Exhaust hood assembly for outdoor gas water heater

A technology for gas water heaters and exhaust hoods, applied in the field of exhaust hoods, which can solve problems such as interference with the flame combustion state, machine damage, and failure to work normally, and achieve the effect of improving the drag coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

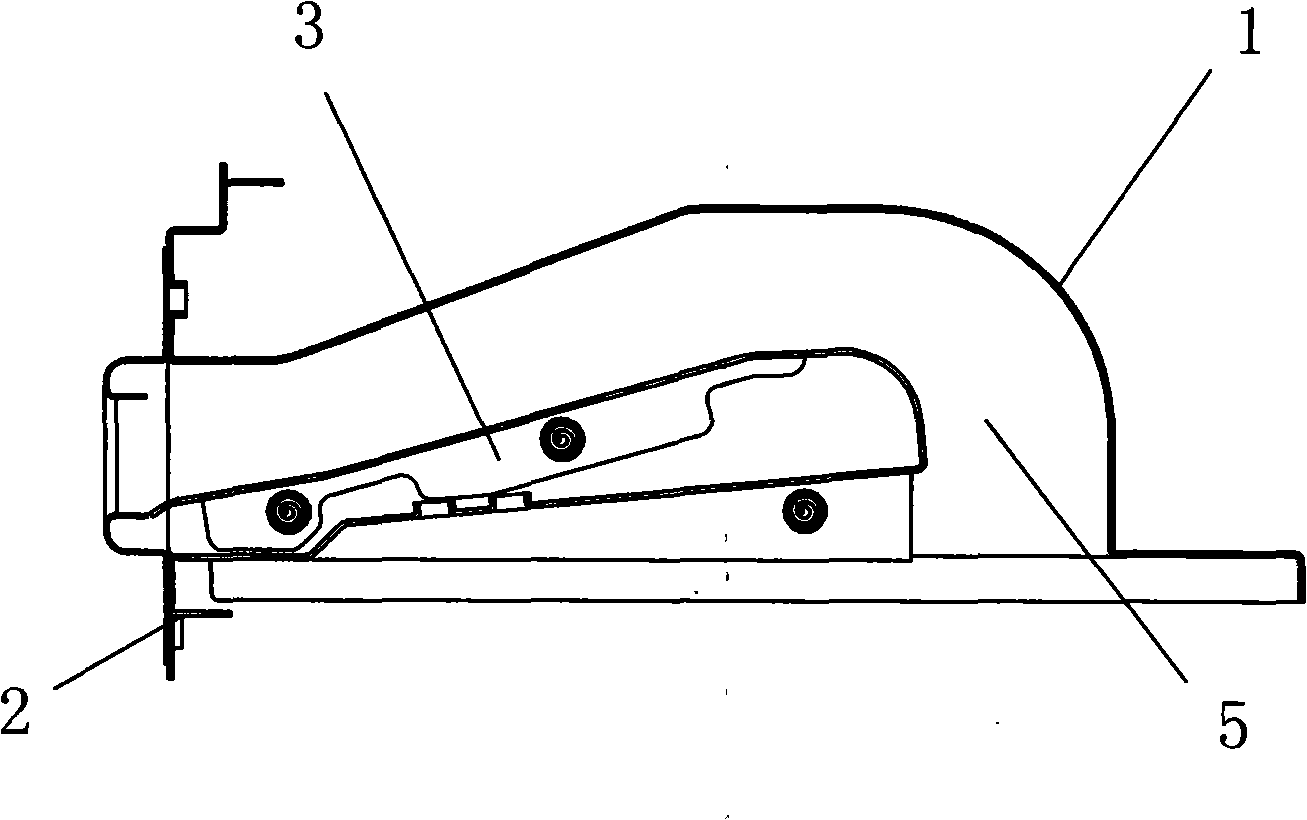

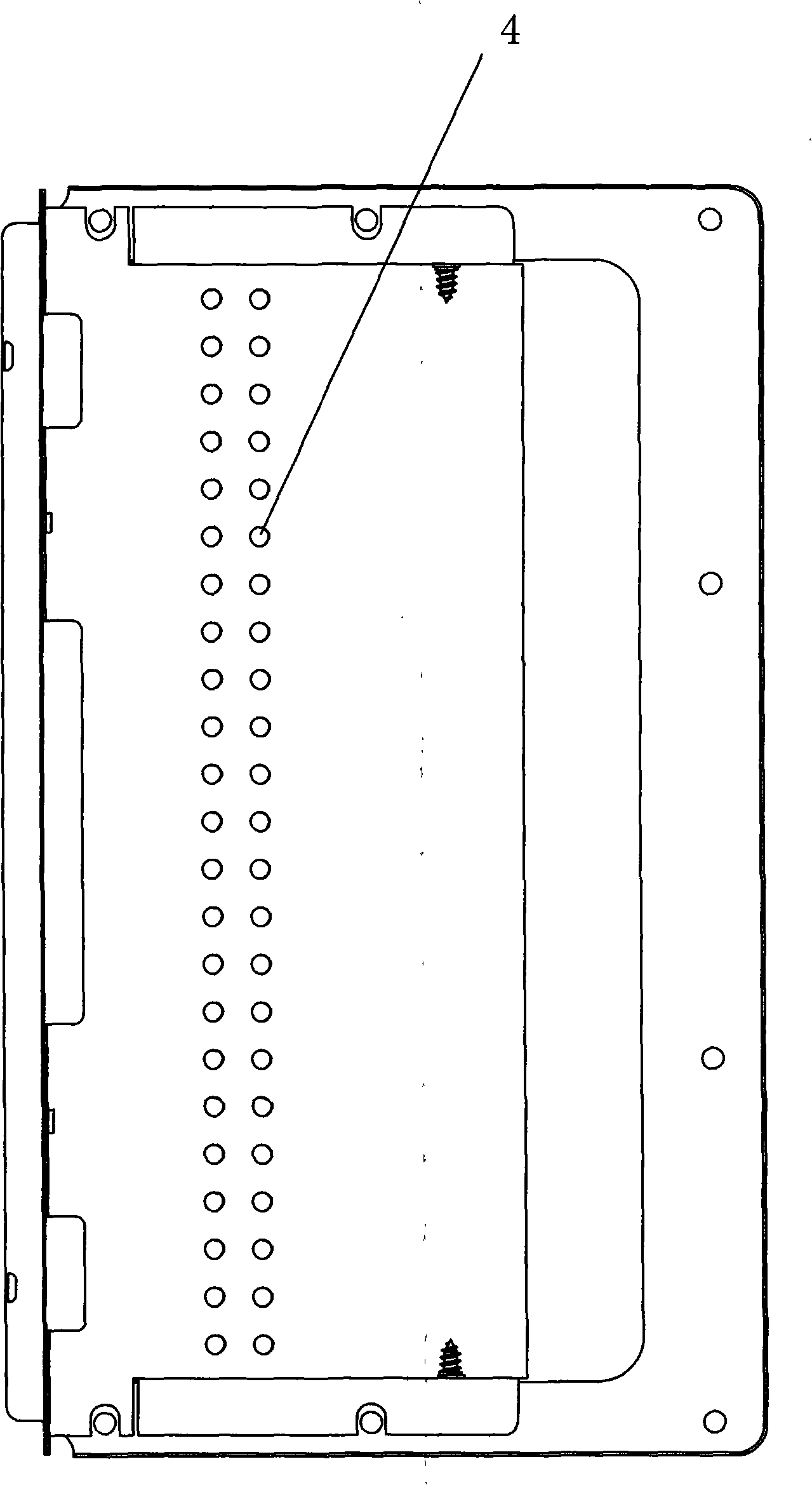

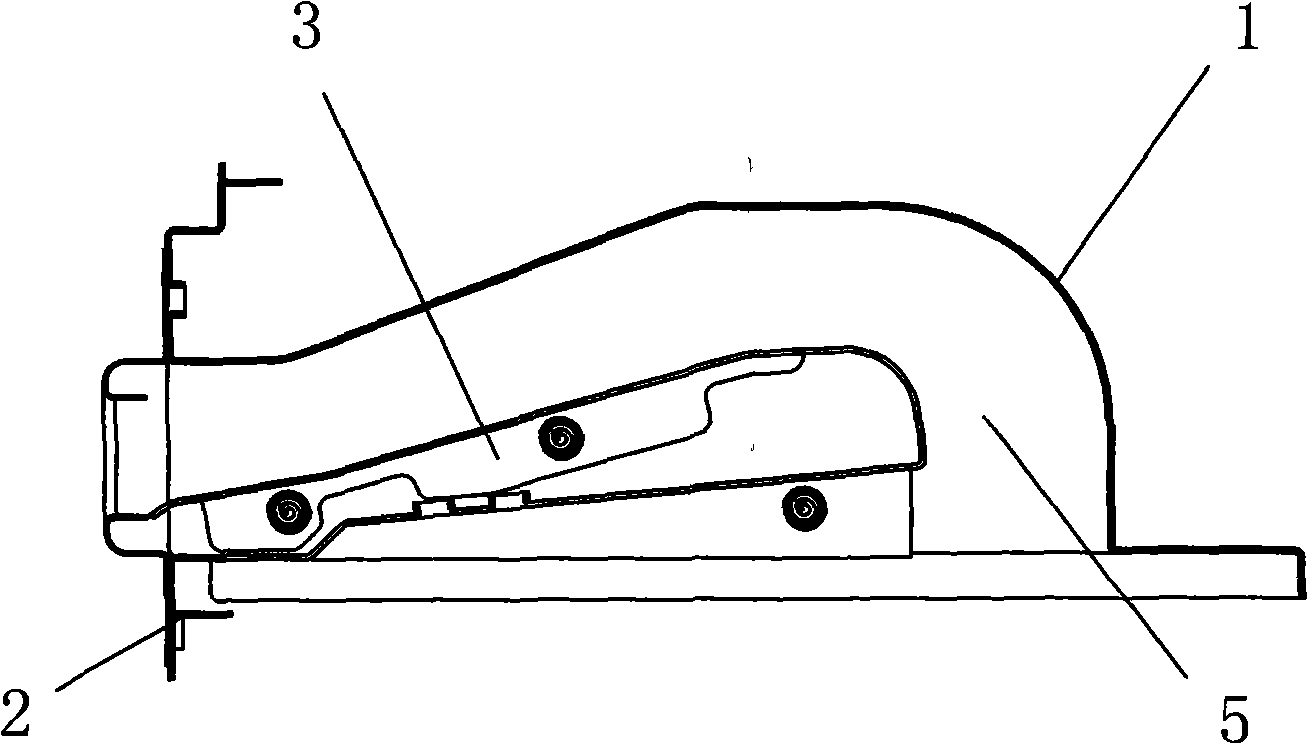

[0012] Embodiment: An exhaust hood combination for an outdoor gas water heater, the exhaust hood combination includes a diversion shell 1, an inner tank 2 and an outlet piece 3, the outlet piece 3 is fixed on the wall, and is based on the installation and use direction of the water heater. The diversion shell 1 has an open side and a smoke inlet on the bottom surface, the top surface and the remaining sides of the diversion shell 1 are closed surfaces, the diversion shell 1 is sleeved outside the inner tank 2, and the diversion shell 1. The inner side of the top inner side and the inner side of the diversion shell 1 on the opposite side to the open side respectively form a smoke flow channel from the bottom to the open side of the shell with the upper surface of the inner tank 2 and the outer side of the inner tank 2 opposite to the open side of the shell. 5. The lower end of the smoke flow channel 5 is connected to the smoke inlet on the bottom surface of the shell, the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com