Filling component for gas-liquid contact and cooling tower using filling component for gas-liquid contact

A gas-liquid contact and cooling tower technology, applied in the direction of water shower coolers, direct contact heat exchangers, climate sustainability, etc., can solve the problem of unbalanced water film thickness and flowing speed, cooling water dripping, and impossibility Captures problems such as scattered water to achieve space saving, price reduction, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

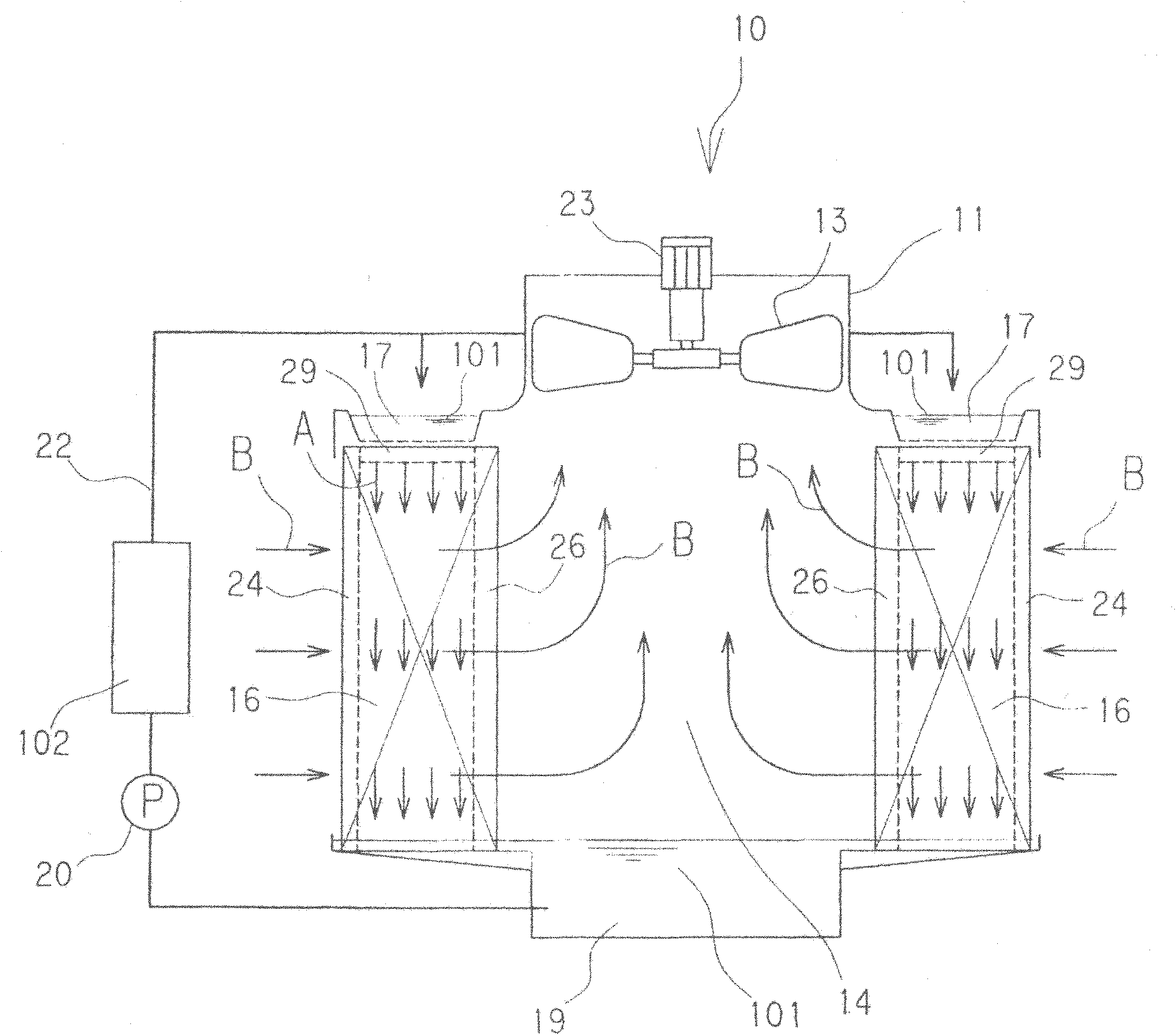

