Double-diameter spring type heat transfer pipe insert orifice fixing device

A technology for fixing devices and inserts, which is applied in the field of automatic rotary descaling devices for inserts in tubes of shell-and-tube heat exchange equipment, which can solve problems such as easy falling off, increased fluid medium resistance, and large nozzle area of the fixing device, reaching the scope of application Wide, small resistance, occupying a small nozzle area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

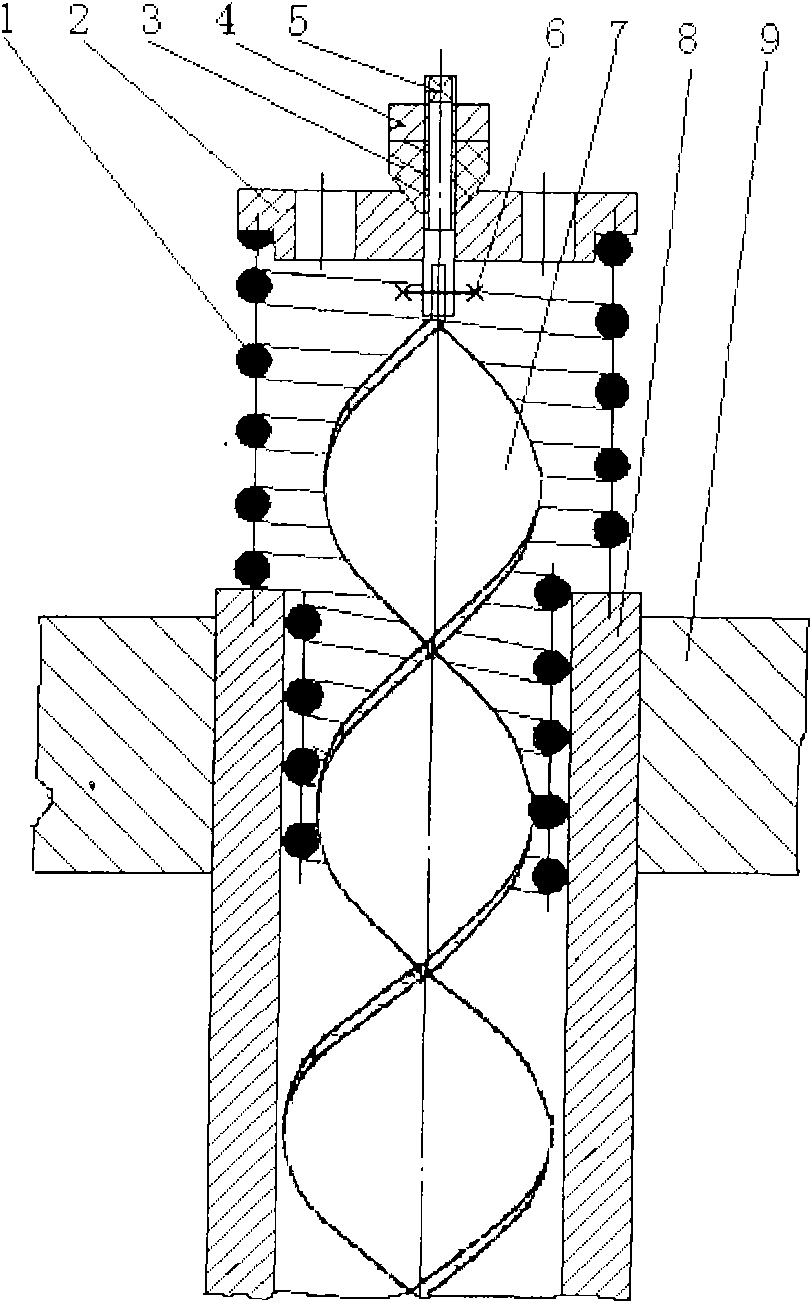

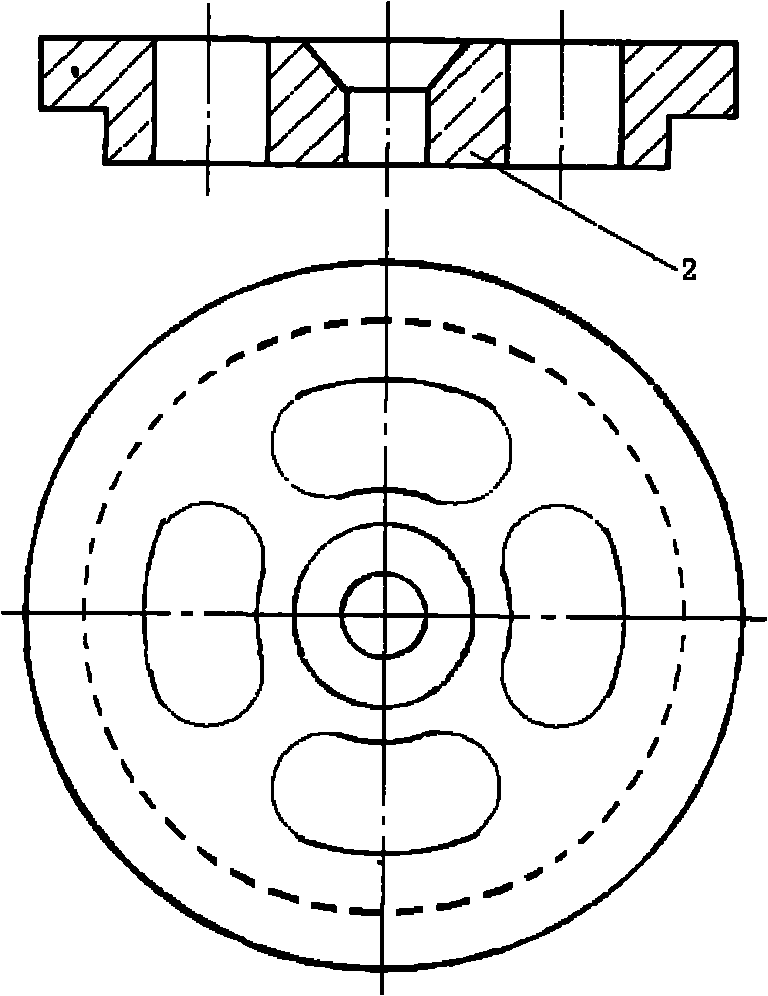

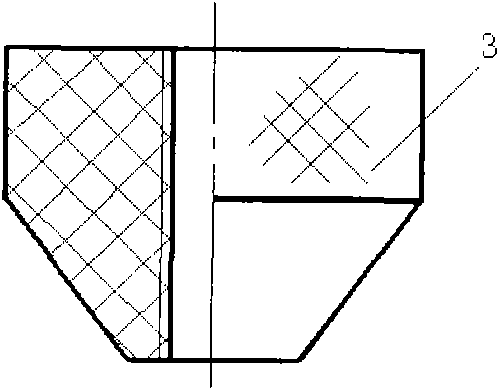

[0018] Such as figure 1 As shown, a double-diameter spring-type heat transfer tube insert nozzle fixing device, first insert the tube insert 7 into the heat exchange tube 8, and then insert it into the opening of the rotating shaft 5 and connect it firmly with bolts and nuts 6, and then insert the small-diameter end of the double-diameter spring 1 Part of it is firmly inserted into the nozzle of the heat exchange tube 8, so that the large diameter end of the double-diameter spring 1 is fixed outside the nozzle of the heat exchange tube 8, and then the spring seat 2, the axial bearing 3, and the lock nut 4 are installed in sequence, and finally the shaft It is enough to lock the bearing 3 and the rotating shaft 5 mutually. If this double-diameter spring-type heat transfer tube insert nozzle fixing device is used in a vertical shell and tube heat exchanger and the fluid medium flows from top to bottom, it only needs to be installed at the inlet end of the heat exchange tube 8. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com