High polymer grouting directional cleaving drilling tool and pore forming method

A technology of high polymer and drilling tools, which is applied in the field of water conservancy infrastructure and reinforcement, can solve problems such as large difference in stiffness, large damage to dam body structure, and uncoordinated deformation, and achieves good directional guidance effect, broad social benefits, and dams. little perturbation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

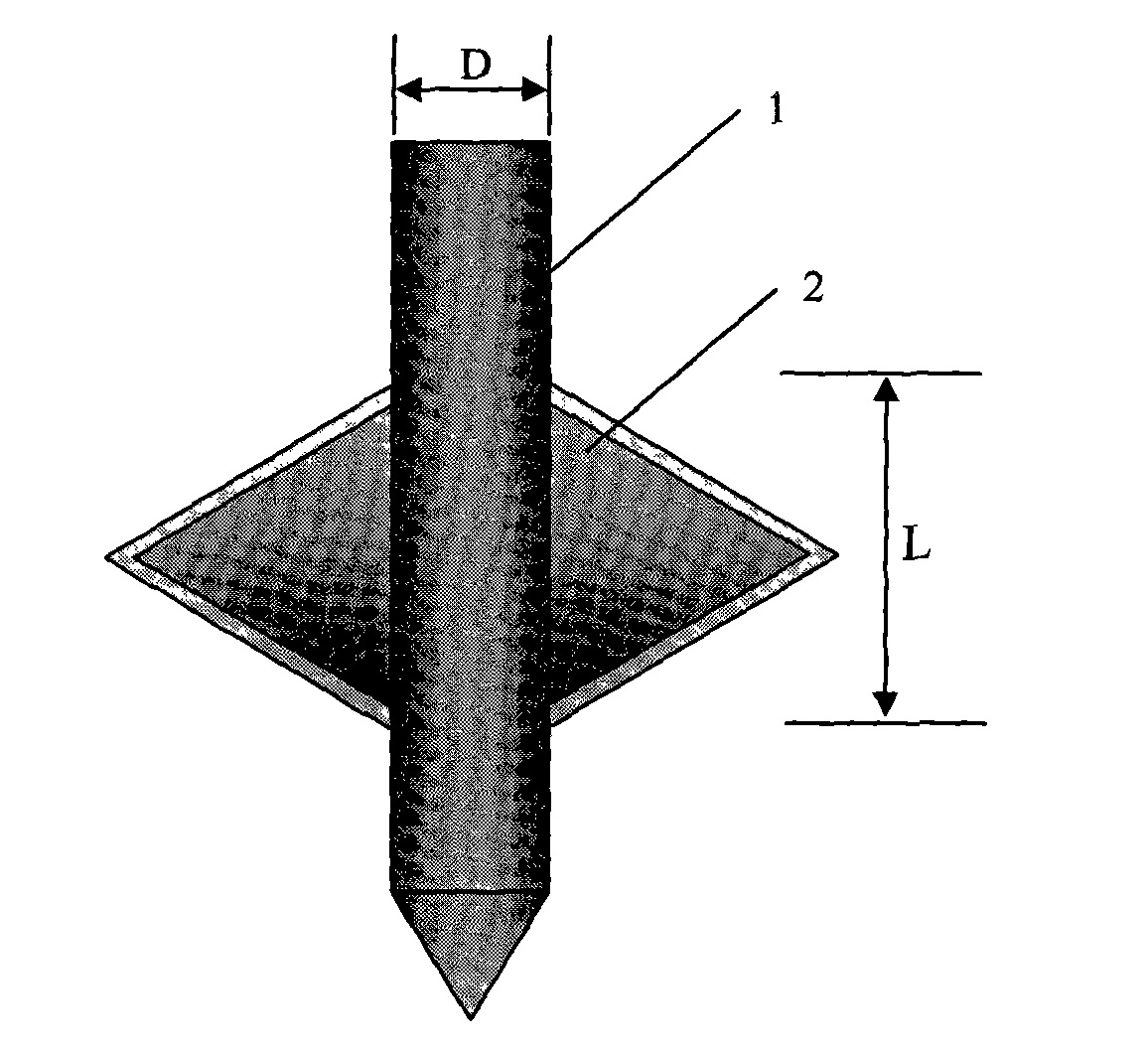

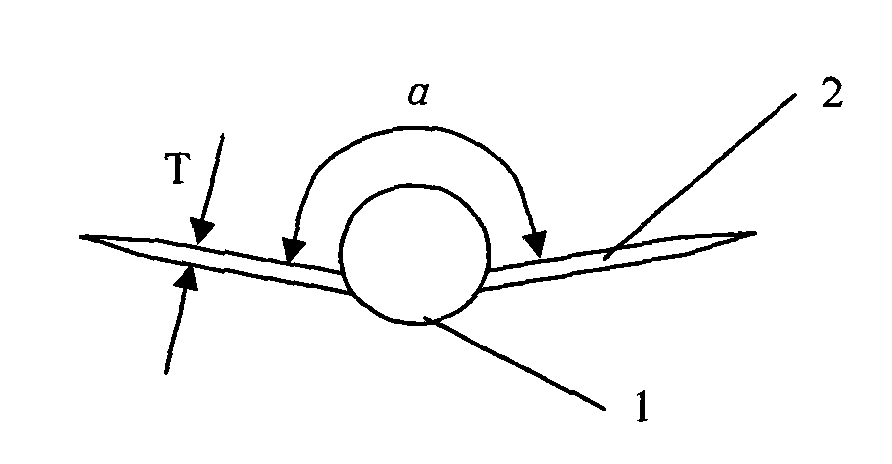

[0031] Embodiment: The polymer grouting directional splitting drilling tool of the present invention is a double-wing drilling tool, that is, a triangular wing 2 is welded on both sides of the circular drilling rod 1; the diameter D of the circular