V-shaped vertical windmill

A windmill and vertical technology, applied in the energy field of wind energy utilization, can solve the problem of wind wheel enlargement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1 3

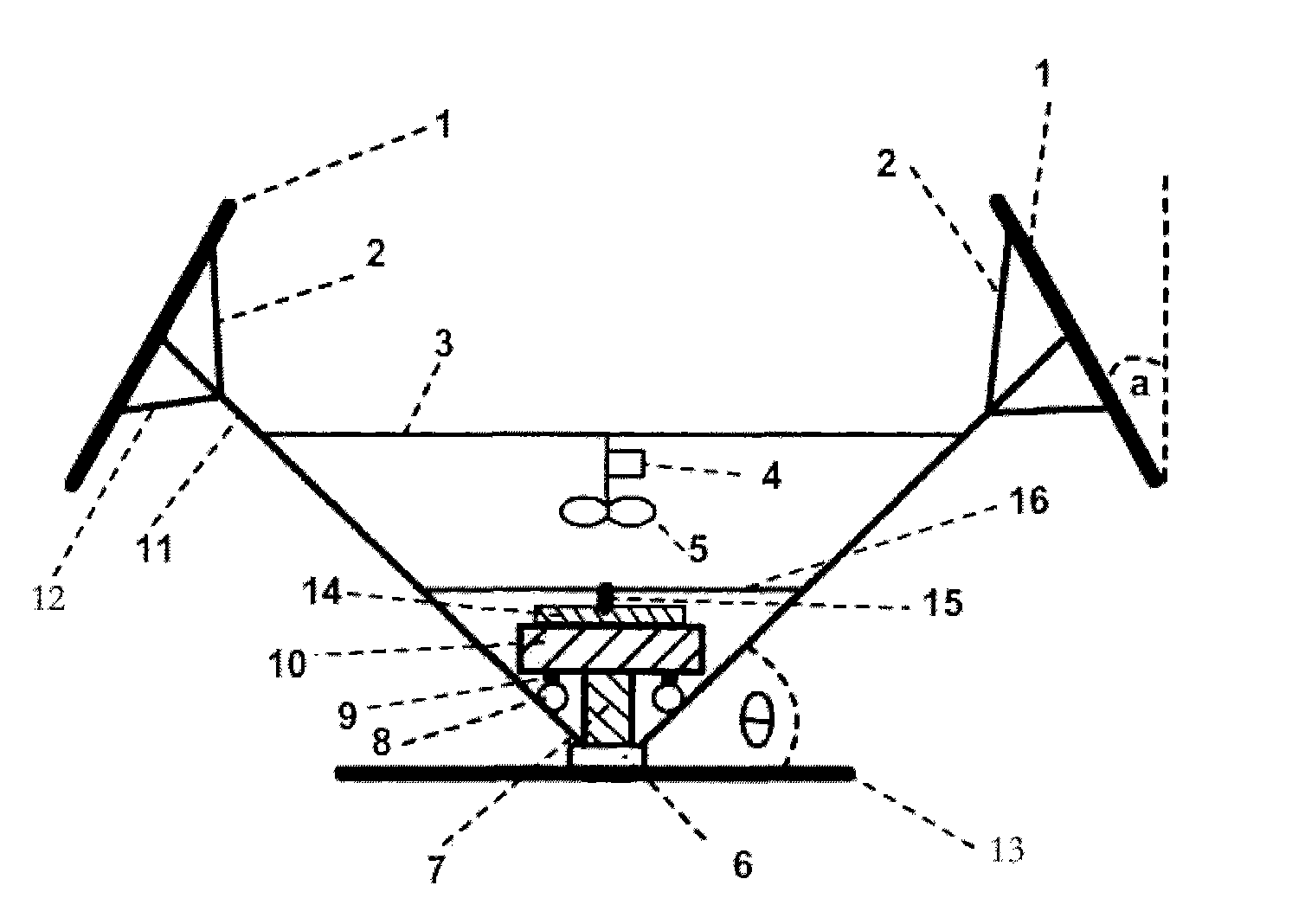

[0034] Example 1 Three-bladed V-type vertical wind wheel

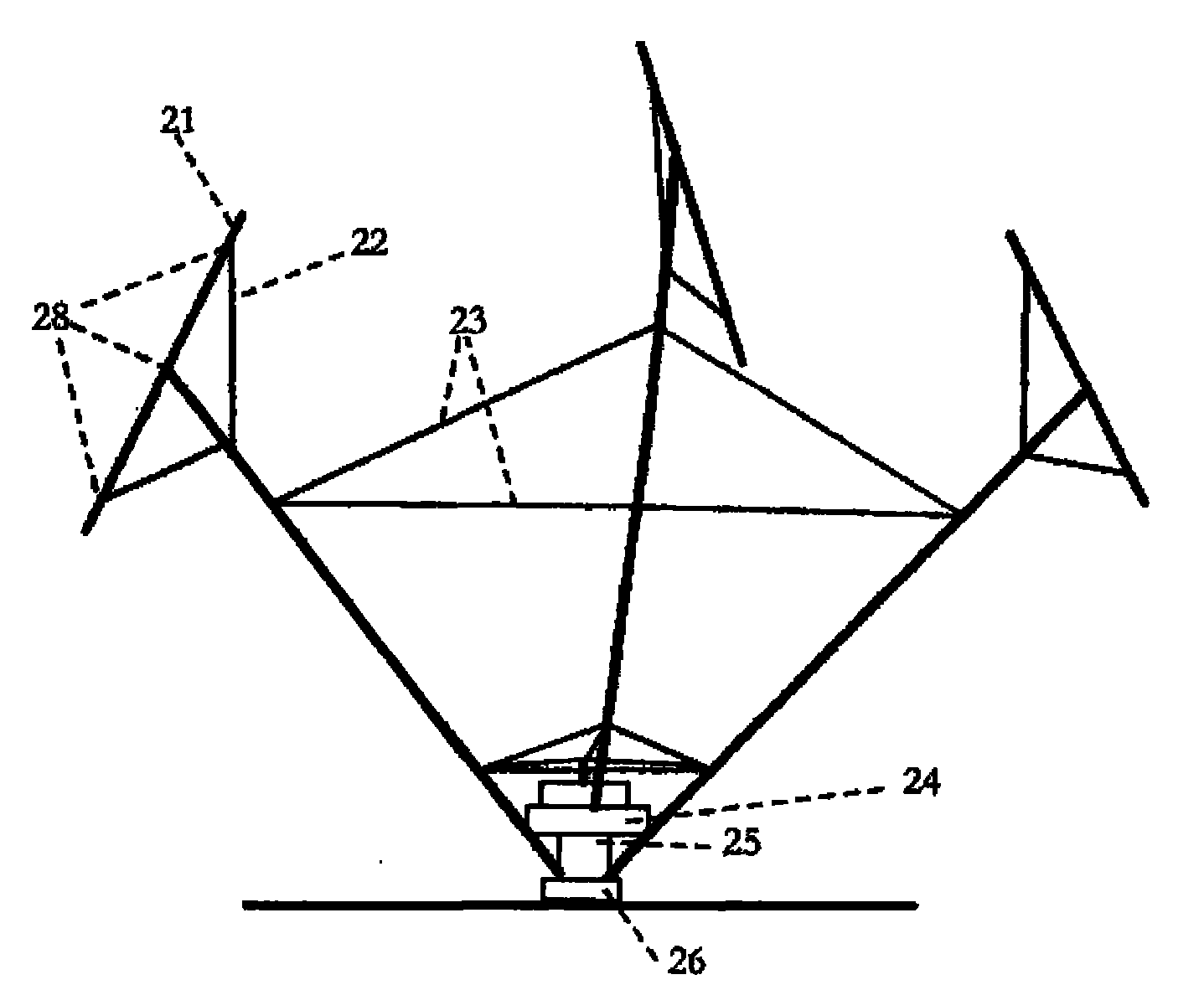

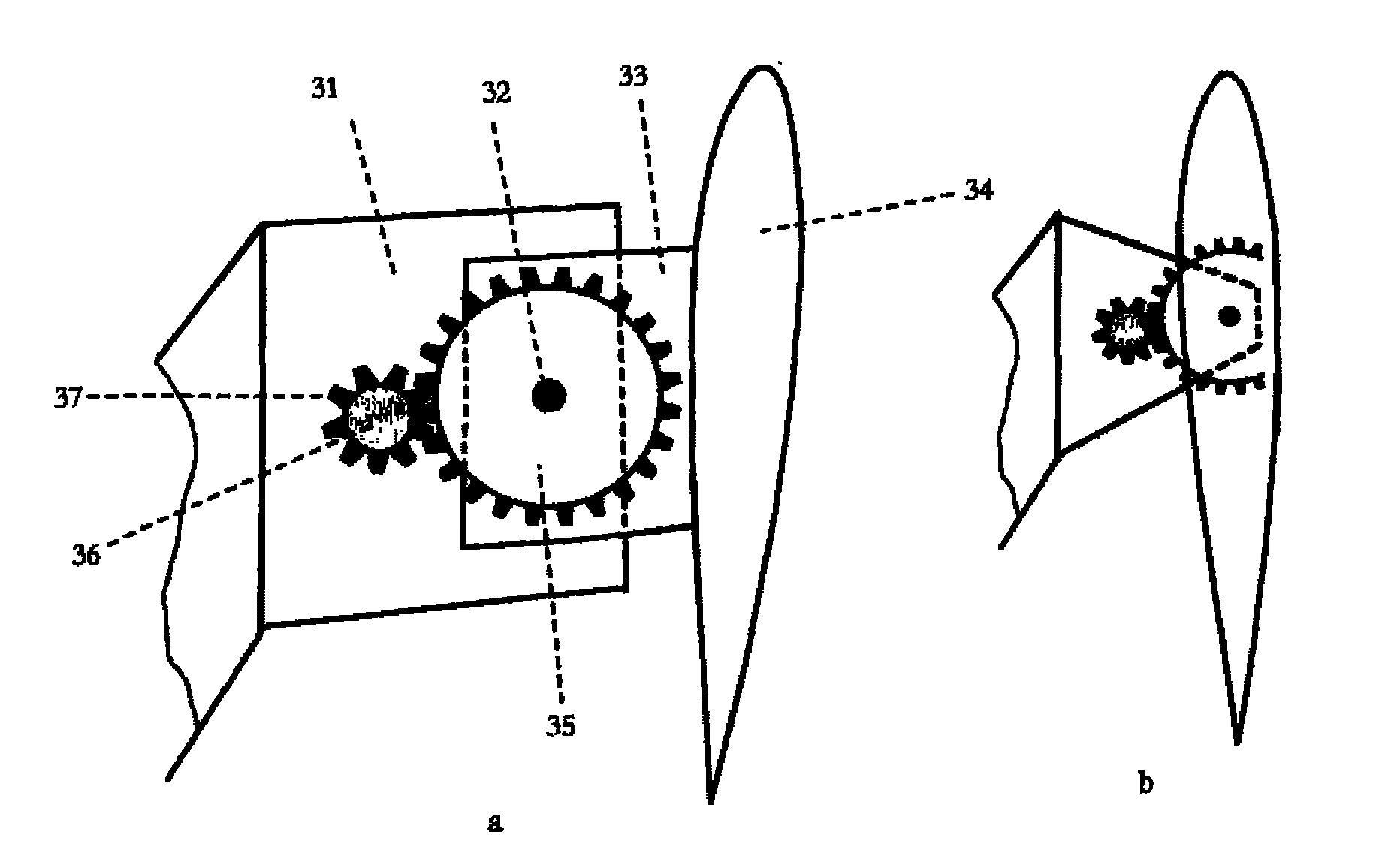

[0035] Its appearance and shape are as attached figure 2 shown. Its structural principle is as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 shown.

[0036] The wind wheel has the following figure 1 The oblique support arm 11 shown in , the angle θ between the support arm and the horizontal plane is 30-75 degrees, the auxiliary support arm 2 is installed on the support arm 11, and the inwardly inclined