Robot assembly line for LED backlight module

An assembly line and backlight module technology, applied in assembly machines, manipulators, program-controlled manipulators, etc., can solve the problems of reduced production efficiency, low precision, light leakage, etc., achieve high assembly efficiency, improve yield rate, and reduce quality loss rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

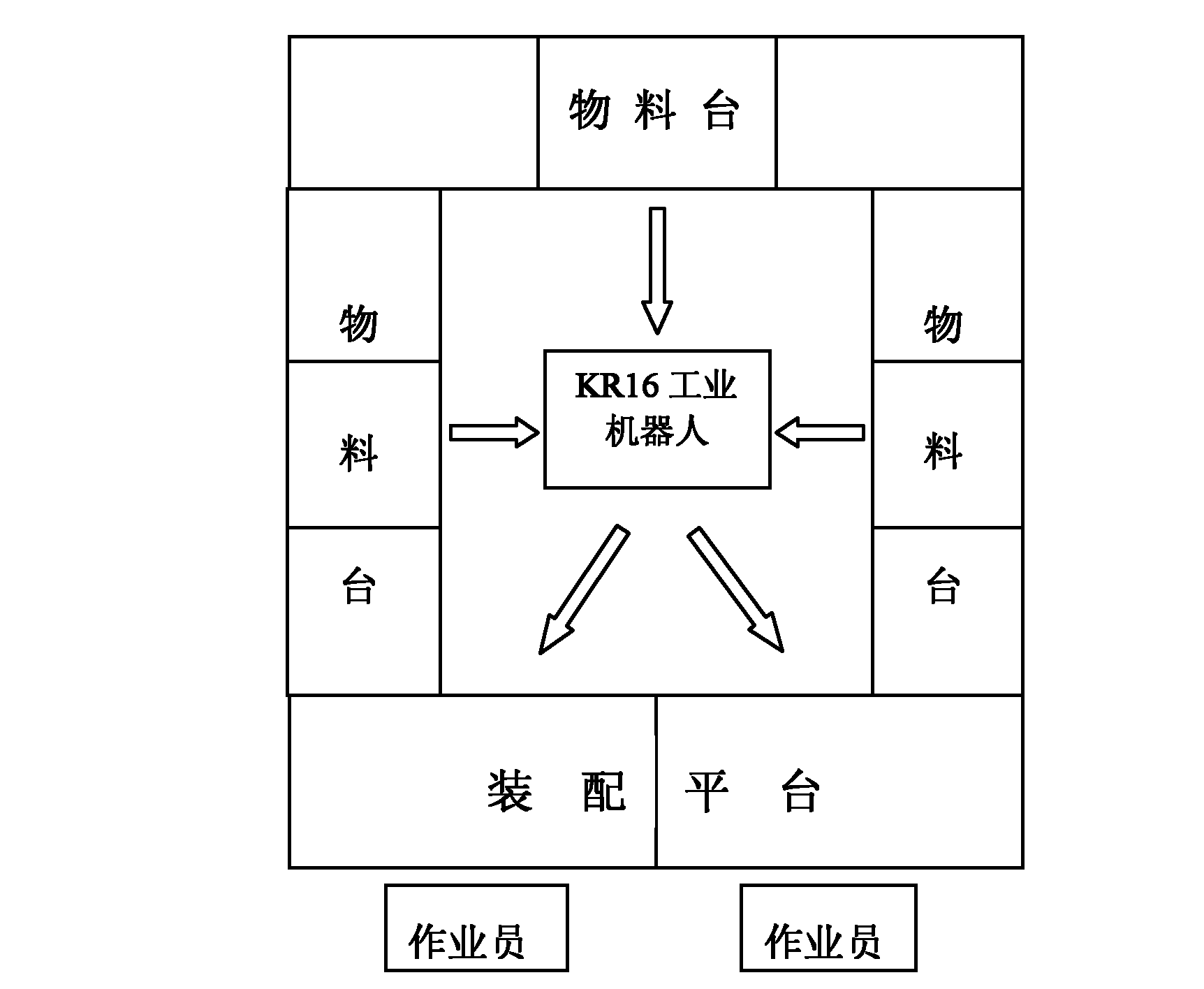

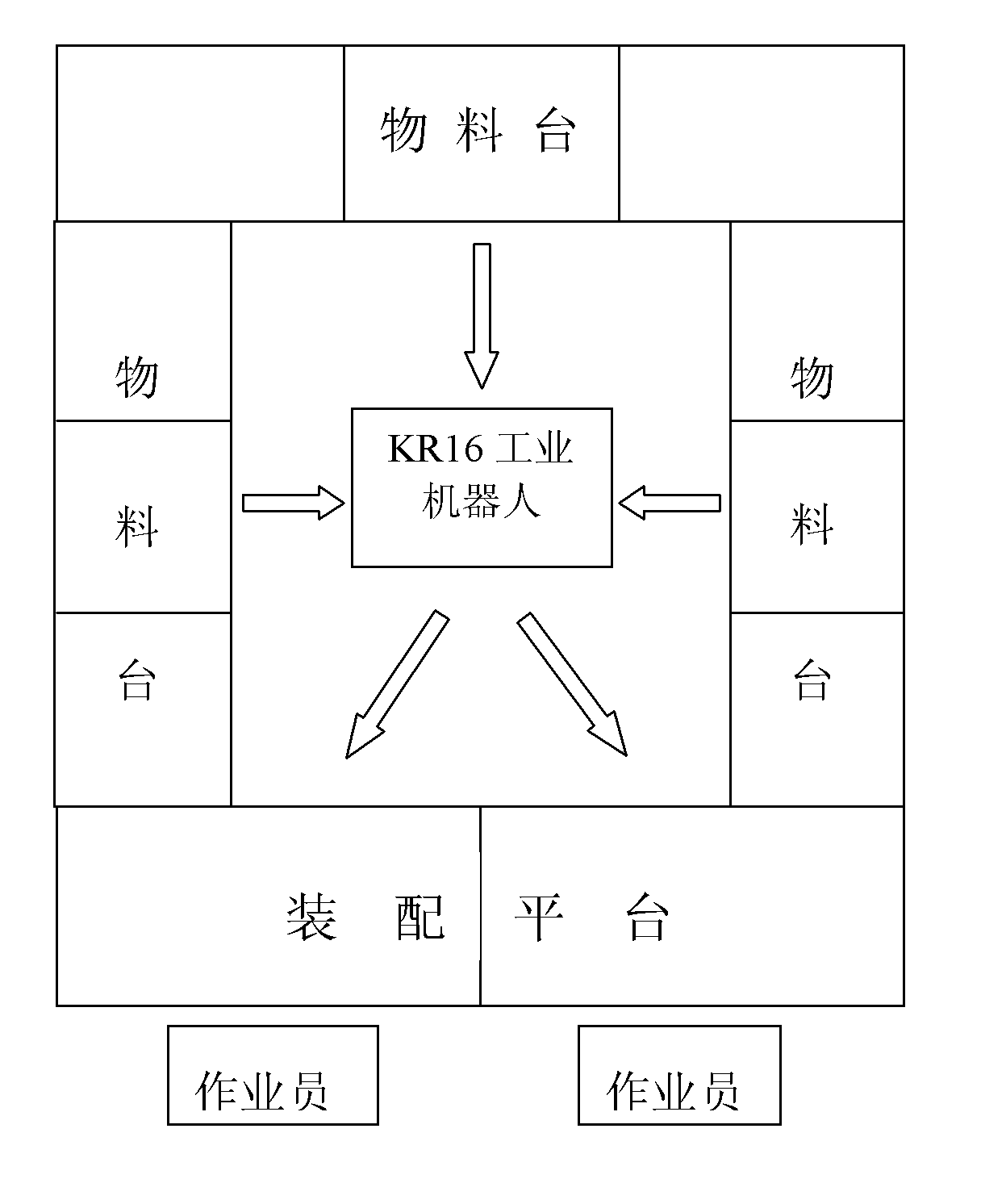

[0007] The invention includes German KUKA KR16 industrial robot, robot gripper, robot gripper automatic identification device, assembly platform, material platform, electrical control device, safety device, the robot gripper is connected with the arm of the KR16 industrial robot, and the robot uses the gripper to adopt Piab vacuum suction method extracts raw materials, a square platform surrounds the robot, 3 sides of which are material platforms, and each material platform can accommodate 3 small platforms for loading raw materials, and each small platform can be manually adjusted to position raw materials; The other side of the square platform is the assembly platform. There are suction cups on the assembly platform, which can fix the backplane in a good position. The robot grabs the materials on the material table through the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com