Rolling device and method for cylindrical battery shell

A cylindrical battery and rolling line technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as battery failure, polluted batteries, and unpleasant odors, and achieve stable production processes, improve sealing effects, and improve quality products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0039] The batteries prepared in the embodiments of the present invention are all AA-type cylindrical lithium-iron disulfide batteries, and the preparation method is as follows:

[0040] FeS 2 The powder (natural pyrite collected from Yunfu, Guangdong) is used as the positive electrode active material, and the material is mixed with the conductive agent (graphite and acetylene black) to make the positive electrode powder. Use an organic solvent to make the adhesive into an adhesive, wherein the adhesive is styrene-ethylene / butylene-styrene block copolymer (SEBS, trade name Kraton G1651), and the organic solvent is produced by Shell A mixture of Shell A100 (aromatic solvent) and Shell OMS (isoparaffin) in a mixing ratio of 4:6 (by weight).

[0041] The above positive electrode powder and binder are mixed in a weight ratio of 2:1 and then stirred to form a slurry. In the dry matter of the positive electrode slurry finally made, the weight ratio of each component is:

[0042] ...

Embodiment 1

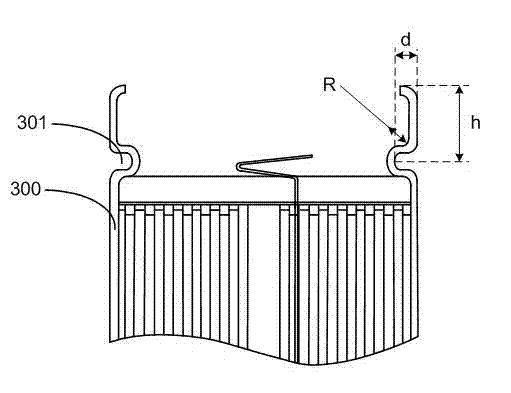

[0046] provide as Figure 2A-2B In the rolling device shown, 20 battery casings obtained in the preparation example were provided, divided into two groups of 10 pieces, and then rolled on the battery casings by using the three-wheel rolling process of the present invention. The rolling line height is 4.20mm, and the upper R angle is 0.65mm. The difference is that the rolling line depth of one set of battery cases is 1.10mm, and the rolling line depth of the other set of battery cases is 1.30mm. After the rolling line is finished, inject electrolyte, seal and make AA battery.

Embodiment 2

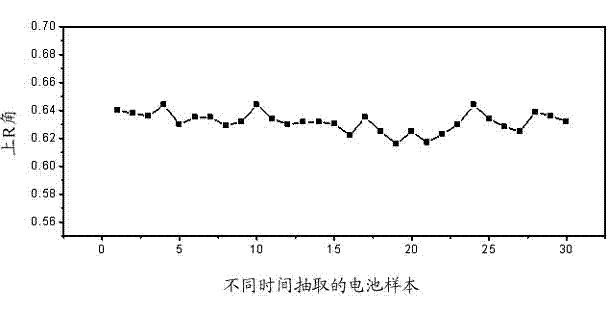

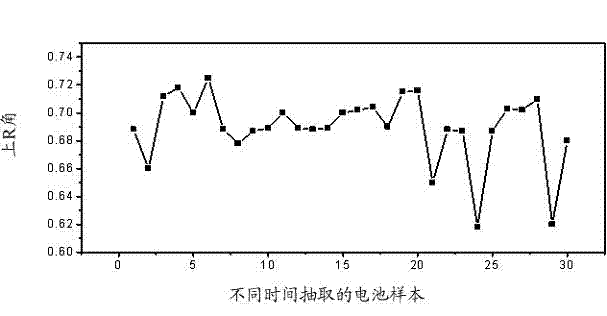

[0053] provide as Figure 2A-2B The rolling device shown is provided with 20 battery cases obtained in the preparation example, which are divided into two groups with 10 in each group. Then, the rolling line process of the present invention is used to carry out rolling line on the battery case. The rolling line height is 4.20mm, and the rolling line depth is 1.15mm. The difference is: the upper R angle of one set of battery cases is 0.60mm, and the upper R angle of the other set of battery cases is 0.70mm. After the rolling line is finished, inject electrolyte, seal and make AA battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com