Mechanical button sewing machine

A stitching machine, mechanical technology, applied in mechanical equipment, belt fasteners, belts/chains/gears, etc., can solve problems such as large operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

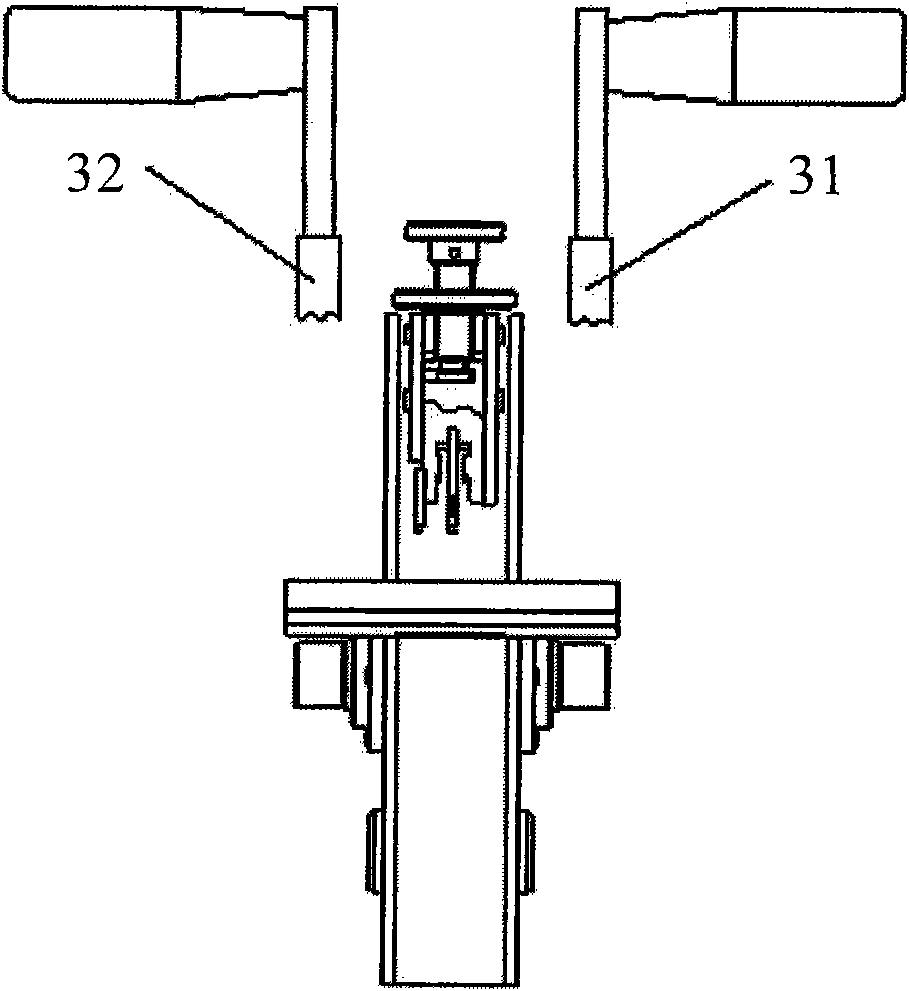

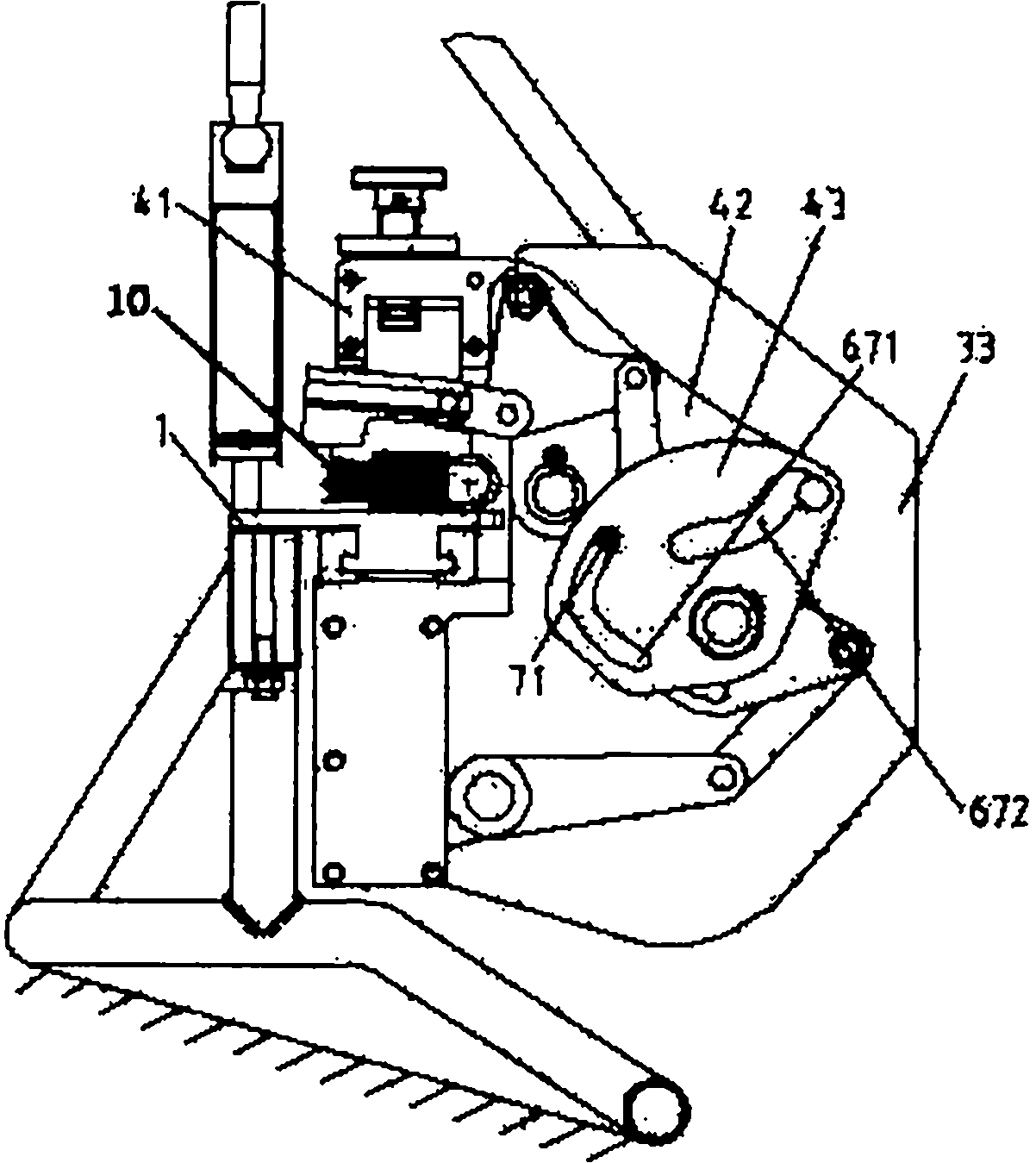

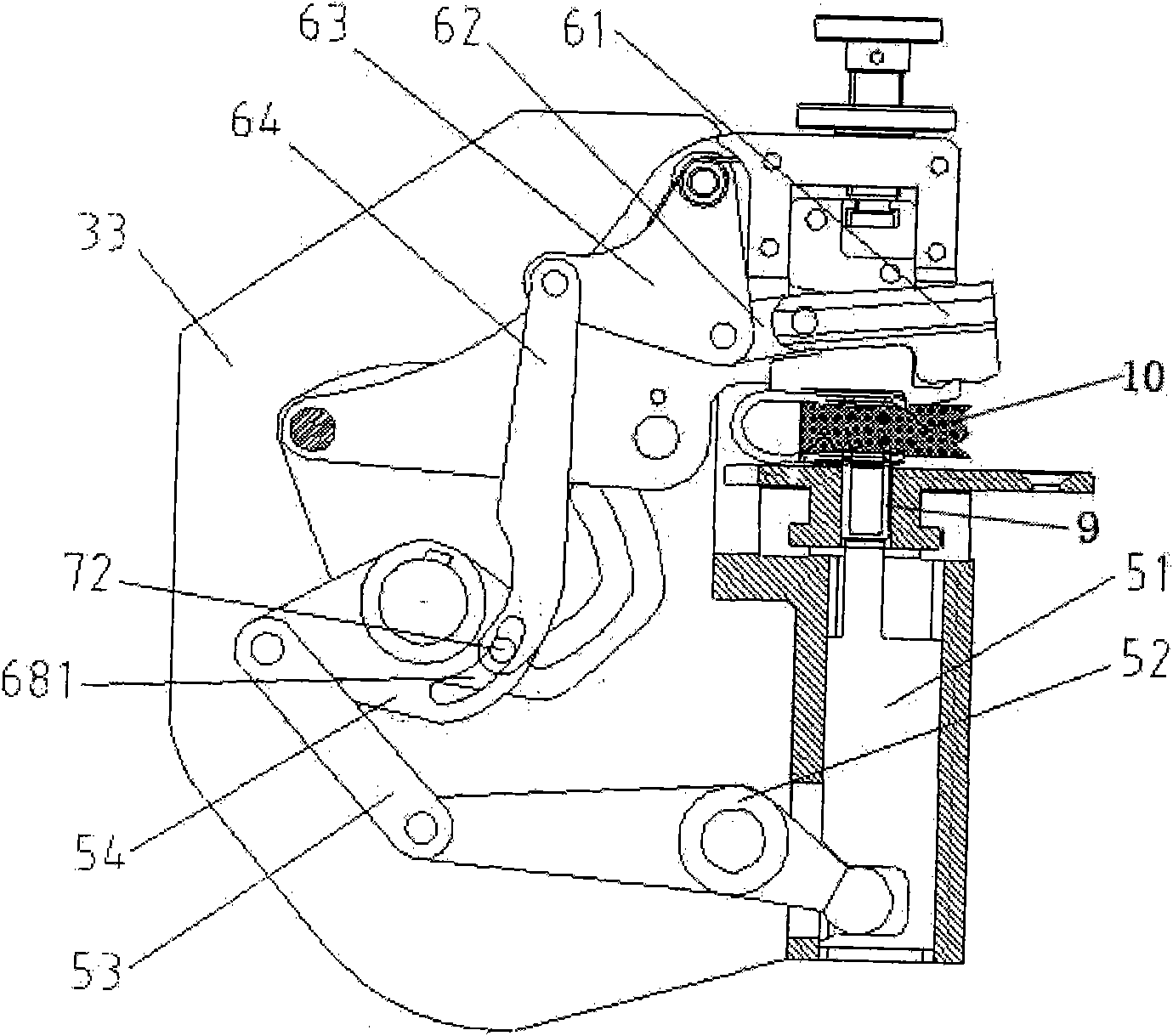

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention provides a mechanical button binding machine, comprising a gusset plate 1, a machine head and a handle that can move along the gusset plate 1, and the machine head includes a buckle pressing mechanism and a nail threading mechanism , the machine head is also provided with a nail bending mechanism, the buckle pressing mechanism includes a pressure head 41, a pressure head support plate 42 and a left turning block 43, and the nail piercing mechanism includes a nail hammer 51, a nail pendulum Rod 52, nail-piercing connecting rod 53 and right turning block 54, described nail-bending mechanism includes nail-pull plate 61, nail-pull connecting rod 62, triangular turning block 63 and nail-bending push rod 64, and described handle includes left handle 31 and the right handle 32, the left handle 31 is eccentrically fixedly connected to the left turning block 43, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com