Scroll fluid machine

A fluid machinery and scroll technology, applied in the direction of rotary piston machinery, mechanical equipment, rotary piston pumps, etc., can solve the problems of rising manufacturing costs, pressure pulsation, and reduced reliability, and achieve manufacturing cost reduction and volumetric efficiency The effect of improving and reducing the amount of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

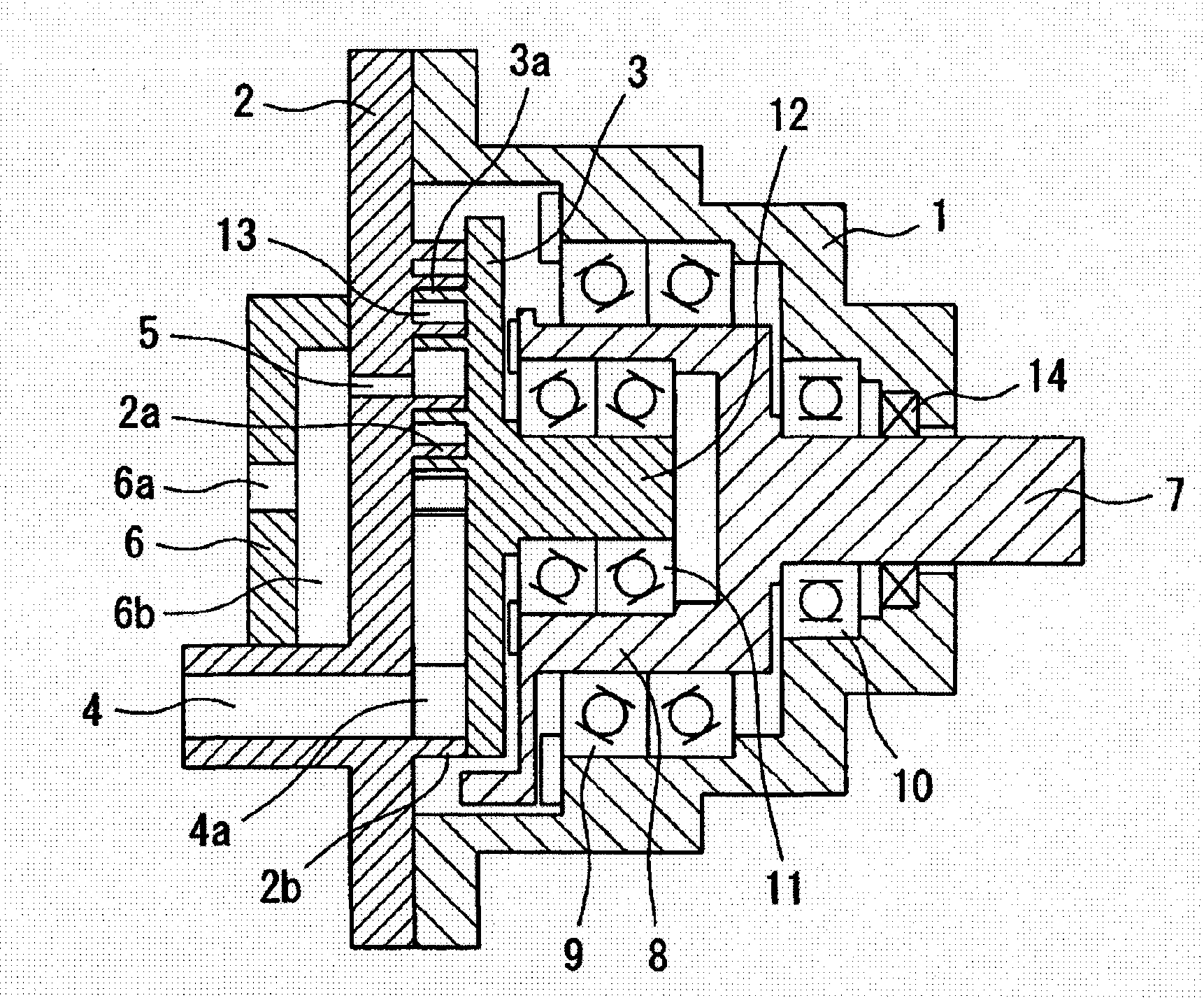

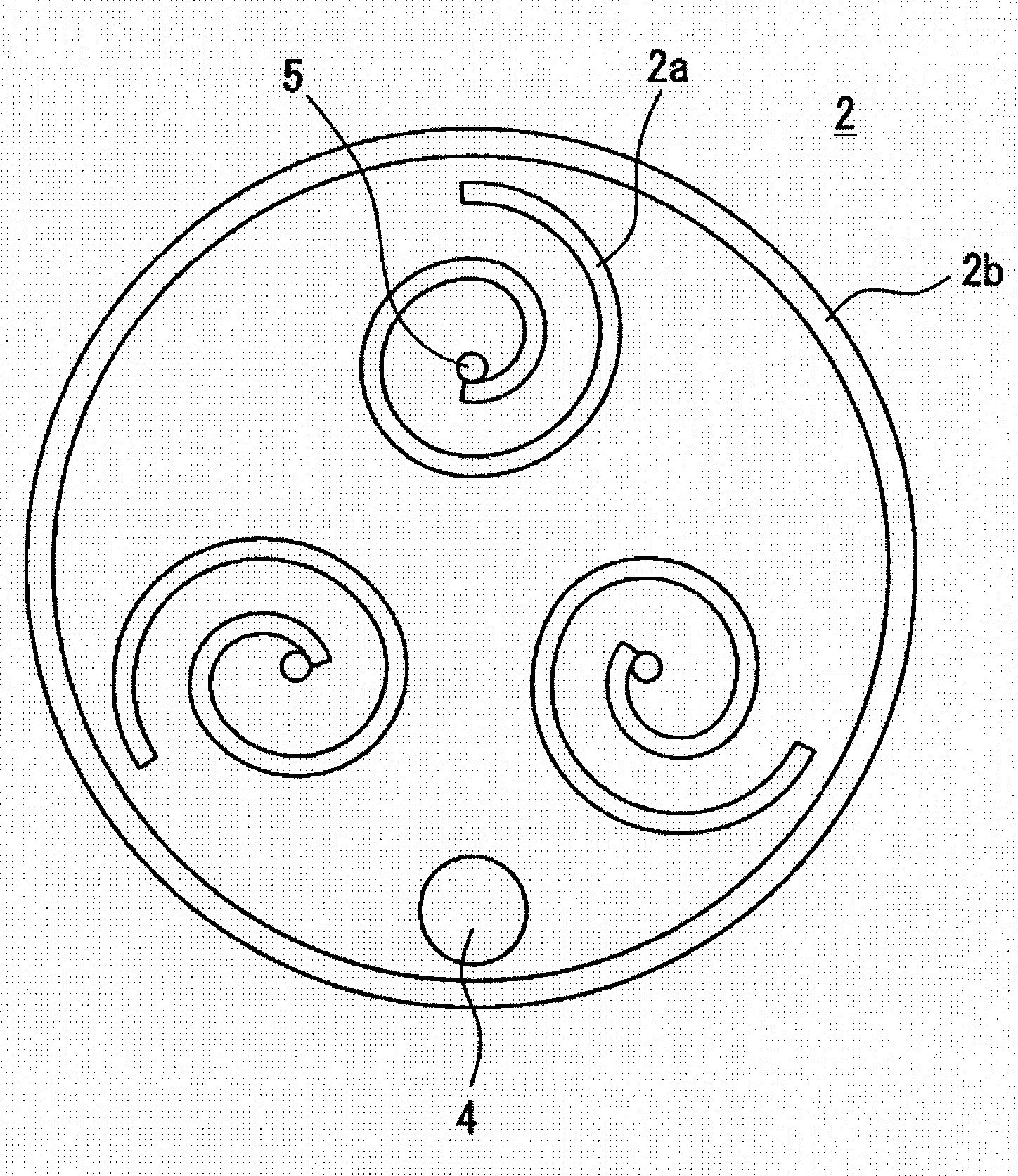

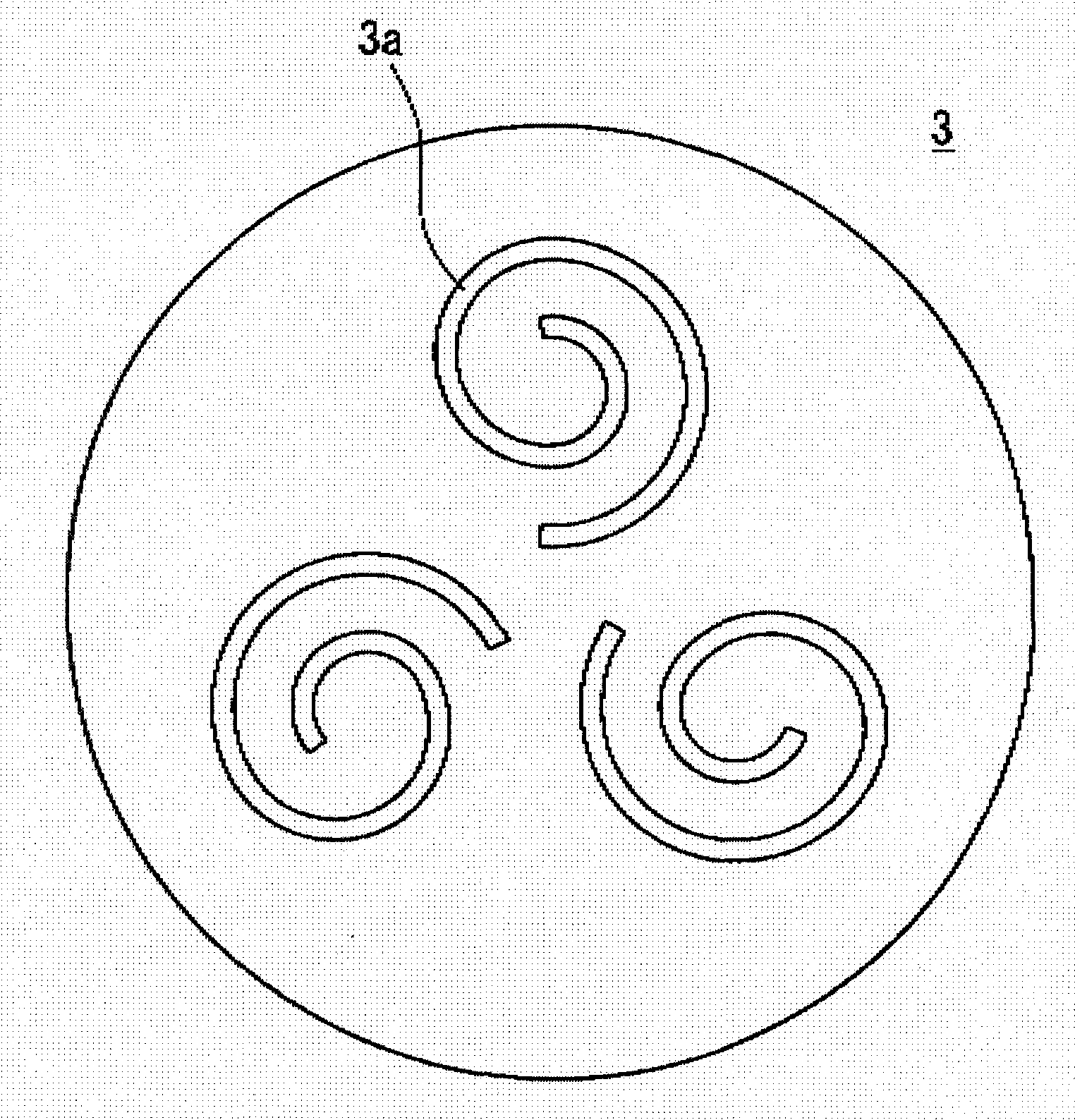

[0055] figure 1 It is a figure which shows the scroll type fluid machine of this invention; figure 2 yes means figure 1 A diagram of the fixed scroll of the scroll fluid machine shown; image 3 yes means figure 1 A diagram of the orbiting scroll of the scroll fluid machine shown. Such as figure 1 As shown, a fixed scroll 2 is installed on the casing 1, and three fixed flanges 2a are installed on the fixed scroll 2. The angular interval between adjacent fixed flanges 2a is 120 degrees, and the mutual phases are staggered by 120 degrees. A sealing wall 2b is provided on the outer periphery of the fixed scroll 2, a suction port 4 is provided