Automobile wiring harness production management system

A production management system and automotive wiring harness technology, applied in the field of automotive wiring harness production systems, can solve problems such as high training costs, difficult processing techniques, and different production techniques, and achieve the effects of reducing misoperation, reducing waste products, and reducing deductions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

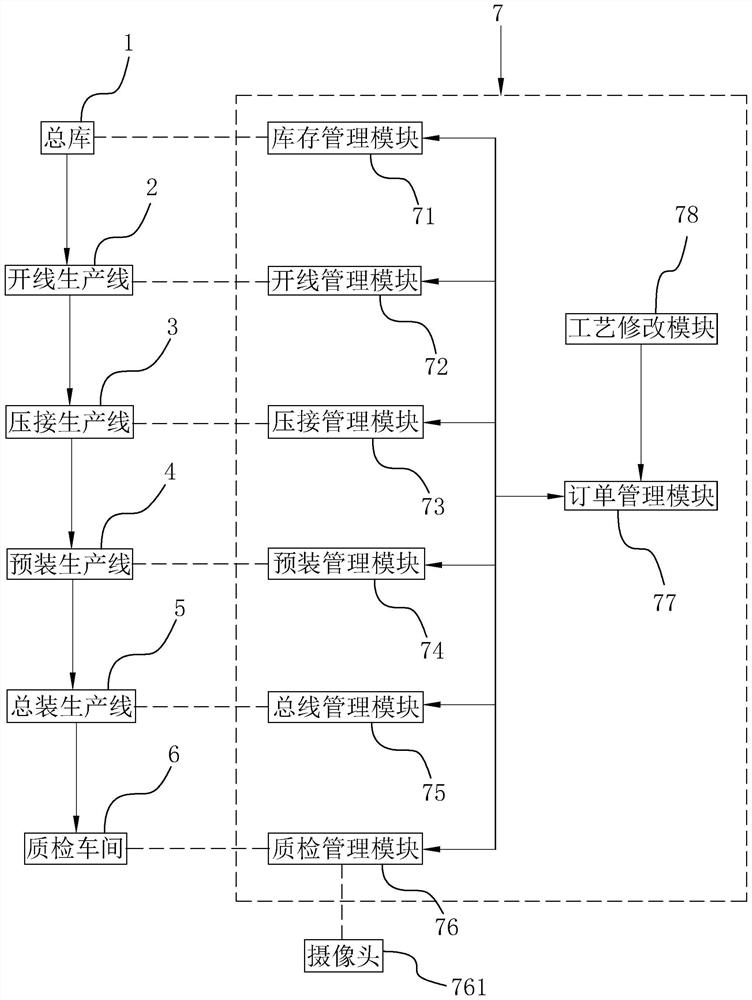

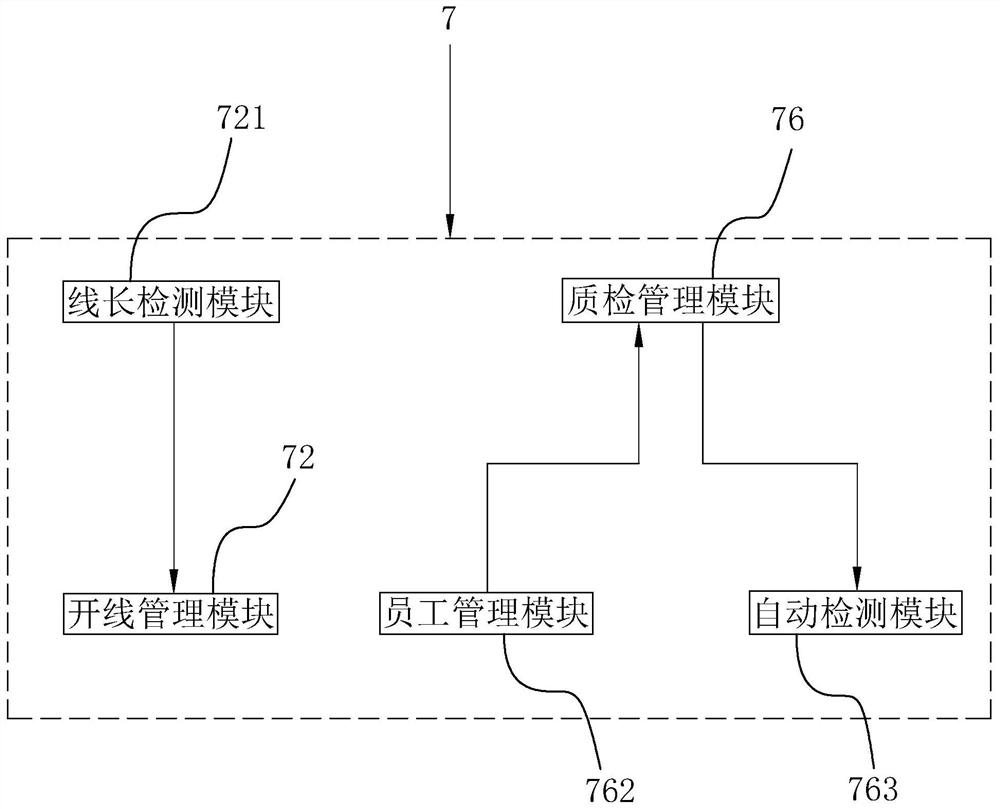

[0044] Embodiment: a kind of automobile wiring harness production management system, such as figure 1 and figure 2 As shown, it includes the general warehouse 1, the opening production line 2, the crimping production line 3, the pre-assembly production line 4, the final assembly production line 5, the quality inspection workshop 6 and the control system 7. The control system 7 includes an inventory management module 71, an open line management module 72, a line length detection module 721, a crimping management module 73, a pre-installation management module 74, a bus management module 75, a quality inspection management module 76, an employee management module 762, an automatic Detection module 763, order management module 77, process modification module 78.

[0045] Such as figure 1 As shown, the order management module 77 stores wire harness processing technology information. The order management module 77 receives the order information input from the outside and retrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com