Automobile electronic knob gear shift and implementation method thereof

A technology of automotive electronics and implementation methods, applied in vehicle components, circuits or fluid pipelines, control devices, etc., can solve the problems of easy mechanical wear and laborious operation, and achieve the advantages of avoiding mechanical friction, stable and reliable operation, and expanding the use space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

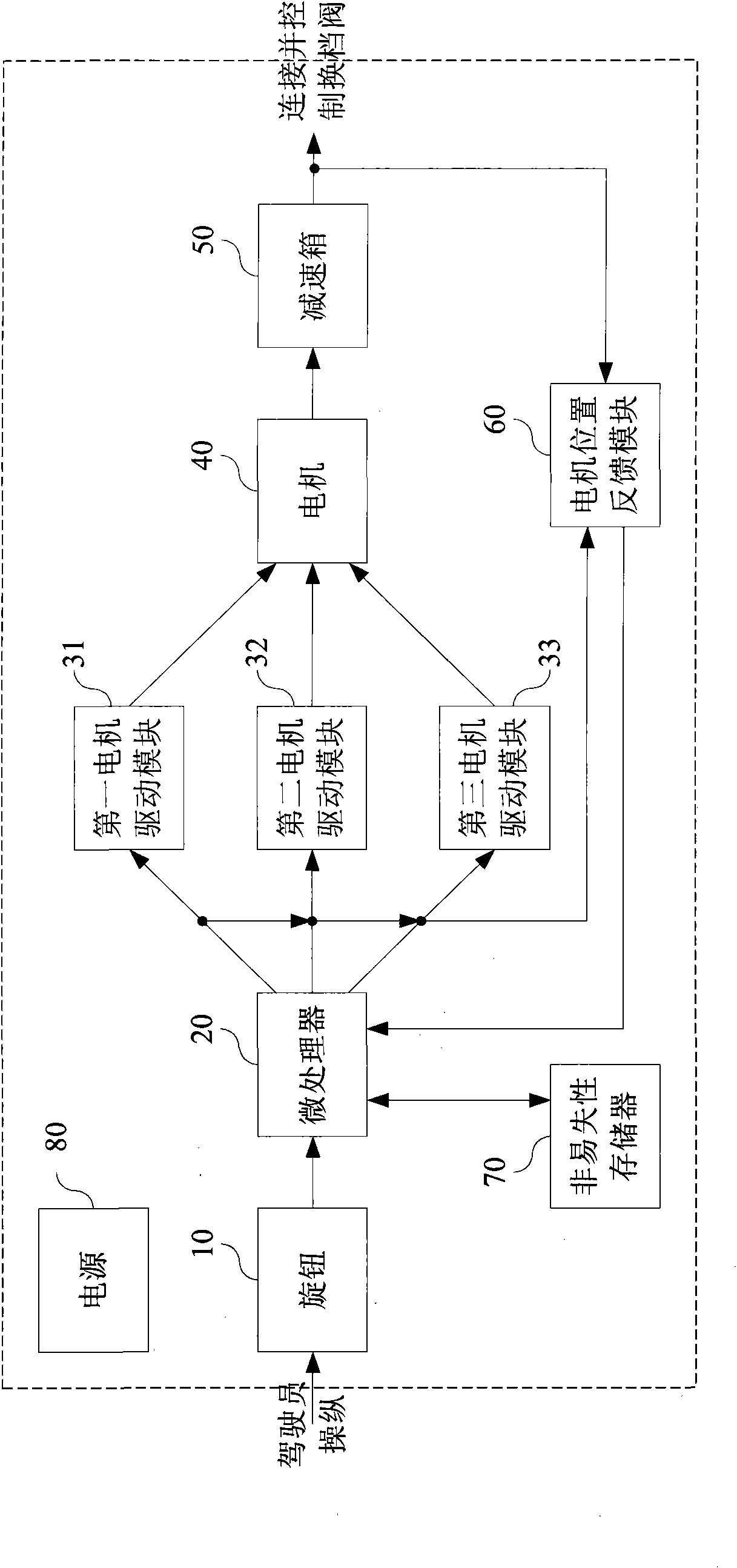

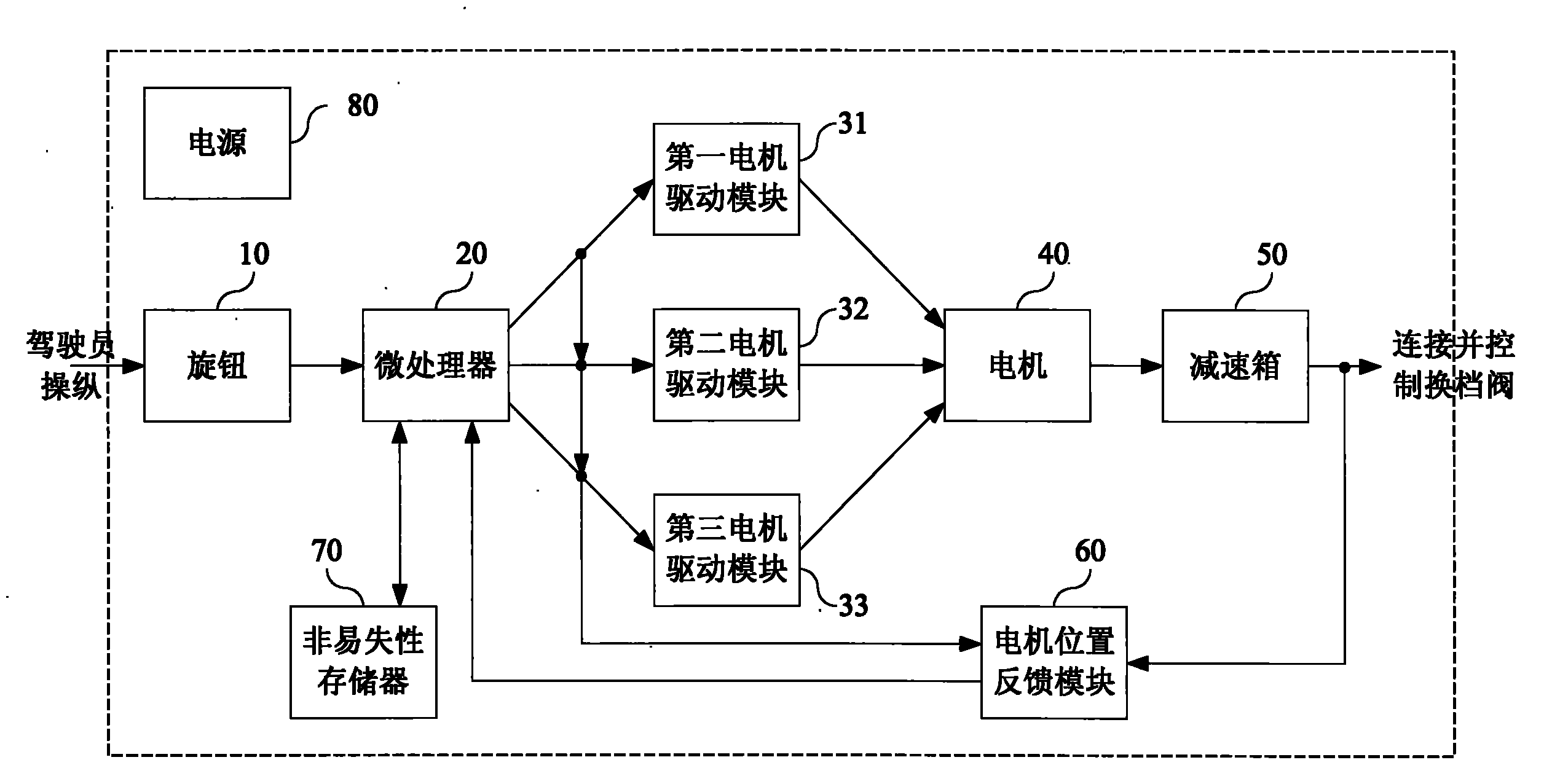

[0022] see figure 1 , the automotive electronic knob shifter of the present invention comprises:

[0023] - Knob 10, at least having a rotary function. Different rotation positions of the knob 10 represent different gears of the vehicle, and these gears at least include P gear, R gear, N gear and D gear, and some vehicles also have S gear, L gear, etc. The knob 10 is used to represent all gears of the vehicle. stalls.

[0024] -The microprocessor 20 detects the position of the knob 10 and sends a pulse signal to drive the motor 40 to rotate to one of the first motor drive module 31, or the second motor drive module 32, or the third motor drive module 33; the microprocessor The microprocessor 20 also receives the feedback pulse signal and the feedback rotation signal from the motor position feedback module 60 ; the microprocessor 20 stores the sent and / or received data in the non-volatile memory 70 .

[0025] - The first motor drive module 31 receives the pulse signal sent b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com