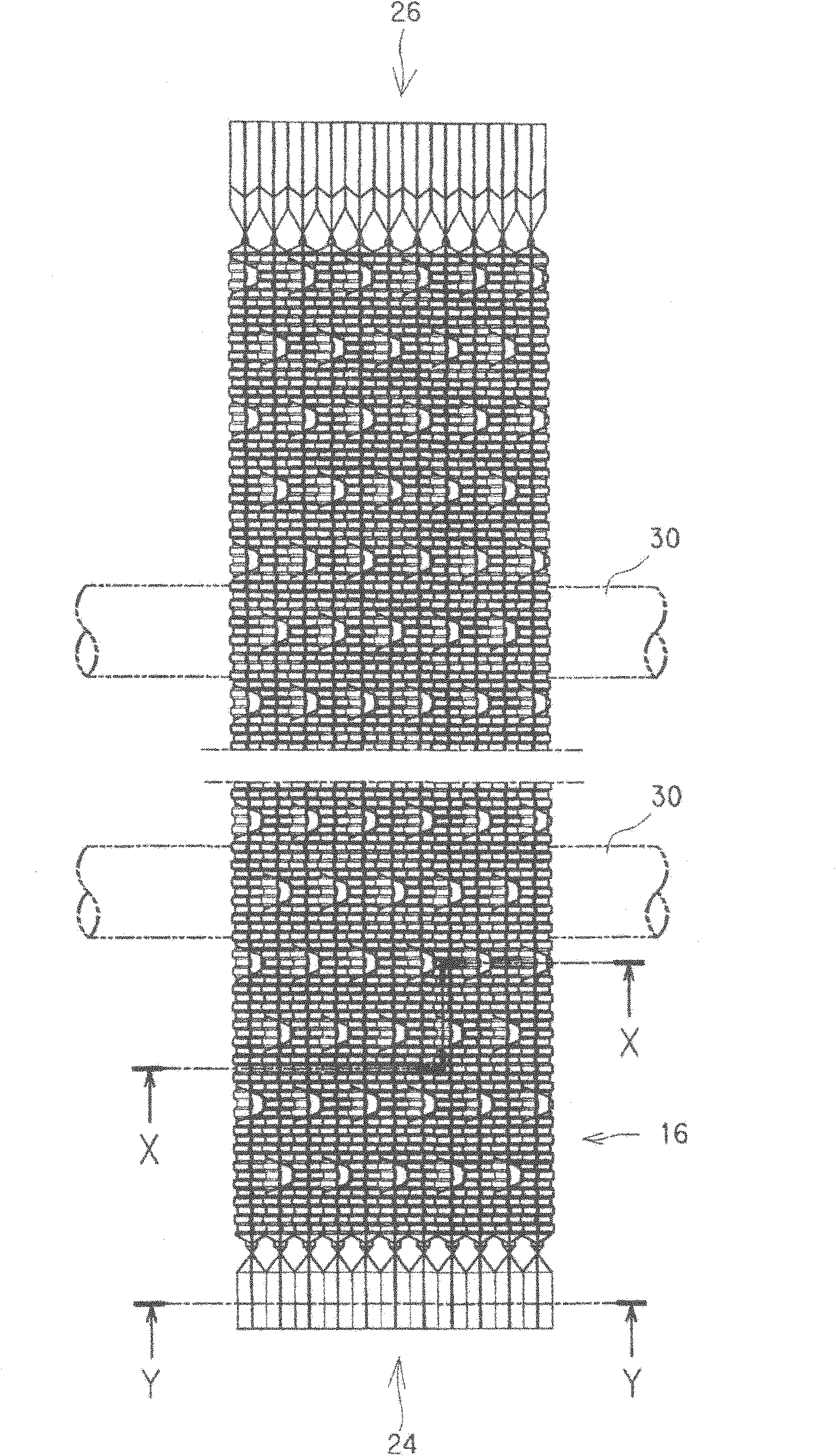

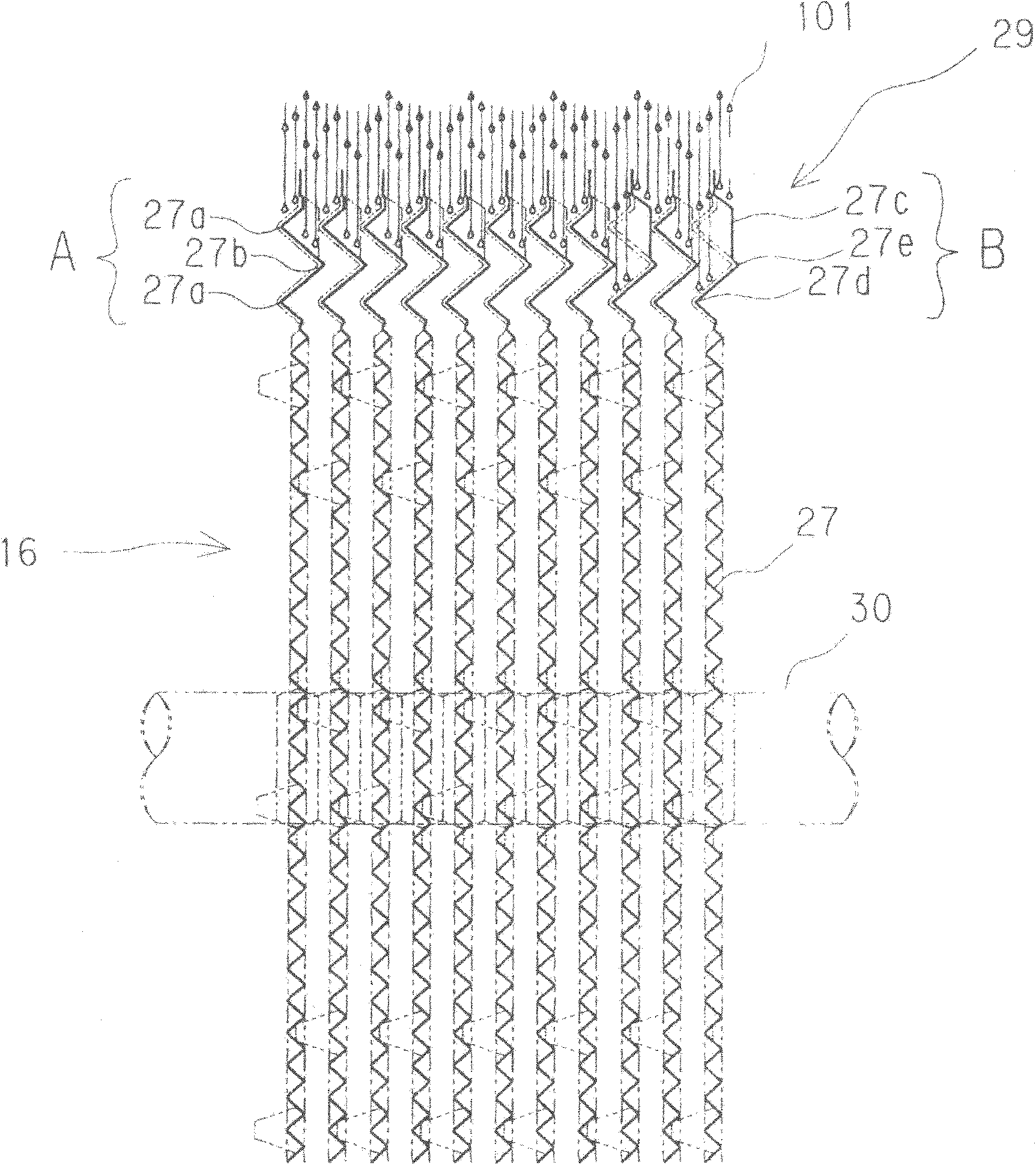

[0054] Embodiments of the present invention will be described in detail below. figure 1 It is a figure which shows the schematic structure of the cooling tower which concerns on one Embodiment of this invention. The cooling tower 10 is provided with a cooling tower frame 11 , and a fan 13 is arranged at an upper central portion in the cooling tower block diagram 11 . The central portion of the cooling tower frame 11 serves as an external air passage 14 through which external air flows. In the cooling tower frame 11 , on both sides of the external air passage 14 , filling members 16 , 16 for gas-liquid contact are arranged. Water sprinkling tanks 17, 17 are respectively arranged on the upper parts of the filling members 16, 16 for external air contact. In the bottom of the sprinkler tank 17, a plurality of holes for sprinkler water are formed.

[0055] The cooling water 101 in the water spray tank 17 is sprayed on the top of the filling member 16 for gas-liquid contact throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com