Vulcanizing dead steam waste heat recovery device

A waste heat recovery device, a technology for exhausted steam, applied in the direction of heat exchanger types, lighting and heating equipment, direct contact heat exchangers, etc., can solve the problems of insufficient utilization and waste of energy, and ensure atmospheric discharge requirements, less volume, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

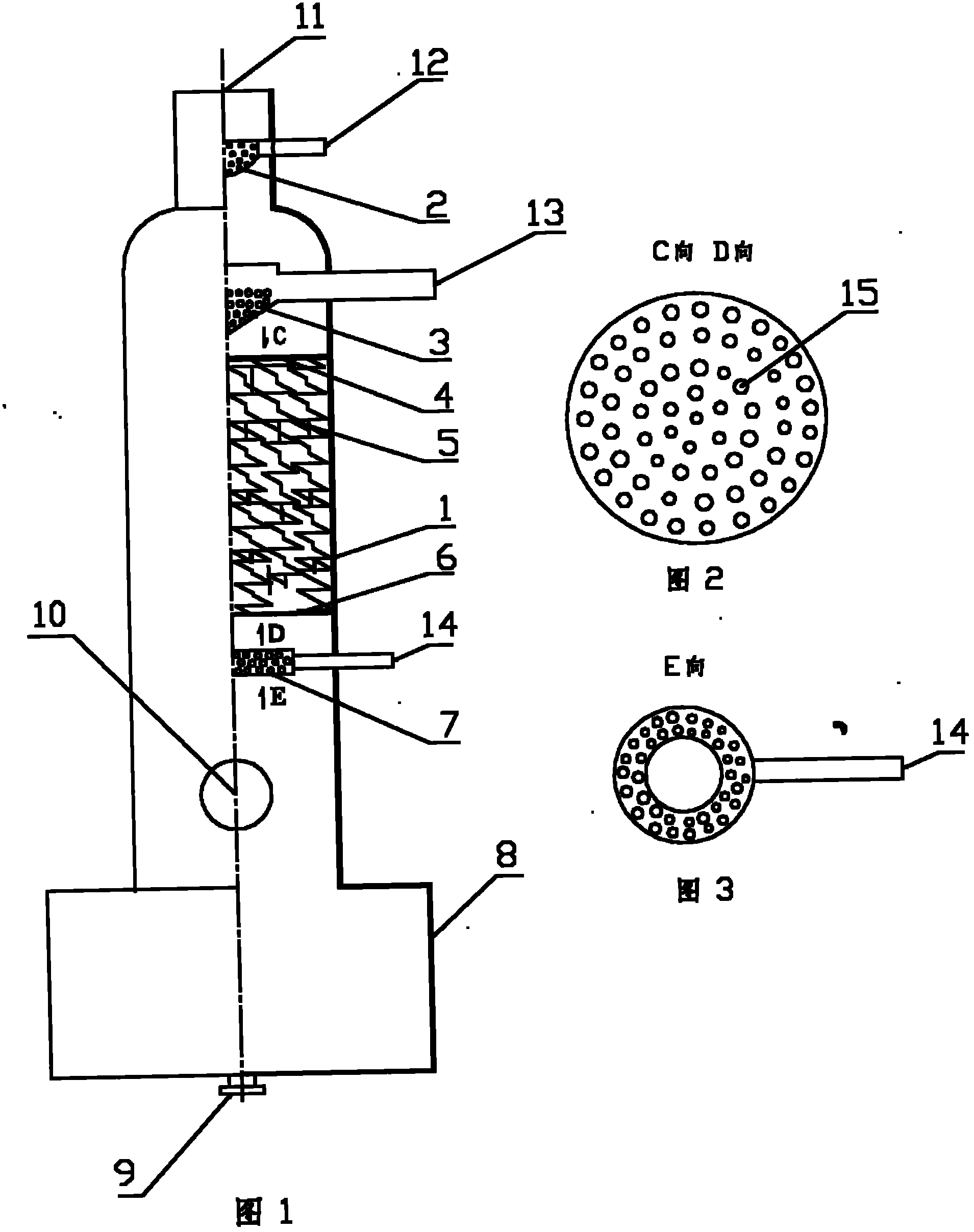

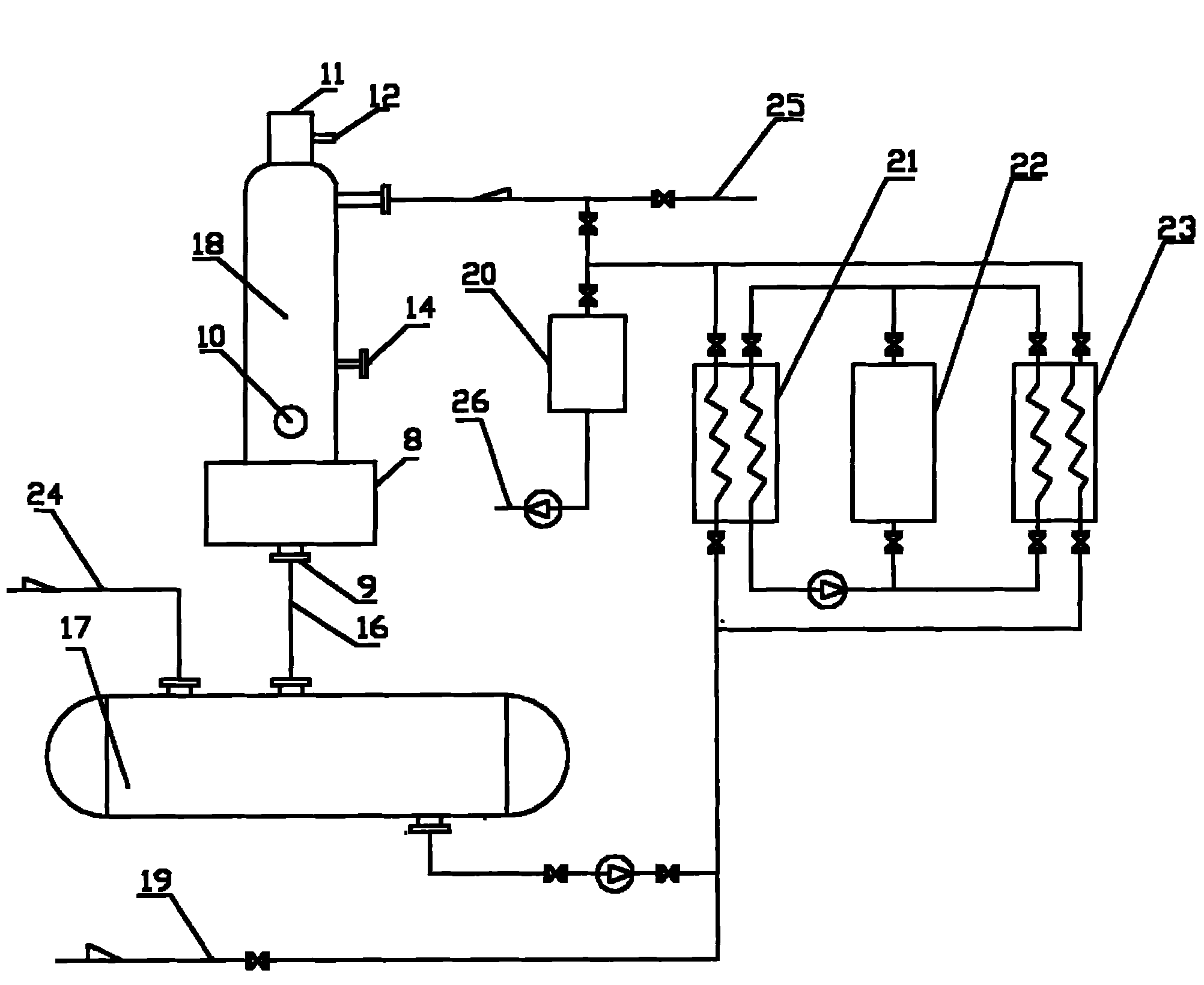

