Preparation method of anode material for lithium-ion battery prepared by anthracite

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high preparation cost of graphite-based negative electrode materials, uneven SEI film, and insufficient bonding, and achieve high and low temperature resistance. , low thermal expansion coefficient and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

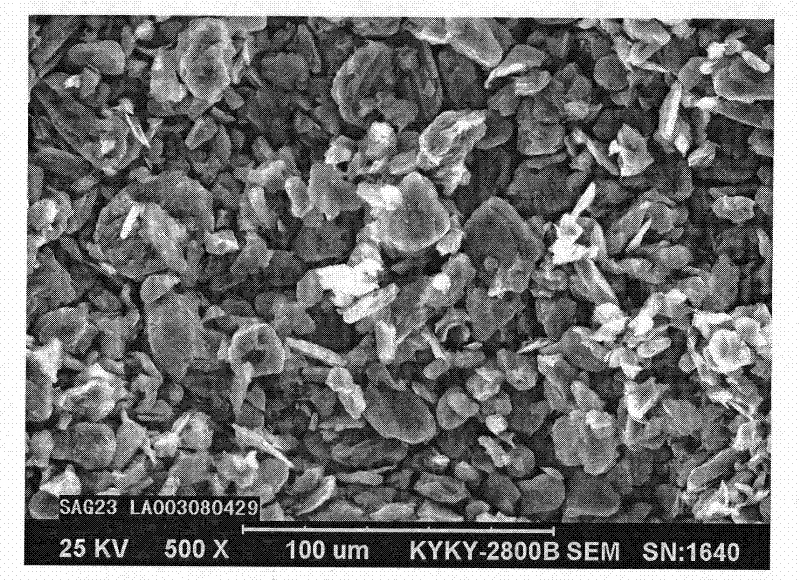

[0033] A lithium-ion battery negative electrode material prepared from anthracite, its particle size distribution D10 is 6-10 μm, D50 is 17-20 μm, D90 is 28-50 μm, and its tap density is 0.9 g / cm 3 , the carbon content is 97%, and the degree of graphitization is 87%.

[0034] A method for preparing aphanitic graphite negative electrode materials for lithium-ion batteries from anthracite, comprising the steps of:

[0035] (1) Select the anthracite whose Vdaf% is 0-7.5, Hdaf% is 0-4, the average maximum reflectance of vitrinite is higher than 6%, and the dry ash-free base high calorific value is lower than 22% MJ / KG. Crushed and classified by ball mill, the particle size distribution D50 is 0-30mm, and the tap density is 0.8g / cm 3 powdered anthracite precursor, and then with a density of 1g / cm 3 The mixture of magnetite powder and water is dense medium coal preparation, which washes out anthracite with a carbon content of more than 93%, a calorific value of more than 7000 kcal...

