Constant-temperature and constant-pressure inflation method and device of diaphragm capsule for temperature controller

A technology of constant temperature, constant pressure and temperature controller, which is applied in container filling method, equipment loaded into pressure vessel, gas/liquid distribution and storage, etc. Improve the measurement accuracy and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

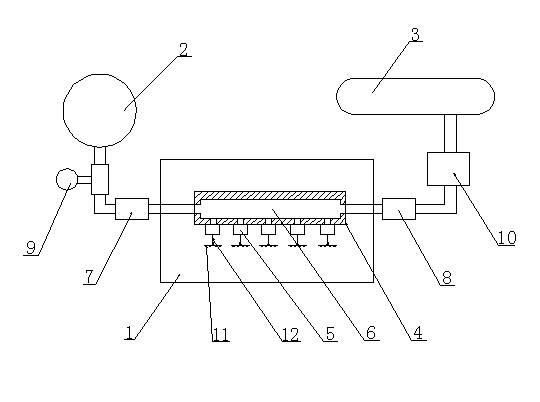

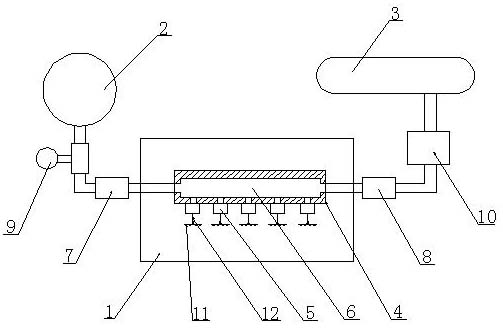

[0021] The constant temperature and constant pressure filling method of the bellows working medium for the thermostat is as follows:

[0022] Step 1. Put the bellows in the incubator, and clamp the capillary of the bellows on the bellows fixture, and adjust the temperature in the incubator to 40°C;

[0023] Step 2. Connect the capillary of the membrane box to the vacuum pump, start the vacuum pump to vacuum the inside of the membrane box, and the vacuum degree is 30Pa;

[0024] Step 3: After vacuuming, cut off the connection path between the capillary of the bellows and the vacuum pump, and connect the capillary with the air storage tank through the pressure regulator. Use the pressure regulator to adjust the inflation pressure of the air tank to 0.4MPa to inflate the bellows. Inflation ends when the pressure equalizes;

[0025] Step 4: Seal the bellows to complete the filling of the bellows with working fluid.

Embodiment 2

[0027] The constant temperature and constant pressure filling method of the bellows working medium for the thermostat is as follows:

[0028] Step 1. Put the bellows in the incubator, and clamp the capillary of the bellows on the bellows fixture, and adjust the temperature in the incubator to 60°C;

[0029] Step 2. Connect the capillary of the membrane box to the vacuum pump, start the vacuum pump to vacuum the inside of the membrane box, and the vacuum degree is 50Pa;

[0030] Step 3: After vacuuming, cut off the connection path between the capillary of the bellows and the vacuum pump, and connect the capillary with the air storage tank through the pressure regulator. Use the pressure regulator to adjust the inflation pressure of the air tank to 0.6MPa to inflate the bellows. Inflation ends when the pressure equalizes;

[0031] Step 4: Seal the bellows to complete the filling of the bellows with working fluid.

Embodiment 3

[0033] The constant temperature and constant pressure filling method of the bellows working medium for the thermostat is as follows:

[0034] Step 1. Put the bellows in the incubator, and clamp the capillary of the bellows on the bellows fixture, and adjust the temperature in the incubator to 50°C;

[0035] Step 2. Connect the capillary of the bellows to the vacuum pump, start the vacuum pump to vacuum the inside of the bellows, and the vacuum degree is 40Pa;

[0036] Step 3: After vacuuming, cut off the connection path between the capillary of the bellows and the vacuum pump, and connect the capillary with the air storage tank through the pressure regulator. Use the pressure regulator to adjust the inflation pressure of the air tank to 0.5MPa to inflate the bellows. Inflation ends when the pressure equalizes;

[0037] Step 4: Seal the bellows to complete the filling of the bellows with working fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com