Experience-feedback-based nuclear power equipment preventive replacement cycle optimizing method

An optimization method and preventive technology, applied in the direction of instruments, data processing applications, calculations, etc., can solve the problems of low reliability of reliability indicators, limited application, and few failure data, etc., to achieve reasonable and reliable methods and improve safety. applied effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

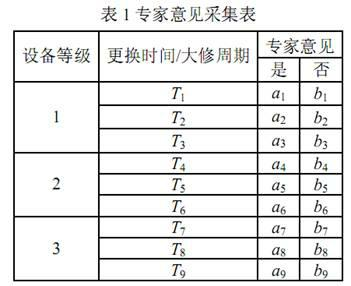

[0060] Two kinds of instrumentation switches were selected as the target equipment, and the opinions of 10 experts were sought, including electrical engineers, nuclear equipment appraisal engineers, equipment manufacturers, operation and maintenance personnel, etc. The results are shown in Table 2.

[0061]

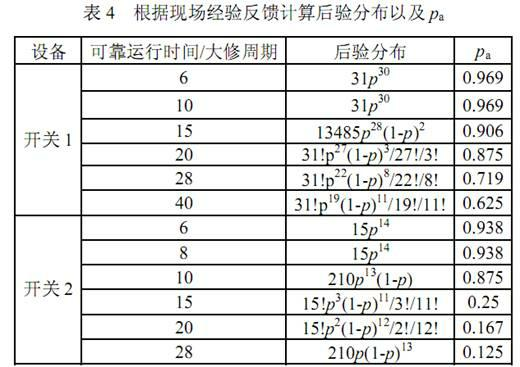

[0062] According to the calculation results in Table 2, the prior distribution and mathematical expectation can be calculated according to formula (6) and formula (8). p b , see Table 3.

[0063] According to the calculation results in Table 3, 10 years can be selected as the initial replacement period for switch 1, and 8 years can be selected as the initial replacement period for switch 2.

[0064] The following corrections are made based on actual operating experience. A total of 20 switches 1 were in use at the site. When the operation reached the 13th overhaul cycle, there was a failure once, and there was no failure record after that; there were 4 switches 2 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com