Surface compound strengthening process for aluminum alloy material

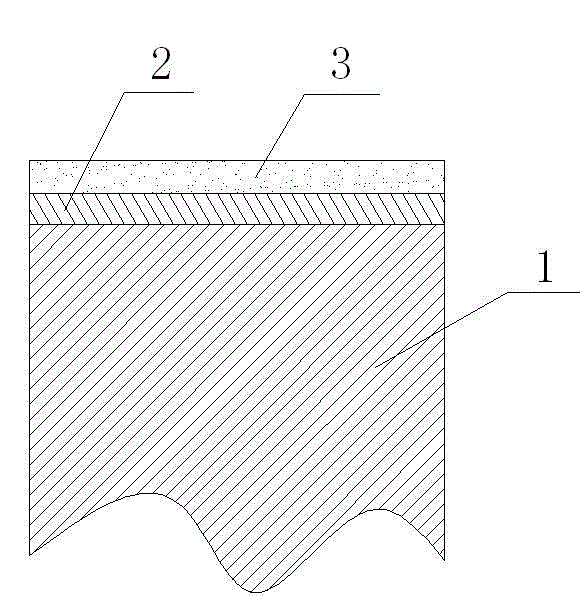

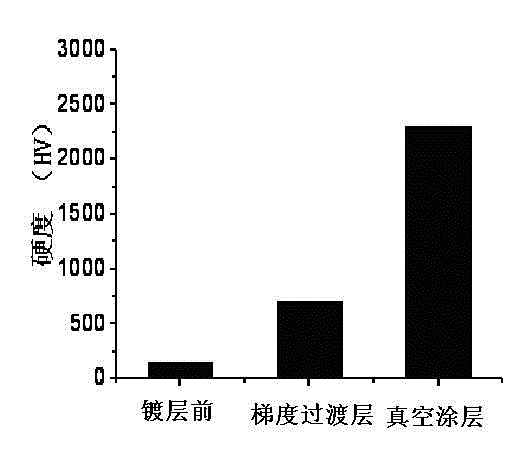

An aluminum alloy material and surface compounding technology, which is applied in metal material coating process, superimposed layer plating, coating, etc., can solve the problems of poor wear resistance, low hardness, poor bonding strength, etc., and achieve wear resistance Good, high bonding strength, high hardness and wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the first step, the plating thickness of aluminum and aluminum alloy surface is 2μm Ni plating:

[0024] Electroplating Ni layer process: mechanical polishing → gasoline or carbon tetrachloride degreasing → mounting → chemical degreasing (alkali etching process) → descaling or light emission in a 1:1 nitric acid and 5% hydrofluoric acid solution ( Acid etching process) → water washing → activation → water washing → nickel plating → water washing → blow-drying.

[0025] (1) Alkaline etching process: Na 2 CO 3 30g / L, Na 3 PO 4 30g / L, additive 2~4 g / L, OP-10 emulsifier 0.5~1 mL / L, temperature 75~85℃, time 30~60s;

[0026] (2) Acid etching process: HNO 3 3 parts, 1 part HF, a small amount of water, temperature room temperature, time 20-40s;

[0027] (3) Nickel electroplating solution formula and process parameters (the name should correspond to the above process flow, the terminology should be consistent): nickel sulfate (NiSO 4 ·7H 2 O) 250g / L, nickel chloride (NiCl 2 ·6H 2 O...

Embodiment 2

[0032] The first step: the electroless plating thickness of aluminum and aluminum alloy surface is 10μm Ni coating.

[0033] In the second step, the aluminum alloy mold after the Ni plating treatment is cleaned by an ultrasonic cleaning line to remove the electroless plating residue, and then placed in a constant temperature drying oven at a constant temperature of 75°C for 2 hours.

[0034] The third step: Hollow cathode ion plating deposition of CrN coating process and parameters:

[0035] Fix the dried aluminum alloy mold on the support, put it into the hollow cathode coating machine, put Cr plating material in the crucible of the coating machine, adjust the rotation speed of the workpiece support to 6-10 rpm, and pump to the background vacuum 2.5-3.0×10- 3 Pa, turn on the heater at the same time and raise the temperature to 200-300℃; turn on the Ar gas flow valve, adjust the vacuum chamber to about 0.5-1 Pa, apply a negative bias voltage of 300-800 V to the substrate, and perform...

Embodiment 3

[0037] The first step: the electroless plating thickness of aluminum and aluminum alloy surface is 4μm Ni-P coating.

[0038] In the second step, the aluminum alloy mold after the Ni-P plating treatment is cleaned by an ultrasonic cleaning line to remove the electroless plating residue, and then placed in a constant temperature drying oven at a constant temperature of 80°C for 1.5 hours.

[0039] The third step: magnetron sputtering ion plating deposition of two TiN coatings, the deposition temperature is 200 ℃, the thickness of the two TiN coatings is 4 μm.

[0040] The technical solutions of electroplating and electroless plating of the present invention are all well-known technologies, and therefore will not be described in detail. Multi-arc ion plating, hollow cathode ion plating, and magnetron sputtering ion plating also use the existing low deposition temperature (180-250°C) vacuum coating technology, and other technical solutions of the present invention can be implemented.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com