Embodiment 2

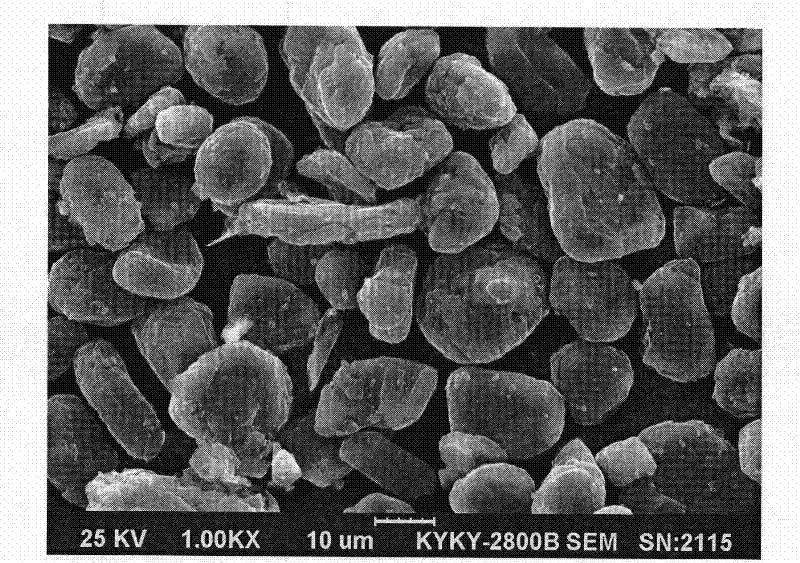

[0039] A negative electrode material for lithium ion batteries prepared from anthracite, its particle size distribution D10 is 6-10 μm, D50 is 17-20 μm, D90 is 35-50 μm, and its tap density is 1.1 g / cm 3 , the carbon content is 98.0%, and the degree of graphitization is 90%.

[0040] The preparation method of the lithium ion battery negative electrode material prepared with anthracite, it comprises the steps:

[0041](1) Select the anthracite whose Vdaf% is 0-7.5, Hdaf% is 0-4, the average maximum reflectance of vitrinite is higher than 6%, and the dry ash-free base high calorific value is lower than 22% MJ / KG. Crush and classify with a ball mill, the particle size distribution D50 is 0-30mm, and the tap density is 1.0g / cm 3 powdered anthracite precursor, and then with a density of 1.5g / cm 3 The mixture of magnetite powder and water is dense medium coal preparation, which washes out anthracite with a carbon content of more than 93%, a calorific value of more than 7000 kcal, ...

Embodiment 3

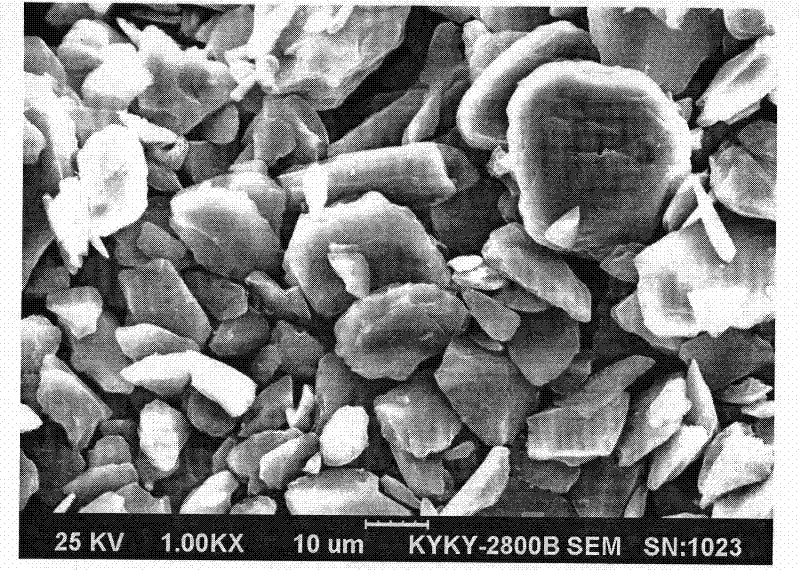

[0045] A lithium-ion battery negative electrode material prepared from anthracite, its particle size distribution D10 is 6-10 μm, D50 is 17-20 μm, D90 is 35-50 μm, and the tap density is 1.2 g / cm 3 , the carbon content is 98.5%, and the degree of graphitization is 92%.

[0046] The preparation method of the lithium ion battery negative electrode material prepared with anthracite, it comprises the steps:

[0047] (1) Select the anthracite whose Vdaf% is 0-7.5, Hdaf% is 0-4, the average maximum reflectance of vitrinite is higher than 6%, and the dry ash-free base high calorific value is lower than 22% MJ / KG. Crush and classify with a ball mill to obtain a particle size distribution D50 of 0-30mm and a tap density of 0.9g / cm 3 powdered anthracite precursor, and then use a density of 1 ~ 1.5g / cm 3 The mixture of magnetite powder and water is dense medium coal preparation, which washes out anthracite with a carbon content of more than 93%, a calorific value of more than 7000 kcal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com