Nitrogen oxide absorbent

A nitrogen oxide and adsorbent technology, applied in the direction of alkali metal oxide/hydroxide, alkali metal compound, inorganic chemistry, etc., can solve the problem of low feasibility, low nitrogen oxide purification efficiency, investment, operation and maintenance The problem of high cost can achieve the effect of good treatment effect, ideal effect and convenient industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

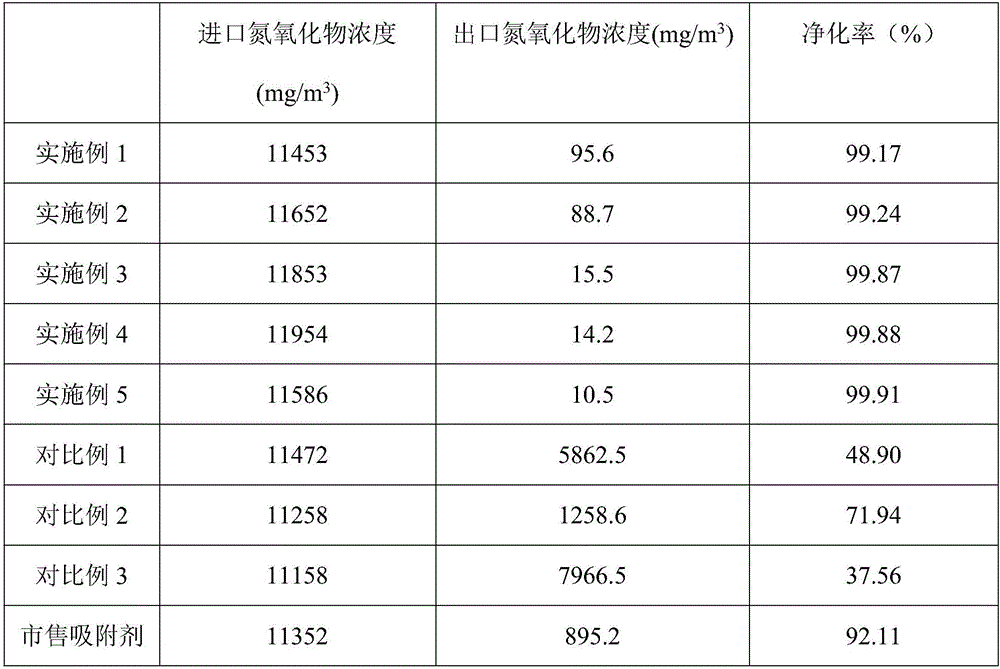

Examples

Embodiment 1

[0016] In the embodiment of the present invention, a nitrogen oxide adsorbent is composed of the following raw materials in parts by weight: 26 parts of nano-attapulgite, 9 parts of catechin, 5 parts of malondialdehyde, and 1 part of triethanolamine.

[0017] Mix malondialdehyde with 3.2 times the mass of ethanol to prepare a malondialdehyde solution; mix catechin with 8.3 times its mass in deionized water to prepare a catechin solution. Mix and grind nano-attapulgite and triethanolamine, add catechin solution, heat to 88°C and seal and stir at this temperature for 86 minutes, then add malondialdehyde solution, cool to 66°C and stir at this temperature for 52 minutes , and then lowered to 60°C and ultrasonically treated at this temperature for 33min with an ultrasonic power of 1000W, then stirred at a temperature of 98°C until dry, and then calcined in a muffle furnace at 430°C for 3.2h to obtain the adsorbent.

Embodiment 2

[0019] In the embodiment of the present invention, a nitrogen oxide adsorbent is composed of the following raw materials in parts by weight: 34 parts of nano-attapulgite, 17 parts of catechin, 13 parts of malondialdehyde, and 5 parts of triethanolamine.

[0020] Mix malondialdehyde with 3.2 times the mass of ethanol to prepare a malondialdehyde solution; mix catechin with 8.3 times its mass in deionized water to prepare a catechin solution. Mix and grind nano-attapulgite and triethanolamine, add catechin solution, heat to 88°C and seal and stir at this temperature for 86 minutes, then add malondialdehyde solution, cool to 66°C and stir at this temperature for 52 minutes , and then lowered to 60°C and ultrasonically treated at this temperature for 33min with an ultrasonic power of 1000W, then stirred at a temperature of 100°C until dry, and then calcined in a muffle furnace at 430°C for 3.2h to obtain the adsorbent.

Embodiment 3

[0022] In the embodiment of the present invention, a nitrogen oxide adsorbent is composed of the following raw materials in parts by weight: 28 parts of nano-attapulgite, 11 parts of catechin, 7 parts of malondialdehyde, and 2 parts of triethanolamine.

[0023] Mix malondialdehyde with 3.2 times the mass of ethanol to prepare a malondialdehyde solution; mix catechin with 8.3 times its mass in deionized water to prepare a catechin solution. Mix and grind nano-attapulgite and triethanolamine, add catechin solution, heat to 88°C and seal and stir at this temperature for 86 minutes, then add malondialdehyde solution, cool to 66°C and stir at this temperature for 52 minutes , and then lowered to 60°C and ultrasonically treated at this temperature for 33min with an ultrasonic power of 1000W, then stirred at a temperature of 99°C until dry, and then calcined in a muffle furnace at 430°C for 3.2h to obtain the adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com