Method for preparing micro crystal glass-ceramic composite board by employing whole glass board as mother glass

A technology of glass-ceramics and glass plates, which is applied in the field of preparation of glass-ceramic-ceramic composite plates, can solve the problems of high raw material cost, complex production process, and prone to pore defects, etc., and achieve simple production process, low raw material cost, Low total cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

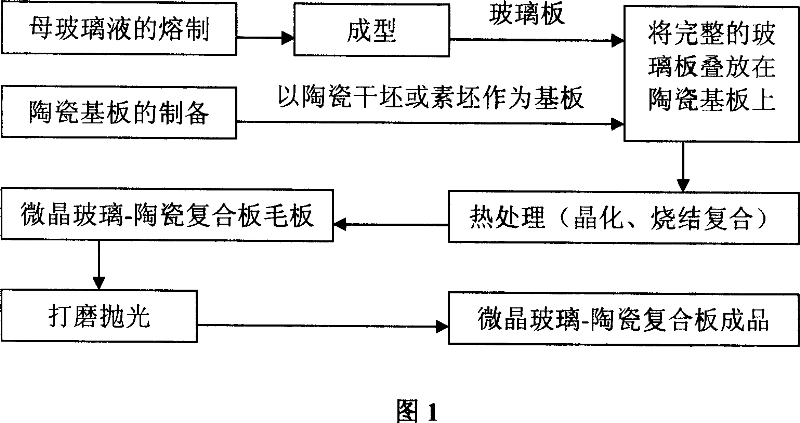

[0029] Prepare the method for glass-ceramic-ceramic composite plate as mother glass with complete glass plate, as shown in Figure 1, it comprises the steps:

[0030] 1) Preparation of ceramic substrate: use conventional ceramic raw materials, raw material ratio (expressed in mass percentage, the same in the following examples) is: 39.0% feldspar, 13.0% quartz sand, 45.0% clay, 3.0% talc, raw material mixing The chemical composition of material (expressed in mass percent, the same in the following examples) is: 67.50% SiO 2 , 19.90%Al 2 o 3 , 0.40% CaO, 0.80% MgO, 1.70% K 2 O; 2.60% Na 2 O, 0.40%TFe 2 o 3 , 0.10%TiO 2 , loss on ignition 6.30%, and other 0.30%; each raw material is weighed according to the formula, put into a ball mill, and wet ball milled until the particle size is 4% of the remaining 4% of the million-hole sieve; spray drying granulation, the powder moisture is 7%; the powder is passed through The ceramic brick press is pressed and formed, and dried in ...

Embodiment 2

[0035] Prepare the method for glass-ceramic-ceramic composite plate as mother glass with complete glass plate, as shown in Figure 1, it comprises the steps:

[0036] 1) Preparation of ceramic substrates: using conventional ceramic raw materials, the raw material ratio is: 39.0% feldspar, 13.0% quartz sand, 45.0% clay, 3.0% talc, the chemical composition of the raw material mixture is: 67.50% SiO 2 , 19.90%Al 2 o 3 , 0.40% CaO, 0.80% MgO, 1.70% K 2 O; 2.60% Na 2 O, 0.40%TFe 2 o 3 , 0.10%TiO 2 , loss on ignition 6.30%, and other 0.30%; each raw material is weighed according to the formula, put into a ball mill, and wet ball milled until the particle size is 4% of the remaining 4% of the million-hole sieve; spray drying granulation, the powder moisture is 7%; the powder is passed through The ceramic brick press is pressed and formed, and dried in a drying kiln to obtain a ceramic dry body; the dry body is entered into a roller kiln, and is kept at 1200°C for 30 minutes unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com