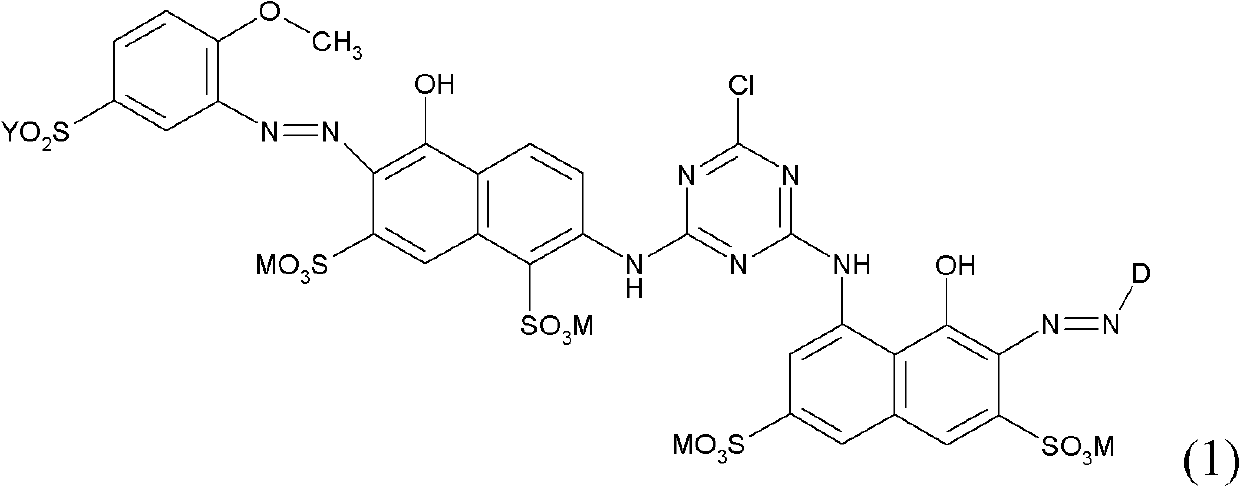

Fiber-reactive azo dyes, preparation thereof and use thereof

A technology of azo dyes and coupling, applied in the direction of reactive dyes, azo dyes, organic dyes, etc., can solve the problems that do not fully meet this demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

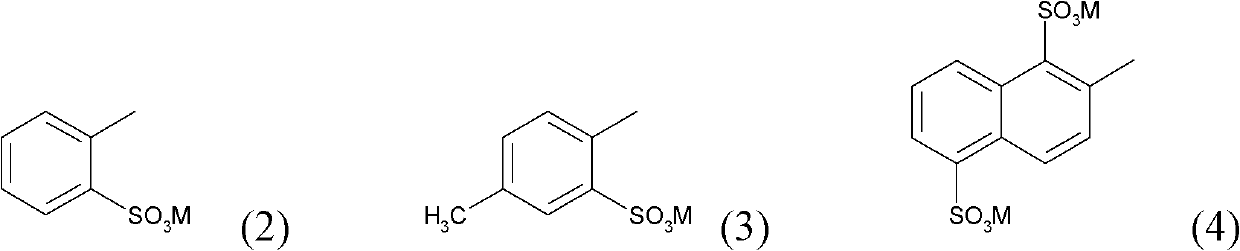

Method used

Image

Examples

example 1

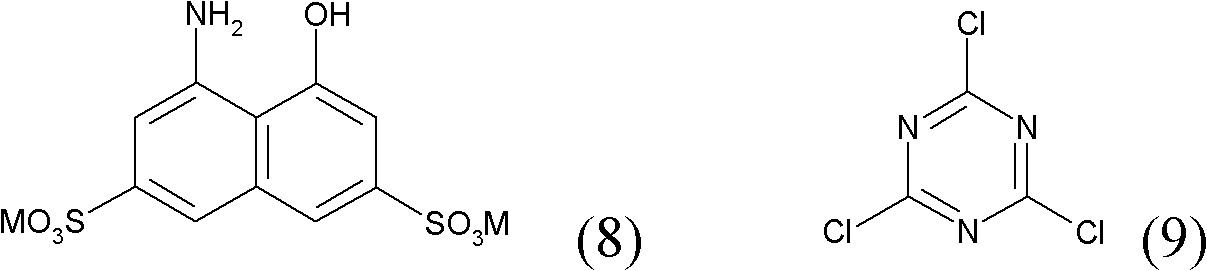

[0086] a) Suspend 19 parts of cyanuric chloride in 500 parts of water and 100 parts of ice. 32 parts of 2-amino-5-naphthol-1,7-disulfonic acid were added, followed by stirring at pH 1.5 at 0-5°C for about 3 hours.

[0087] b) 30 parts of 5-(β-sulfatoethanesulfonyl)-2-methoxyaniline are dissolved in 200 parts of water at pH 6-7. 7 parts of sodium nitrite were added, and the solution was added dropwise to a mixture of 20 parts of concentrated hydrochloric acid, 100 parts of ice and 50 parts of water. This was followed by stirring at 0-5°C for 2 hours. Decompose excess nitrite with sulfamic acid.

[0088] c) The diazo compound prepared according to b) is added dropwise to the reaction mixture obtained according to a) while maintaining the pH between 5 and 6 with 20% sodium carbonate solution. During this process the temperature was raised to room temperature.

[0089] d) Subsequently, 28 parts of 1-amino-8-naphthol-3,6-disulfonic acid are added at pH 3.5-4 and at a temperatur...

example 2

[0096] In a manner similar to that of Example 1, a dye (λ max = 518nm).

[0097]

example 3

[0099] In a manner similar to that of Example 1, a dye (λ max = 511 nm).

[0100]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com