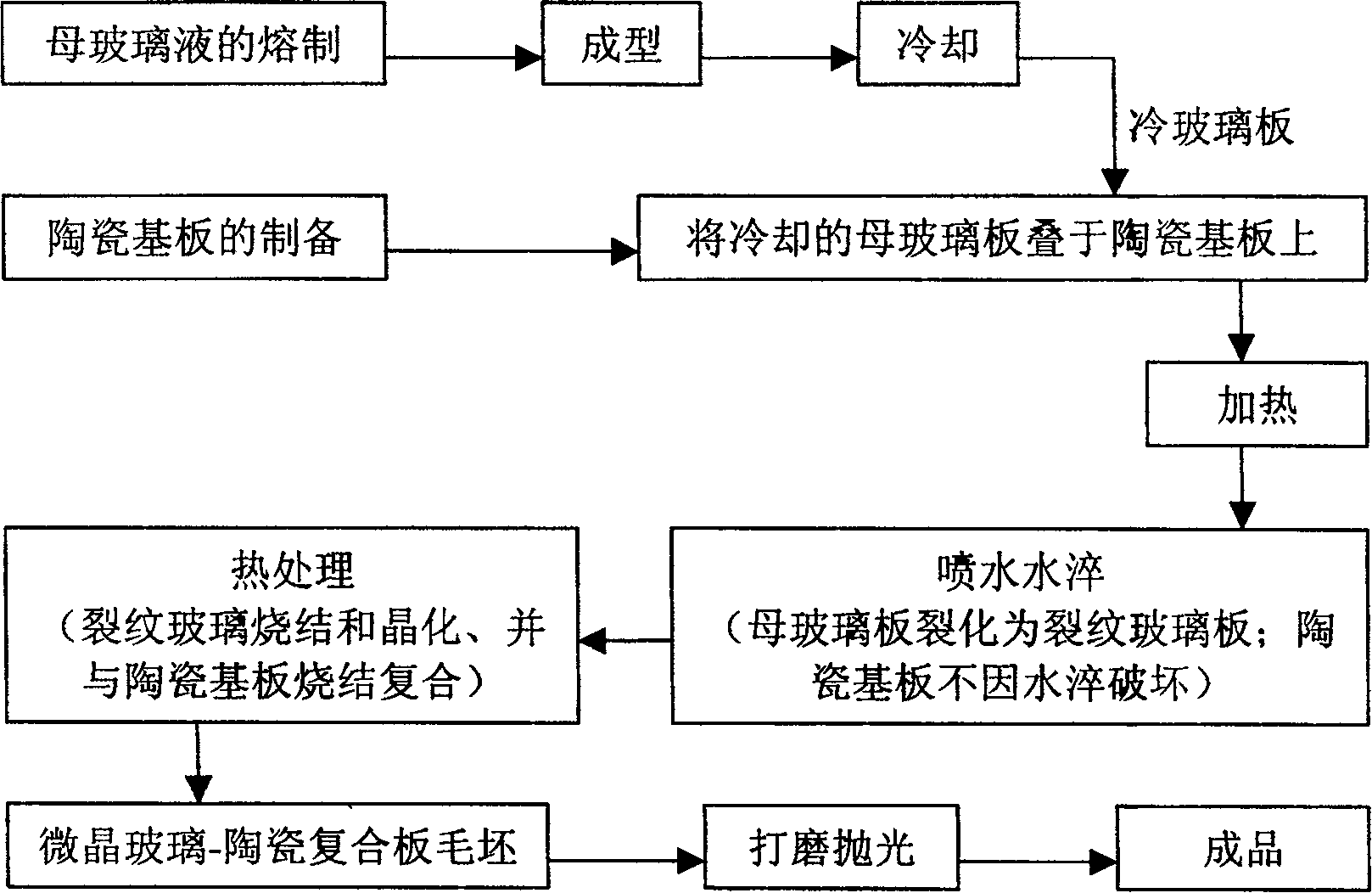

[0051] A preparation method of glass-ceramic-ceramic composite plate, such as image 3 As shown, it includes the following steps:

[0052] 1) Preparation of ceramic substrates: using conventional ceramic raw materials, the raw material ratio is: 39.0% feldspar, 13%.0 quartz, 45.0% clay, 3.0% talc, the chemical composition of the raw material mixture is: 67.90% SiO 2 , 19.50%Al 2 o 3 , 0.50% CaO, 0.90% MgO, 1.50% K 2 O; 2.50% Na 2 O, 0.40%TFe 2 o 3 , 0.10%TiO 2 , loss on ignition 6.40%, and other ingredients 0.30%; each raw material is weighed according to the formula, put into a ball mill, and wet ball milled to a particle size of 4% over a million-hole sieve; spray-dried to make materials, and the moisture content of the powder is 7%; The ceramic brick press is pressed into shape, and dried in a drying kiln; the dried ceramic green body is kept at 1210°C for 20 minutes, and fired into a ceramic green body, which is used as a ceramic substrate for later use;

[0053] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com