Yellow dye, ink and electrowetting display

An electrowetting display and yellow dye technology, applied in ink, instrument, optics, etc., can solve the problems of low color development intensity and low polarity, and achieve the effect of ultra-high color development intensity, high saturation and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

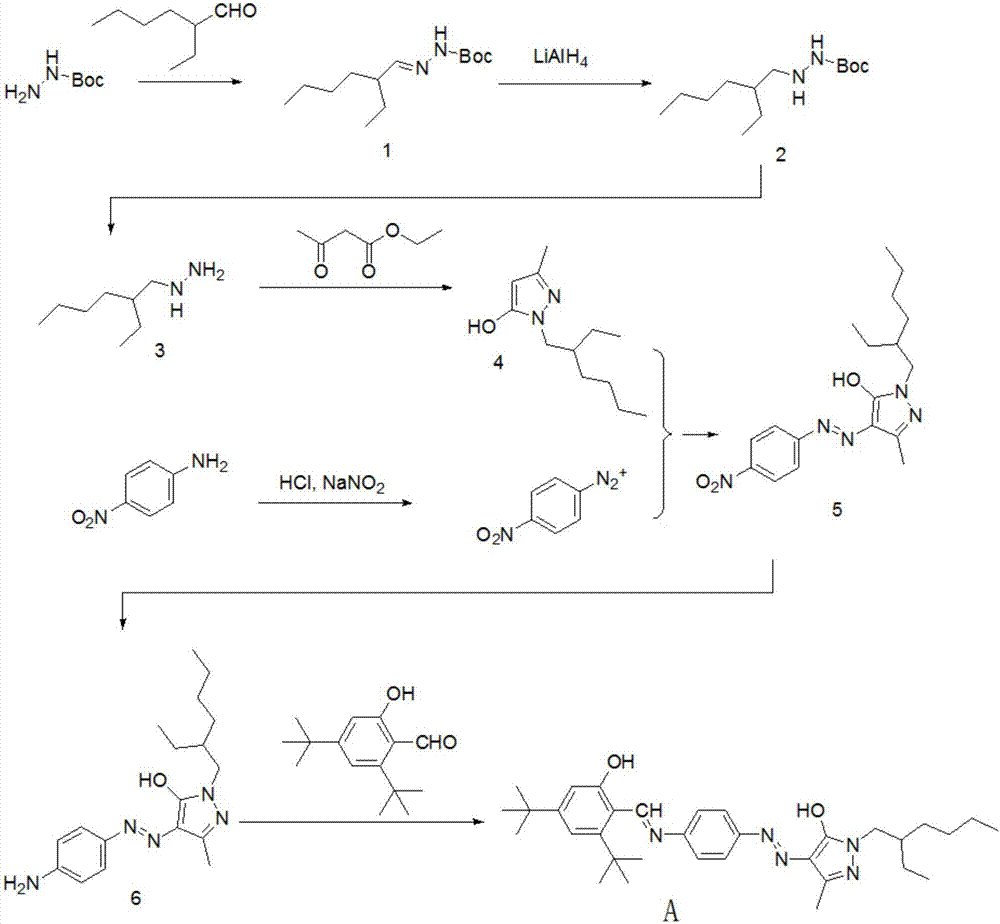

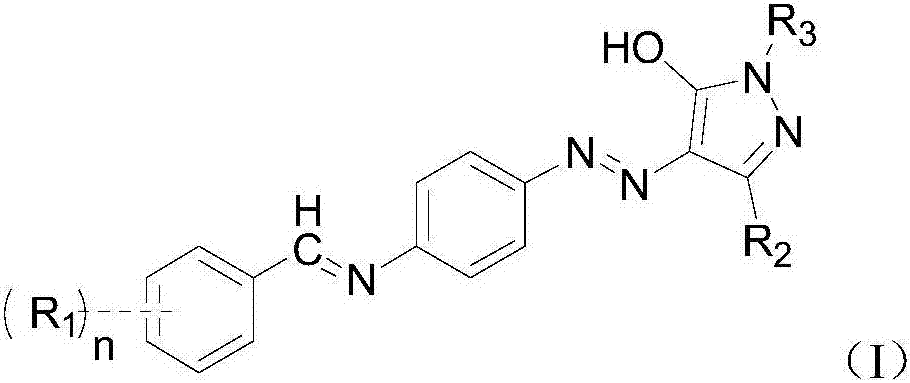

[0023] according to figure 1 The synthetic scheme shown is for the preparation of the dye:

[0024] Weigh 6.6g (132g / mol, 0.05mol) of tert-butoxycarbonylhydrazine and dissolve it in 50mL of n-hexane, weigh 6.7g (114g / mol, 0.058mol) of isooctylaldehyde and slowly add it dropwise to the above solution, heat up to reflux reaction 2h. After the reaction was completed, the solvent was evaporated to dryness to obtain compound 1 with a yield of 100%.

[0025] Cool compound 1 to 0-5°C, weigh 100 mL of 1 mol / L borane tetrahydrofuran solution and slowly add it dropwise to the above reaction device, the developer is dichloromethane / petroleum ether = 1:1, and react for 2 hours to obtain compound 2. Measure 15mL of concentrated hydrochloric acid, slowly add it dropwise to the above solution, heat to reflux after no obvious bubbles, and react for 0.5h. After the reaction was completed, it was cooled, and the precipitated boric acid was removed by suction filtration, and the solution was ...

Embodiment 2

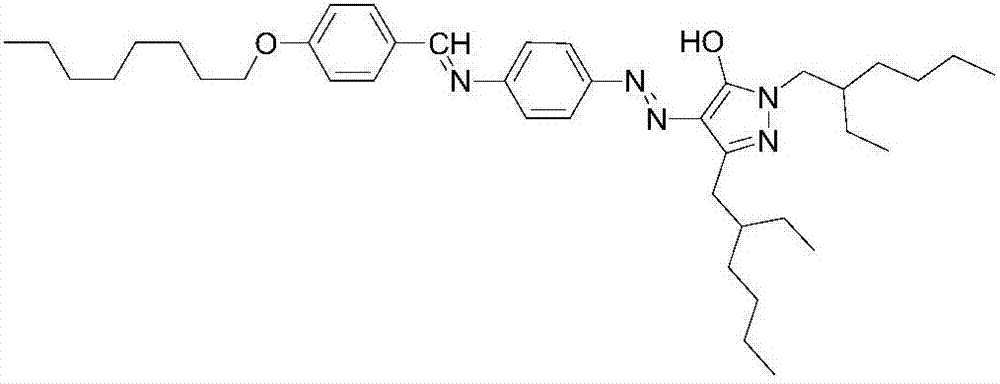

[0032] Adopt synthetic method same synthetic method as embodiment 1 compound B, its structural formula is:

[0033]

[0034] Using nuclear magnetic spectrum analysis, its hydrogen nuclear magnetic spectrum data are: 1 H NMR (CDCl 3 ): 11.763(s,1H), 7.536-7.51(d,2H), 7.313-7.304(d,4H), 6.884(s,2H), 3.941(t,2H), 3.687(d,3H), 2.505( t,3H), 1.851-1.258(m,30H), 0.967(m,15H). Spectral data demonstrated the correct structure.

[0035] The yellow dye prepared in this example has good light stability and high solubility, and can be dissolved in an organic solvent to prepare an ink. Especially in non-polar organic solvents, such as n-decane, n-dodecane, n-tetradecane, n-hexadecane, fluorine-containing alkanes, silane, etc., the dye has a very high solubility, and the dye can be dissolved In a non-polar organic solvent, the ink prepared is bright in color, high in saturation, and super high in color development strength, which is very suitable for electrowetting display.

Embodiment 3

[0037] Weigh 0.1 g of the dyes prepared in Example 1-2, dissolve them in 10 mL of n-dodecane, and prepare electrowetting display inks I and II respectively. The color, maximum absorption wavelength (λmax), solubility C at 25° C., molar absorptivity ε and ε·C of the prepared ink material are shown in Table 1.

[0038] Table 1 Ink material performance results

[0039] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com