Solid formaldehyde-free pigment preparations

A pigment preparation, formaldehyde technology, used in adhesives, organic dyes, fibrous fillers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

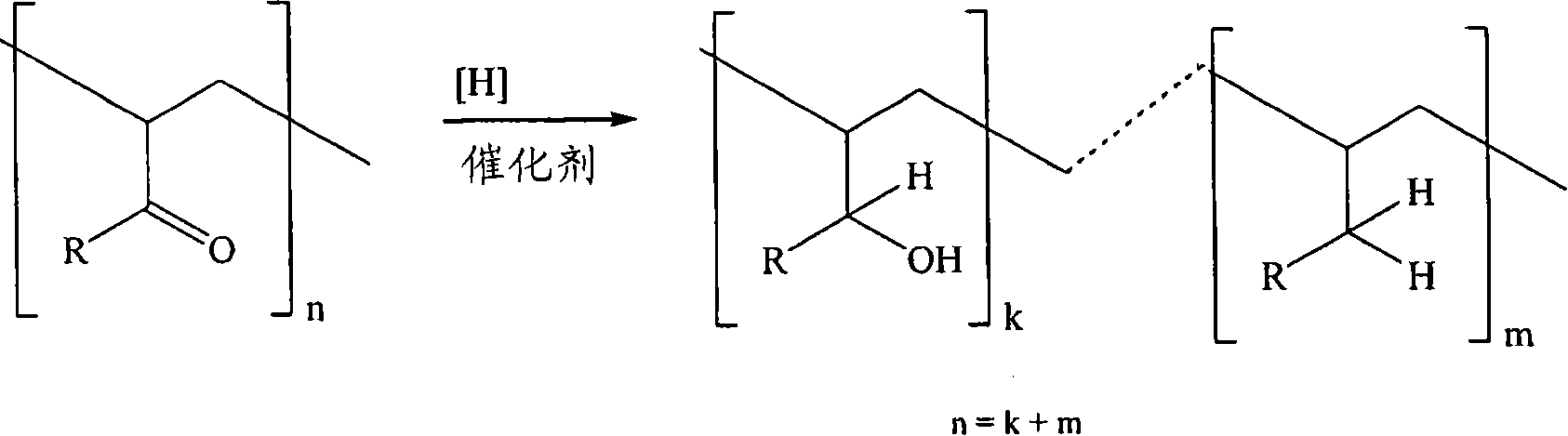

[0068] 1) Preparation of carbonyl hydrogenated ketone / aldehyde resins (not of the invention)

[0069] 1200g of acetophenone, 220g of methanol, 0.3g of benzyltributylammonium chloride and 360g of 30% formaldehyde aqueous solution were preset and stirred evenly. Then 32 g of 25% aqueous caustic soda were added with stirring. Then 655 g of a 30% aqueous formaldehyde solution were added with stirring at 80 to 85° C. over 90 min. After stirring for 5 h at reflux temperature the stirrer was switched off and the aqueous phase was separated from the resin phase. The crude product was washed with aqueous acetic acid until a molten sample of the resin was clear. The resin is then dried by distillation.

[0070] 1270 g of a slightly yellowish resin were obtained. The resin is clear and brittle and has a melting point of 72°C. It is soluble in, for example, acetates such as butyl acetate and ethyl acetate, soluble in aromatics such as toluene and xylene, and insoluble in ethanol.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com