drilling rod 1 is 40-50mm , the cone angle at the end of the circular drill rod 1 is 30-60 degrees; the wings 2 on both sides of the circular drill rod 1 are symmetrically welded triangular steel plates with cutting edges, the thickness is 5-10mm, and the side length is L is 60-80mm; the angle α between the two wings 2 is 140-160 degrees.

[0032] The specific size of the polymer grouting directional splitting drilling tool can be adjusted appropriately according to the characteristics of the soil.

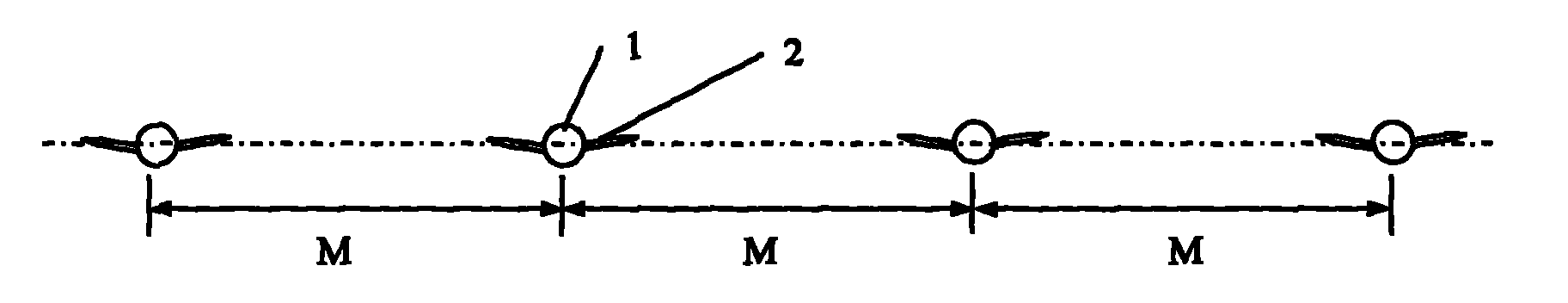

[0033] The polymer grouting directional splitting hole forming method is to use the polymer grouting directional splitting drilling tool, and use the static penetration testing principle to press the polymer grouting directional splitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com