Self-propelled wheel

A self-propelled wheel and tire technology, applied in hydropower, engine components, machines/engines, etc., can solve the problems of low liquid utilization, uncompact structure, and low space utilization, so as to save resources, protect the environment, and reduce heat. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

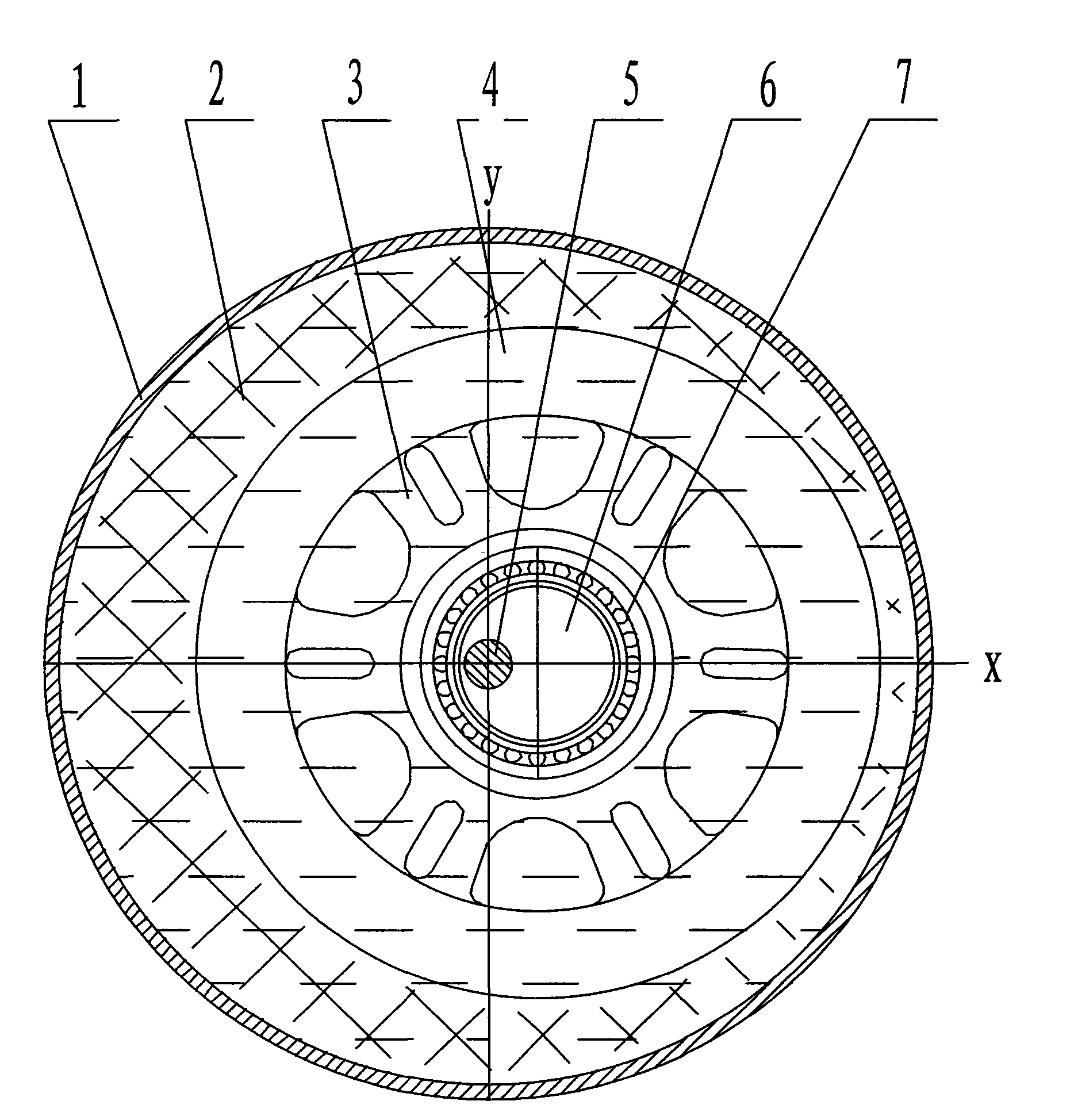

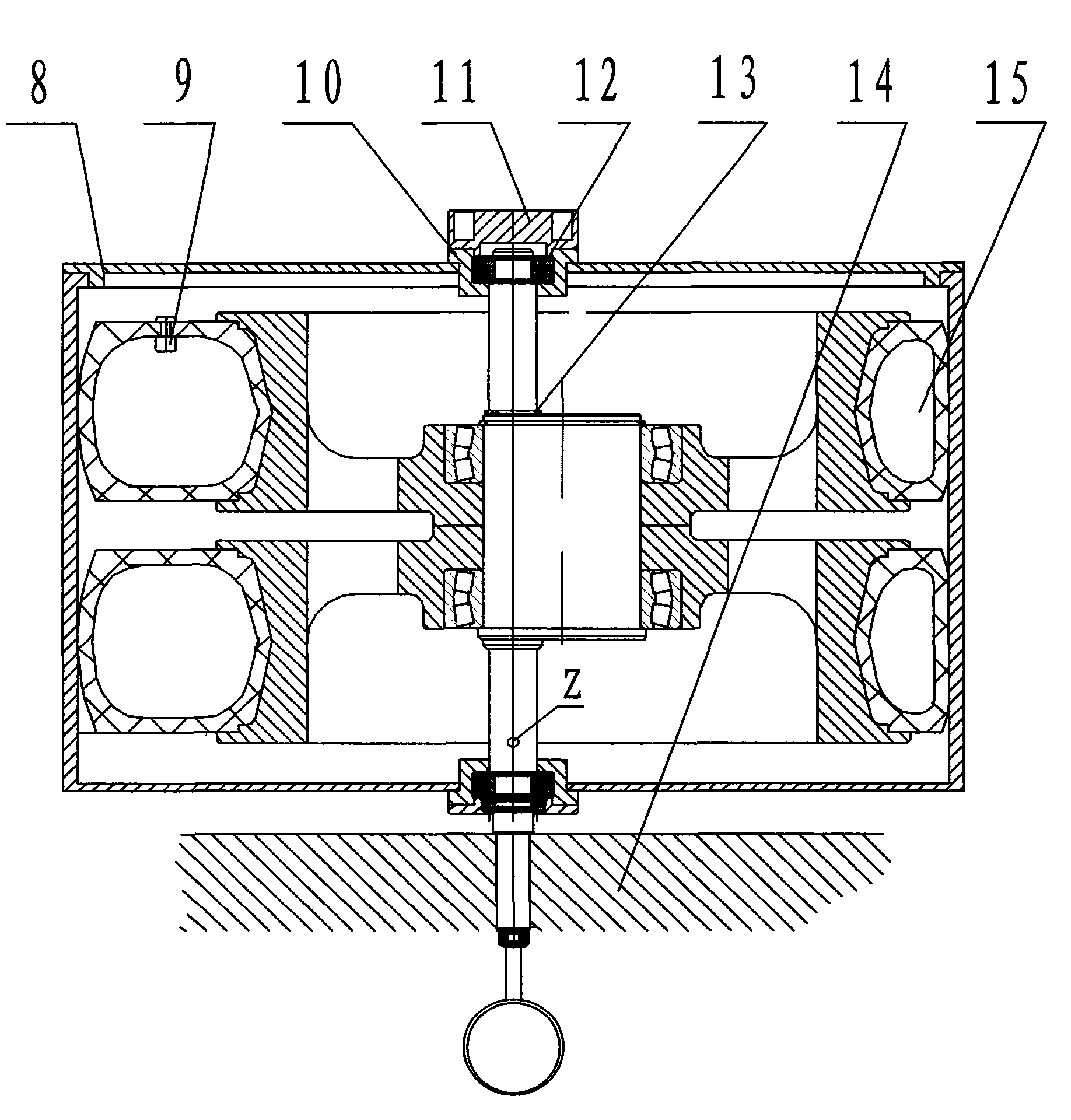

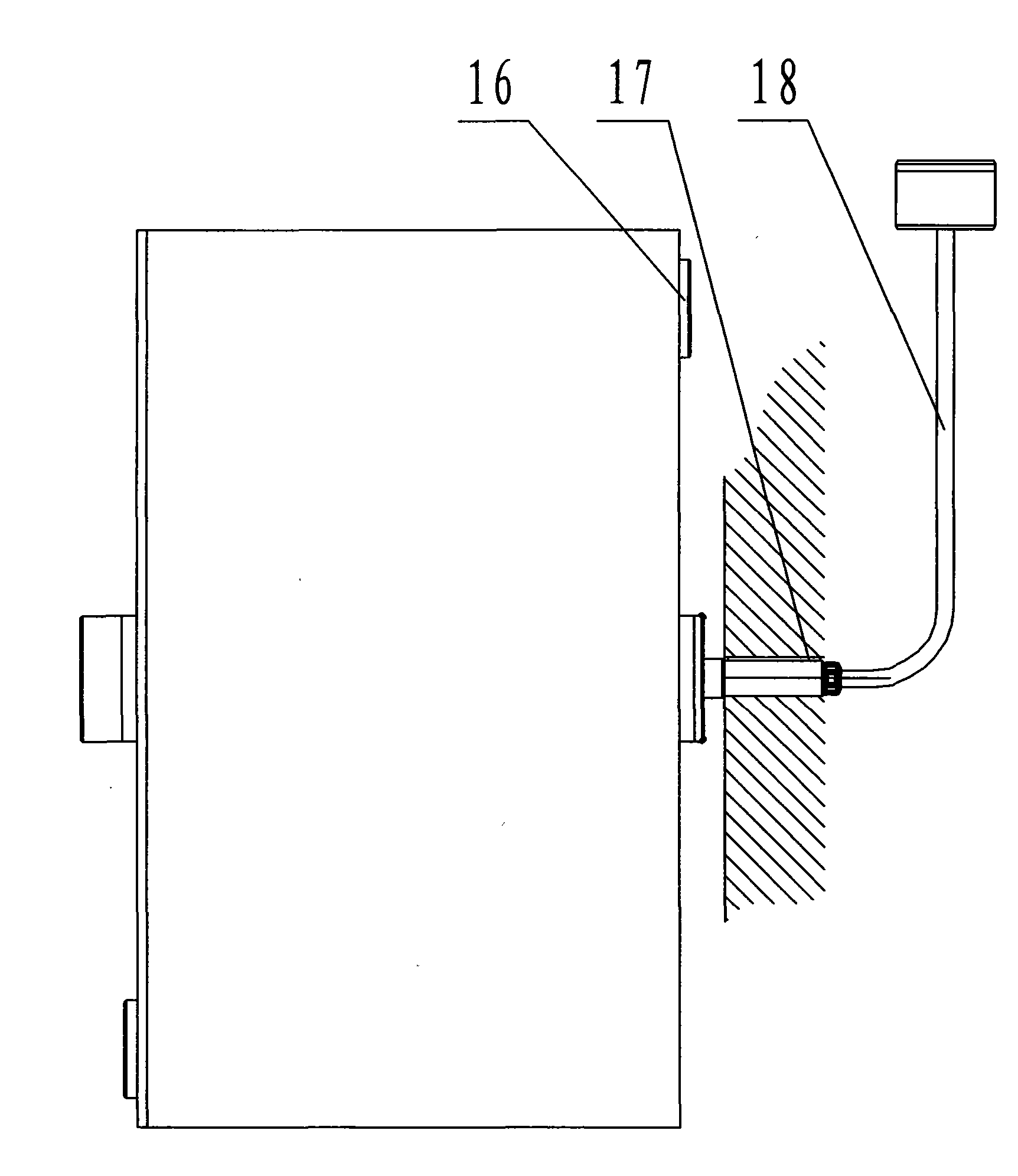

[0010] In the figure, 1. Wheel shell, 2. Tire, 3. Hub, 4. Liquid, 5. Fixed shaft, 6. Eccentric shaft, 7. Bearing, 8. Wheel shell cover, 9. Air valve, 10. Bearing seat, 11. Counter wheel, 12. Bearing, 13. Circlip, 14. Fixing frame, 15. Gas, 16. Cover, 17. Key, 18. Filling pipe.

[0011] The structure of the bicycle wheel is as attached figure 1 to attach image 3 As shown, on the fixed frame (14), a stationary fixed shaft (5) is equipped with a key (17) and a keyway. The shaft head is processed with a liquid hole communicating with the hole Z, so that the liquid (4) can be added to the wheel housing (1) through the liquid filling pipe (18), and assembled through the bearings (12) on both sides of the fixed shaft (5) In the airtight wheel housing composed of the wheel housing (1), the wheel housing cover (8) and the bearing seat (10), the eccentric shaft (6) passes through the boss of the fixed shaft (5), the key and the circlip (13 ) is positioned in the middle of the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com