blade 1 is installed on the top end, the blade 1 The angle a with the vertical direction is 1 to 45 degrees. The lower end of the support arm is installed on a rotatable base 6, and a column 7 of a T-shaped column is installed in the base 6, so that the support arm can rotate around the column 7, T The shaped column is composed of a column 7 and a disc 10. On the lower plane of the disc 10, a ring rail 9 is installed, and at the position corresponding to the support arm and the r...

example 2

[0037] Example 2 The V-type vertical windmill when the generator replaces the T-shaped column

[0038] attached Figure 5 A schematic diagram of a 3-bladed V-shaped vertical windmill is shown. in the attached Figure 5 Among them, the connection 51 between the blade and the support arm is fixedly connected, and a disc generator is used. The blade support arm is installed on a rotatable base 55, and the generator rotor 53 is connected with the rotating base 55 and is located on the 55. The generator The stator 52 is installed on the rotor, and is connected with the base 54 through the shaft, and is fixed together. The windmill is a small windmill, so only two supporting points are provided between the blades and the support arms.

example 3

[0039] Example 3 V-type vertical windmill using "<" type blades and C-type blades

[0040] attached Figure 6 It is a schematic diagram of a V-shaped vertical windmill using " Figure 7 It is a schematic diagram of a V-shaped vertical windmill using C-shaped blades, and the connection between the blades and the support arm is fixedly connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com