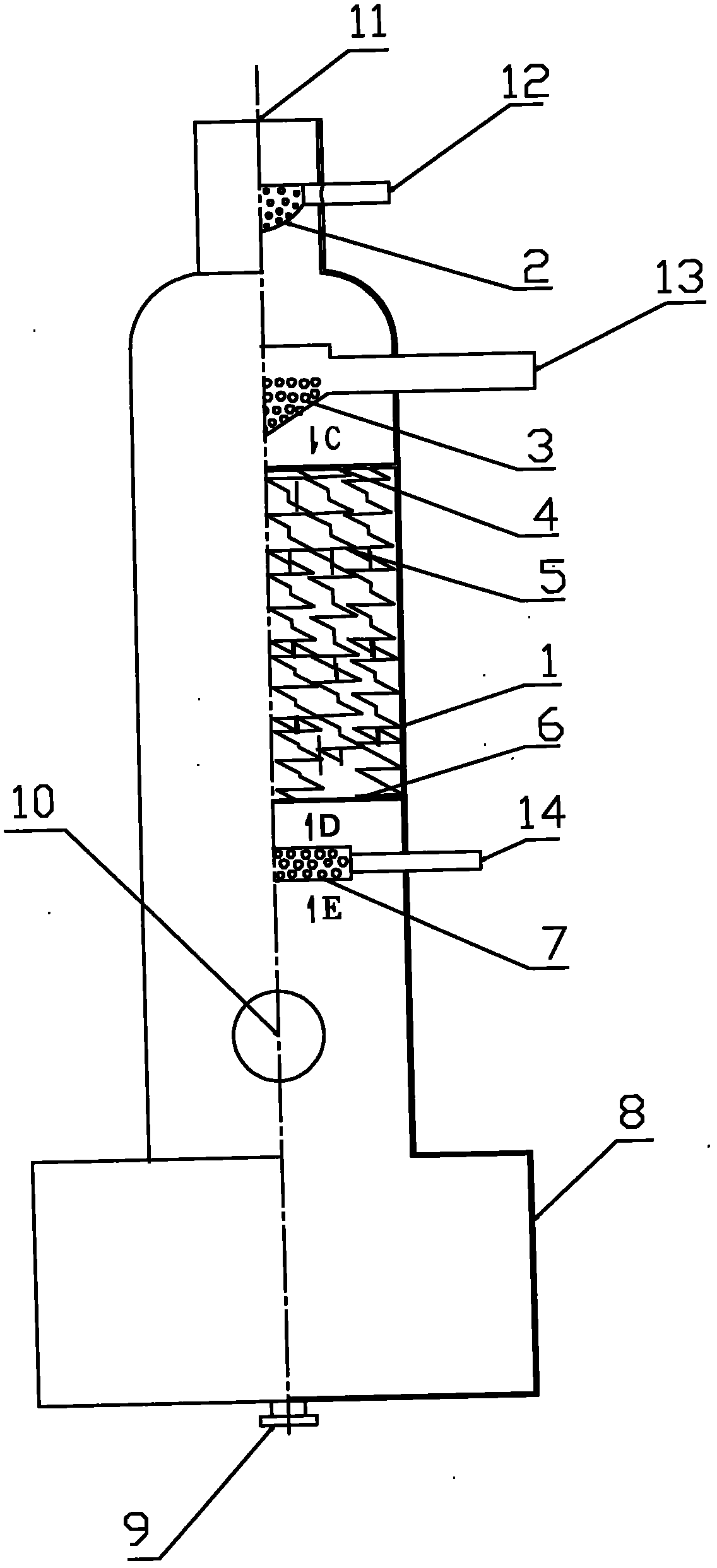

[0015] It will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0016] Such as figure 1 As shown, a vulcanization waste heat recovery and utilization device includes a exhaust steam heat exchanger 18 and a water storage tank 8. The exhaust steam heat exchanger 18 includes a shell 1, and a gas discharge port 11 is provided at the top of the shell 1. The bottom of the shell 1 A exhaust steam inlet 10 is provided, and the exhaust steam inlet 10 is used as the exhaust steam inlet of the vulcanization system. The bottom end of the shell 1 is provided with an integrated water storage tank 8, the water storage tank 8 is provided with a hot water outlet 9, the water storage tank 8 and the water storage tank 17 are connected by a pipeline 16, and the inner cavity of the shell 1 is sequentially provided with cloth Water device, membrane absorbing device and jet mixing device, described water distributing device is the 1st nozzle 2 of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com