Spot simulation device for fault oil product of transformer

A transformer failure and simulation device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of no mature method, the inability to judge the operating conditions and data accuracy of online chromatographs, and achieve strong practicability and control Sensitive and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

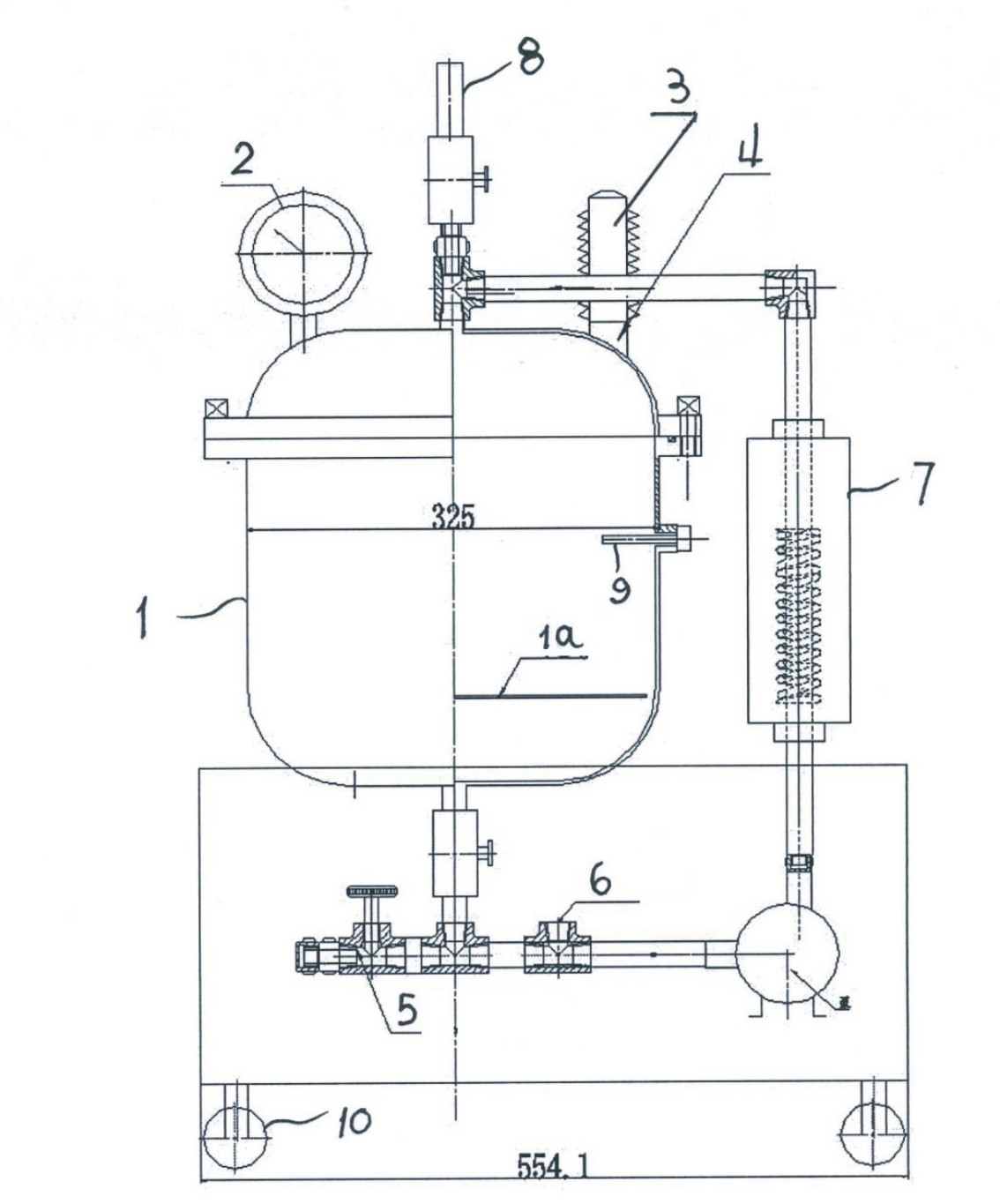

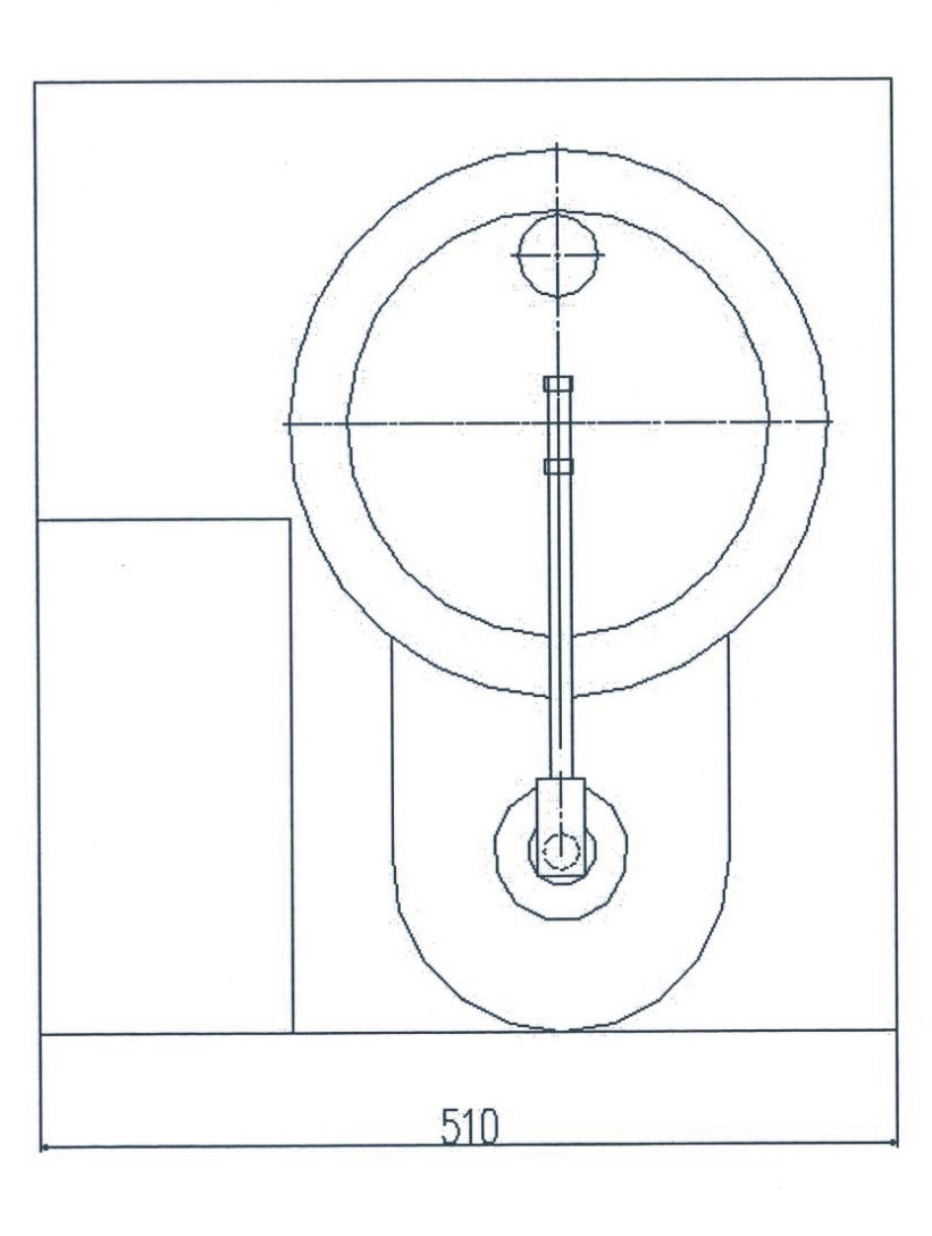

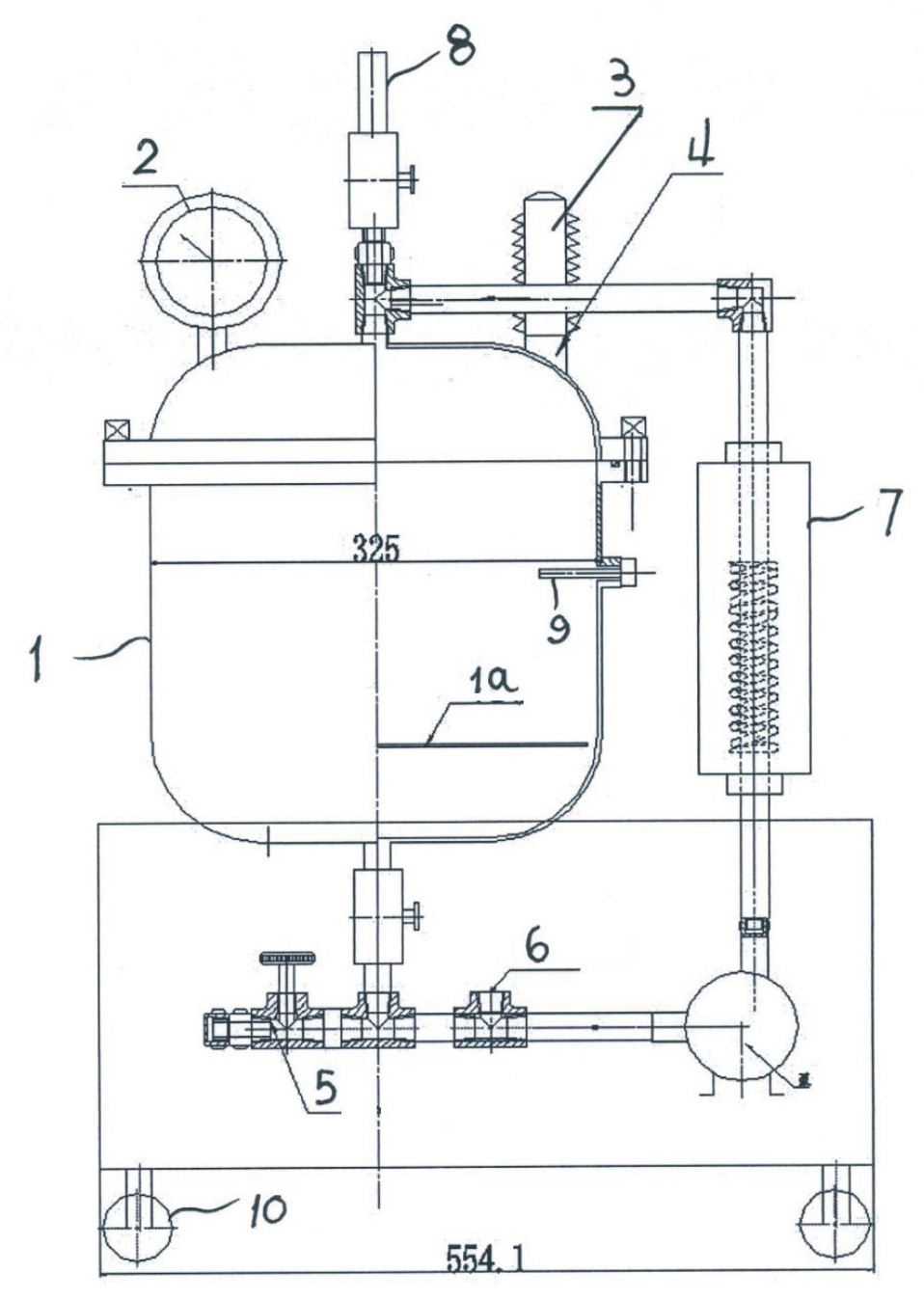

[0030] figure 1 , figure 2 As shown, the present invention includes a temperature control system composed of an electric heater, a piston expander, and an electrode point pressure gauge 2 is arranged on the top of the oil storage tank 1, and the electrodes of the electrode point pressure gauge 2 are connected to the power supply circuit of the heater Above, the electric heater is set in the oil storage tank and / or on the upper pipeline of the oil storage tank, a temperature sensor 9 is arranged on the side wall of the oil storage tank, and a circulating pump is arranged between the upper pipeline of the oil storage tank and the bottom pipeline of the oil storage tank 7. The upper pipeline of the oil storage tank is equipped with a transformer oil sampling port 8, and the bottom pipeline of the oil storage tank is equipped with a standard gas sampling port 6 and a sampling tube. The sampling tube is equipped with a sampling valve 5; The top of the oil storage tank is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com