Novel electric vehicle body

A technology for electric vehicles and car bodies, which is applied to the connection between vehicle components, superstructure sub-assemblies, and superstructures, etc. It can solve the problems of incomplete protection of members, imperfect price and supporting facilities, and road system efficiency. Reduce and other problems, to achieve the effect of solving production consistency, improving user-friendly performance, and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

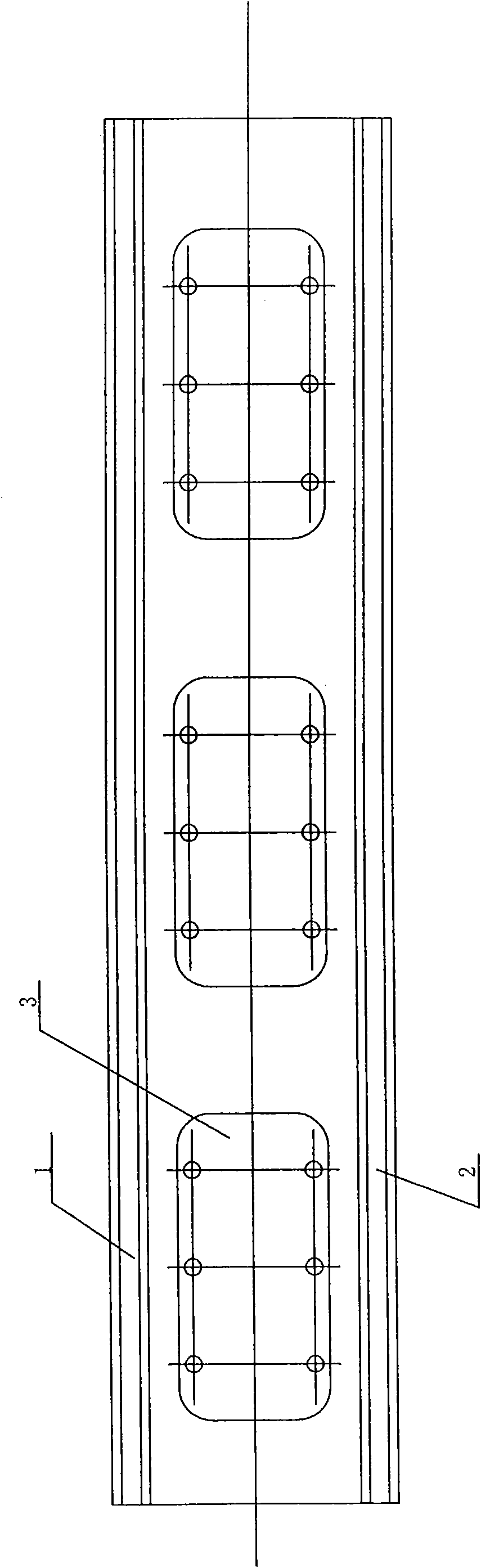

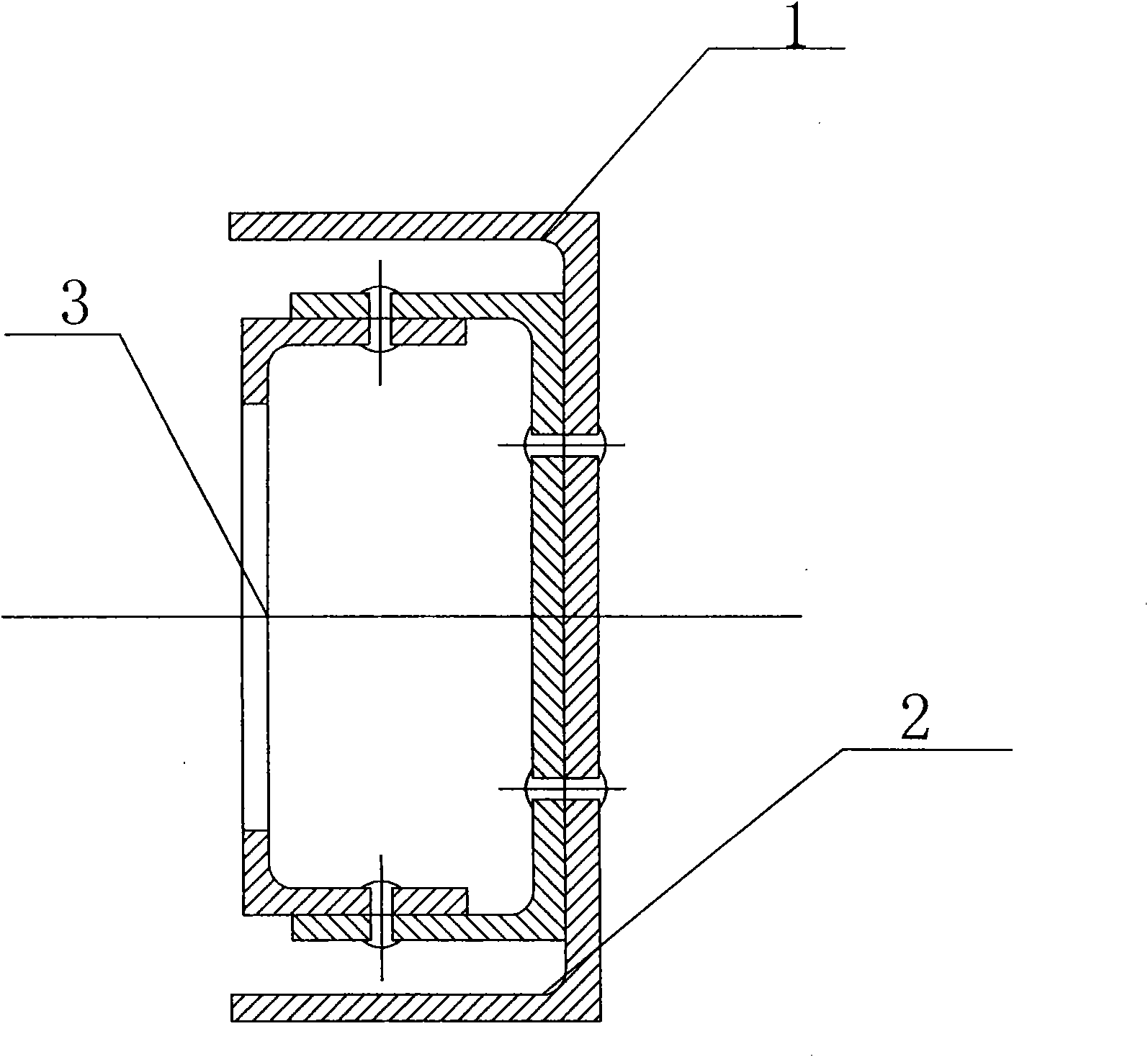

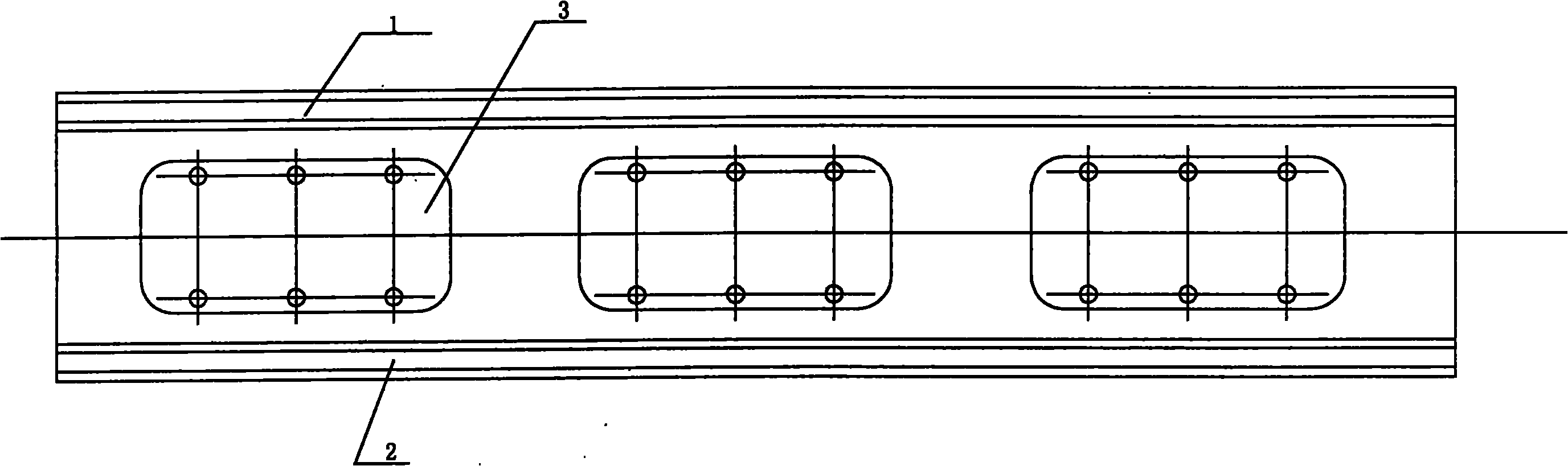

[0009] exist figure 1 and figure 2 Among them, the present invention is a new type of electric vehicle body, the upper part of the vehicle body is set as an upper body module 1, the upper body module 1 is made of aluminum alloy, the upper body module is formed by extrusion or die-casting, and the lower part of the body is set as The lower body module 2, the lower body module 2 is made of steel plate or aluminum alloy, the upper body module is stamped or die-cast, the upper body module 1 and the lower body module 2 are connected to form an integral body, the upper body module 1 and the lower body module 2 are threaded or riveted, and a chassis system is provided at the bottom of the body. The body and chassis system are threaded, welded or riveted. , stamping, machining or die-casting, the body is provided with a body opening and closing module 3, the body opening and closing module 3 is a steel plate and an aluminum alloy plate, the body opening and closing module is stampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com