Motor

A casing and component technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., to achieve high assembly efficiency, high connection structure strength, and improved heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

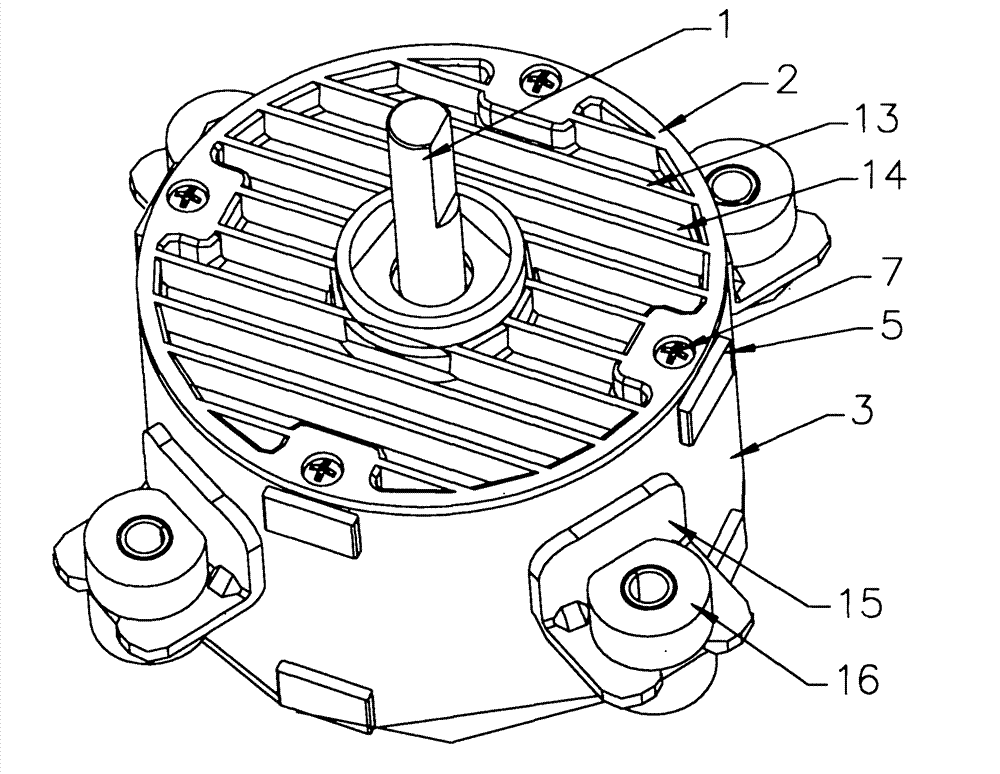

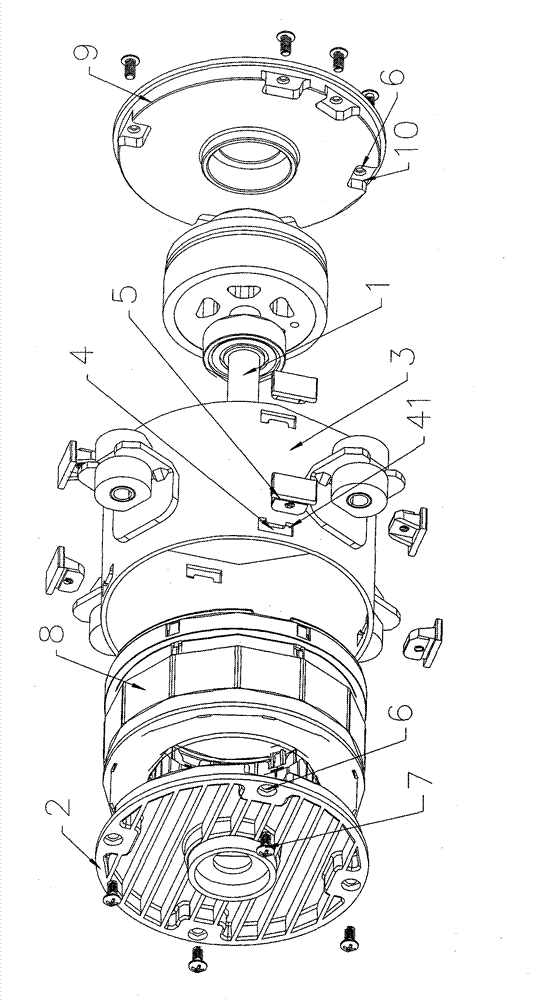

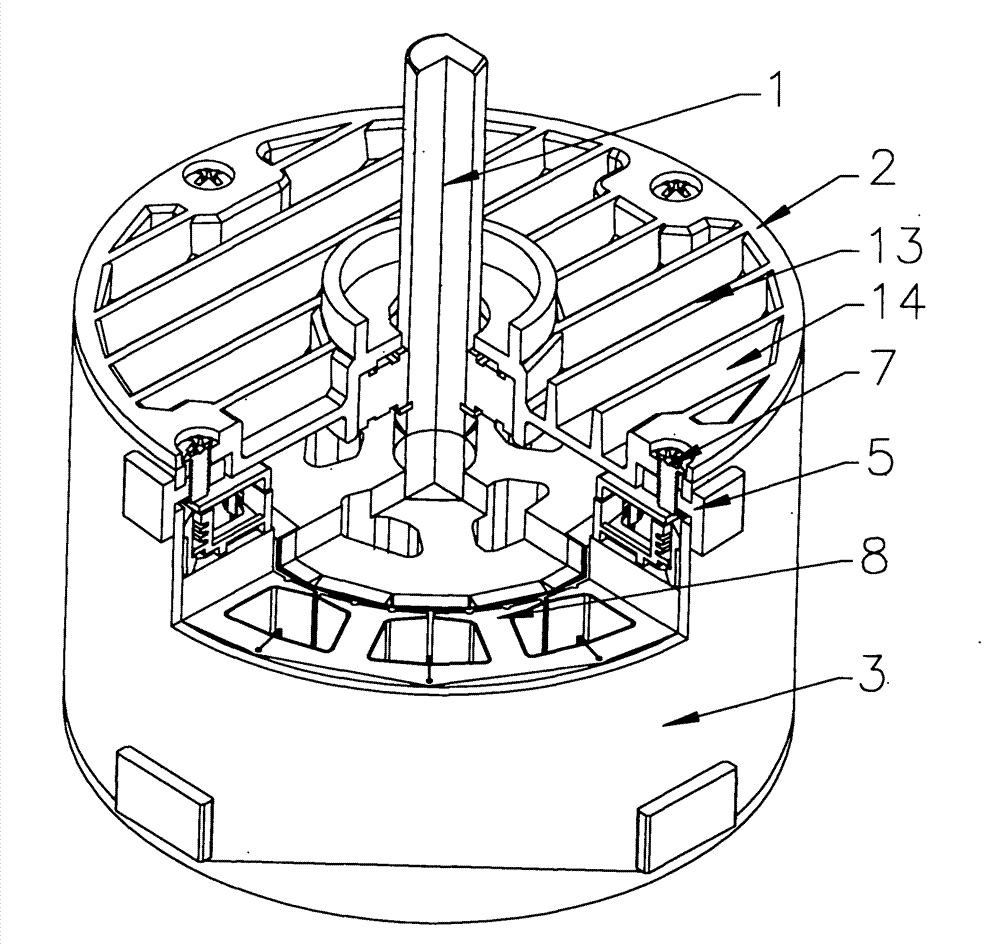

[0024] like Figure 1 to Figure 6 As shown, a motor includes a stator assembly, a rotor assembly, an end cover 2 and a casing 3, the stator assembly and the rotor assembly are installed in the casing 3, the end covers 2 are installed at both ends of the casing 3, and the motor shaft 1 Supported by bearings on the bearing chamber of the end cover 2, a number of sockets 4 are arranged along the circumference on the side wall surface of the casing 3 close to the end cover 2, and a plug-in 5 is installed on the socket 4, and the plug-in 5 includes The socket part 51 and the support part 52, the socket part 51 is buckled inside the socket 4, the support part 52 is close to the outer wall surface of the casing 3, the screw hole 53 is opened on the socket part 51, and the end cover 2 is opened. There is a mounting hole 6 correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com