on the fixed scroll 2, and a discharge port 5 is provided on the center of the fixed flange 2a of the fixed scroll 2. In addition, the rotating shaft 7 and the eccentric bushing 8 are integrally formed, the rotating shaft 7 and the eccentric bushing 8 are rotatably supported on the housing 1 via the main bearing 9 and the sub bearing 10...

no. 2 approach

[0062] Figure 5 It is a figure which shows another scroll type fluid machine of this invention. As shown in the figure, the cover 6 is fixed on the casing 1, and the fixed scroll 2 is installed on the cover 6 in a manner that can move upward along the axial direction of the rotary shaft 12, between the cover 6 and the fixed scroll 2 A discharge chamber gasket 6c is provided, and the fixed scroll 2 is prevented from rotating relative to the cover 6 by a pin 15 .

[0063] This scroll fluid machine and figure 1 Similarly, the scroll fluid machine shown does not need to provide an anti-rotation mechanism to prevent the rotary shaft 12 and the orbiting scroll 3 from rotating, so the structure becomes simple, the manufacturing cost is reduced, and the reliability is improved. And, since the fixed scroll 2 is pressed to the Figure 5 On the right side of the paper, the front end of the fixed flange 2a is in close contact with the orbiting scroll 3, and the front end of the orbiti...

no. 3 approach

[0065] Image 6 It is a figure which shows another scroll type fluid machine of this invention. As shown in the figure, the stator 20 is fixed on the casing 1, and the rotating shaft 24 is rotatably supported on the casing 1 via the first and second rotating bearings 22a, 22b. The rotor 21 is mounted on the rotating shaft 24, and the machine The housing 1, the stator 20, the rotating shaft 24, the rotor 21, and the like constitute the structure of the motor. In addition, the rotary shaft 25 (rotary member) is rotatably supported in the eccentric hole of the rotary shaft 24 via the first and second eccentric bearings 23a, 23b, and the center line of the rotary shaft 24 and the center line of the rotary shaft 25 deviate. That is, the rotary shaft 25 and the rotary shaft 24 are eccentrically and rotatably supported. Then, the orbiting flanges of the orbiting scroll 3 are attached to the rotary shaft 25 by bolts or the like in a state where relative rotation is prevented at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com